Fullerton Tool Company drives tremendous savings for its global clientele in solid carbide cutting tools. That is why leaders in the medical, aerospace, and other manufacturing industries are lining up for its tooling range of 7,000 standard items—most notably, its end mills—famed for strength, durability, and accuracy. Customers come from the United States, South America, Mexico, Canada, and beyond for the company’s dependable tools.

The company also offers advanced tool engineering. Just under half of its orders are for custom-engineered tools.

Fullerton is agile enough to deliver goods rapidly, and material quality is of the utmost importance. The company’s tooling is made from premier carbide material, and can be supplied with high quality coatings for added performance and longevity.

The company was established in 1942 by Morgan Arthur Curry, a 1932 graduate of the University of Michigan. Curry built a company known for its integrity, concern for customers’ well-being and success, and a lot of hard work. Today, his work ethic is sustained by a team of industry professionals solidly invested in what they do.

At home in Saginaw, Michigan, the company’s latest new tool is the 3125 V-MAC, a high-speed, high-output end mill. This powerful piece of tooling offers optimal flute engineering, minimized vibration, enhanced tool stability, a leading anti-fatigue coating, and advanced chip control that creates superb cutting edges.

The 3125 V-MAC “is the best high-performance end mill we’ve ever made in 80-plus years of our existence. So, we proudly named it after our founder and grandfather, Morgan Arthur Curry,” says Patrick Curry, President. “So far, for people who have implemented it, it has saved hundreds of thousands of dollars because of the tool life and the speed they can run it at.” The product is popular among aerospace engineers for use with high-temperature titanium alloys and similar.

The company’s second shining success is the 3500SM Micro Fury, a high-performance subminiature end mill rendering first-in-class surface finishes and specializing in high-output, high-speed, full-diameter milling. Great for use on titanium, steel, and super alloys, the unit also boasts an advanced chip evacuation feature.

Fullerton invests time and resources to ensure that its website is as comprehensive as possible. With instant quotes that generate pricing and lead times for custom and altered tooling, extensive tool search capabilities on standard tooling, and speeds and feeds calculator, there is nothing this boundary-pushing team has not thought of. “Our website is a market leader in providing useful tools to our customers, from selecting the right product to the correct way to apply the product,” says Curry. “It’s a very user-friendly, innovative website that makes our customers’ lives easier.”

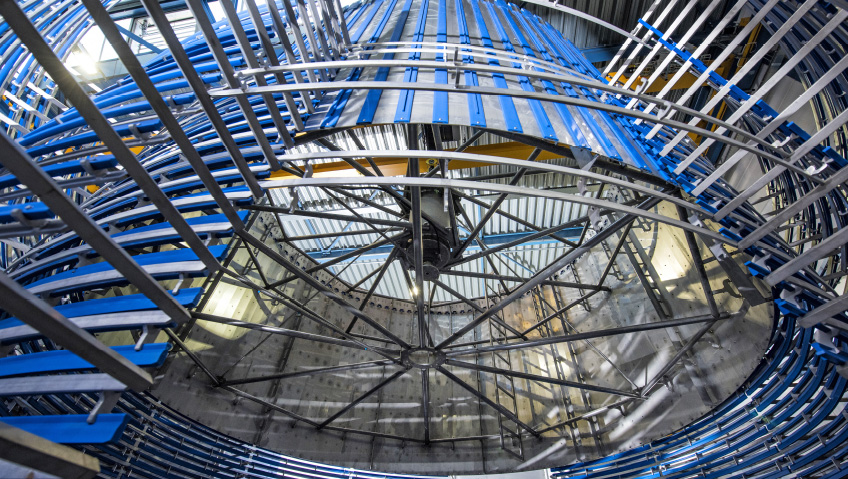

The company has also made extensive investments in its facility. Some new technology it introduced recently includes a 3D CNC Tool measuring machine and two Walter helitronic Vision 400L computer numerical control (CNC) grinders, giving the company the highest precision grinding and measuring equipment in the industry.

Fullerton’s customer service is also exceptional, providing quick answers and an average turnaround for quotes of just three to four working hours. Fullerton’s Advanced Solutions Team (F.A.S.T.) finds speedy solutions and optimizes everything from lead times to cost and material savings. Fully equipped with a next-generation research and development laboratory, the F.A.S.T. team is adept at innovation.

Increasing its staff numbers by more than 30 people in the past three years, Fullerton has around 215 people on its team—a mix of baby boomers, whom Curry refers to as “the greatest generation in manufacturing,” and promising younger minds embracing the latest technology and bringing fresh ideas to the firm. A few fourth-generation employees recently joined the company’s ranks, making its leaders very happy.

In addition, “We are extremely blessed with some great women in manufacturing. They’re leaders in our company, and they’re phenomenal manufacturers… It’s impressive to see,” Curry says. “It’s a big differentiator for us, especially when we’re competing against some global competitors who don’t take advantage of hiring talented women in their companies. We’re very excited about the women leaders we have.”

Building a healthy work environment where people are happy to arrive each day is at the forefront of Fullerton Tool Company’s list of priorities. The company boasts a robust human resources department, regular surveys and newsletters keep management and staff aware of what’s going on, and transparency and continuous improvements in workplace happiness are as big a part of the company’s plans for the future as its growth.

Another point of difference for Fullerton is that it functions from a scientific perspective. While a longtime Lean Six Sigma operation, the company also employs other valuable systems to keep it at the forefront of manufacturing. The Entrepreneurial Operating System (EOS) is an invaluable planning tool that assists leaders in developing a clear roadmap for their businesses while cultivating healthy business practices and organizational psychology to drive employee engagement that, in turn, translates into considerable gains for customer satisfaction. Based on the company’s ‘Five Ps’—namely, people who care, the principles of loyalty and dedication, a passion for personal development, precision, and productivity—employees are clear on how to reach their personal and professional goals.

The investment is worth it. “Recently we’ve had some really big orders. The team stepped up. We’re really proud of the teamwork and everybody collaborating to get the job done. It’s something to be proud of,” Curry says, pointing out how impressive it is to realize the team’s strength despite tremendous challenges and changes over the past twelve months—not to mention COVID-19.

The changes have not stopped Fullerton from growing its charitable work with organizations like Power of Dad, which supports young men with fatherly guidance, and Saginaw Rescue Mission, which helps people who have fallen on hard times.

Looking further afield, “We see some good opportunities picking up internationally,” Curry shares. “The United Kingdom, Ireland, and Europe are where we are seeing some good growth opportunities.” He notes a strong market trend toward engineering single multi-tools rather than multiple tools, making for a pleasant reduction in the cost of ownership.

Then there is Fullerton’s 2042-Plan, a 19-year mission to reach its 100th anniversary intact, bigger and better than ever. The family is also stepping up. Recently, the company welcomed Patrick Curry’s son Aiden, niece Grace, and business partner’s niece Whitney Miller, a passionate woman invested in learning and appointed as Regional Sales Manager. Working her way up from the bottom of the company, Miller worked in almost every department, sometimes getting her hands pretty dirty along the way.

“Her grandpa and great-grandpa would be very proud of her. I know her dad and her mom would be as well, and we are too. She’s a great example for the other family members in the business,” says Curry. “We are fired up about having some of our family members joining us. It’s nice having them taking this seriously and wanting to make an impact and help grow Fullerton, taking it to the next generation,” he adds, proudly.