From concerns about plastic pollution in oceans to sustainability, our collective viewpoint on the future health of the planet and its almost eight billion inhabitants is changing, and the Chemistry Industry Association of Canada is a leader behind that change.

In Canada, one of the industries most surrounded by misconceptions is chemicals. The third-largest manufacturing sector in the nation, chemistry is vital to the country’s economic health, providing thousands of direct and indirect jobs. Touching everything from green energy initiatives like solar panels, wind turbines, and electric vehicles to textiles, electronics, consumer goods, life-saving medicines, and much more, chemistry and plastics are crucial to the livelihood and well-being of all Canadians.

Although 70,000 different products Canadians use daily employ chemistry and plastics in their manufacture, some detractors believe the industry is old, stagnant, and heading the way of the dinosaurs. The truth is, it would be hard to imagine a more vibrant, innovative, and varied one.

Nothing without chemistry

“The reality is, if you can see it, feel it, touch it, and taste it, it’s been touched by the business of chemistry,” says Bob Masterson, President and CEO of the Chemistry Industry Association of Canada (CIAC). “Estimates are that 95 percent of all finished products have been touched by the business of chemistry.”

Masterson is passionate about his role and furthering the mission and objectives of the Association and the country’s many plastics and chemical companies. With the Association for 13 years in total—five of them as Vice President—Masterson has a deep knowledge of the sector, its history, and its goals.

One of the biggest myths about Canada’s chemical sector is that it is stagnant, but the truth is very different. Since the Second World War, the worldwide chemistry industry has grown at about one and a half times the global gross domestic product (GDP), and not only is it outpacing global GDP, but it is accelerating for several key reasons.

As populations increase worldwide, especially in Asia, the demand from the growing middle class for more products made using chemistry and plastics rises. Likewise, there is a greater demand for sustainable outcomes such as clean air and water, abundant food, and medicines, none of which can happen without chemistry. Manufacturing green products, like wind turbines and solar panels, requires chemicals, as do electric vehicles.

The vital role of plastics

Everything we do daily requires plastics and chemicals, something many people aren’t aware of. While some say we should do away with plastics in grocery stores, they are vital to a greener planet. Not only are plastics used to protect and display food, they are much lighter than alternatives like glass, requiring less fuel for transportation and resulting in fewer greenhouse gases.

“The drive is for more plastics, which are energy- and water-efficient to produce and have a lower environmental impact in production and transportation than alternatives,” says Masterson.

To be sure, the chemistry industry is changing, and CIAC is a proud leader of that change. Representing the country’s leaders in chemistry and plastics, the Association is influential with federal and provincial levels of government, helping to shape public policies impacting everything from sustainability to innovation, and from the economy to the environment.

The mission of CIAC’s plastics division is to establish a circular economy for plastics in Canada. While there are many definitions of “circular economy,” the Government of Canada considers it to be about ways of using valuable resources wisely and re-considering waste as a resource, not a cost.

“In a circular economy, nothing is waste,” according to canada.ca. “The circular economy retains and recovers as much value as possible from resources by reusing, repairing, refurbishing, remanufacturing, repurposing, or recycling products and materials. It’s about using valuable resources wisely, thinking about waste as a resource instead of a cost, and finding innovative ways to better the environment and the economy.”

Manufacturers, and society itself, are demanding smarter and better ways of doing business, and one of the conditions of membership in the Chemistry Industry Association of Canada is that all members sign up for two circular economy goals.

“We’ve all heard the expression, ‘the buck stops with us.’ In this case, it’s the opposite: the buck starts with us,” comments Masterson. “Job one is to design materials that can be recycled, and not enough attention—in the past—has been paid. Goal number one by 2030 is the industry making products that are 100 percent designed to be recycled.”

Design for recycling

To date, one of the challenges has been the many functions plastic packaging serves on grocery store shelves. More than a means to display product and label information, plastic pouches often need to accomplish up to seven different functions, such as branding, keeping out moisture and light, allowing customers to see the contents, and more.

Until now, if the plastic pouch had to serve seven different functions, it often needed seven different laminates, and could not be recycled. As a greater step toward sustainability, the industry is developing mono-packaging, making plastic pouches out of one type of plastic meant to go into blue boxes. Another goal is working with governments to ensure 100 percent of plastic packaging is recovered and recycled by 2040.

“Again, the future of the industry is a circular economy for plastics,” remarks Masterson. “That means plastics that go into the economy are used by the consumer and can be recovered and reused. We have a recycling system in Canada, but what people have come to realize—and have been frustrated by—is that it recovers and recycles only about 12 percent of plastics nationally. It’s awful.”

The way recycling has been carried out for years Canada-wide has made matters even more confusing. Until recently, there were 256 different blue box systems just in Ontario. Municipalities had different requirements and competed for market share.

Then, starting in British Columbia about six years ago, the transfer of responsibility shifted back to the private sector. All companies putting plastics into the economy now have to pay a fee per kilogram to an arm’s-length government entity which collects the money, operates recycling systems, hits regulated targets, and is charged with improving recycling, including by educating the public. In the next three years, Ontario will follow BC’s lead and transition to a smaller number of very large recycling programs across the country, with money going solely to recycling.

Before around 2017, British Columbia was averaging 20 percent recovery and recycling of plastics. Thanks to their stepped-up efforts, the province is now closing in on 50 percent, with a goal of 75 percent. An impressive 98 percent of material recovered is recycled into other products in the province.

“We estimate there are $6 billion to $8 billion of plastics that would go into landfill every year,” says Masterson. “Being able to recover those keeps things out of landfill, prevents litter, and reduces emissions in other parts of the economy when we don’t have to make original products. We can recover these post-consumer products and process them, so it’s a win for the economy, the environment, and for taxpayers.”

Responsible Care®

Every year, CIAC releases Delivering on Our Commitments, a report on its members’ commitment to the international and UN-recognized sustainability initiative, Responsible Care® (https://canadianchemistry.ca/wp-content/uploads/2023/06/Sustainability-Report_ENG_v7.pdf). A requirement of membership for CIAC, Responsible Care compels members to complete third-party audits of their operations on safety and sustainability, report on and continually work to reduce emissions of harmful chemicals, and support safe, sustainable and resilient transportation infrastructure.

Founded in Canada almost 40 years ago, Responsible Care is practiced today in 73 nations worldwide and by 96 of the world’s biggest chemical producers. Recognized through the United Nations’ environmental, social, and governance (ESG) initiative, Responsible Care companies “strive to the ethic to ‘do the right thing and be seen to do the right thing,’” according to the report.

It goes on: “Our dedicated members are constantly innovating and working toward safer and greener products and processes, and work to continuously improve their environmental, health, and safety performance.”

Nowadays, the entire world is focused on sustainability in chemicals and plastics. At present, a global treaty on plastics—much like the case with climate change—is being developed.

“We’re not quite sure what that will end up looking like because we are about halfway through the process, but the Government of Canada is a key contributor and leader in that, so whatever happens, Canada will have an influence and the outcomes will be felt by industry and citizens here in Canada,” shares Masterson. “Next April, the global negotiations come to Ottawa, and it’s the next-to-final lap of negotiations that they expect will lead to a global treaty on plastics.”

Future of the industry

Across the nation, Canada’s chemical industry continues its rapid expansion, although there is still some catching up to do.

Globally, the sector invests over $50 billion a year in capital for new infrastructure. Over the last 10 years, over $300 billion of new chemistry investment has gone into the United States alone; in fact, half of all manufacturing investment went to the chemistry sector in the U.S. in the last decade. Over that time, Canada should have realized 10 percent of that amount, about $30 billion of new investment. The figure is actually much less, about $7 billion.

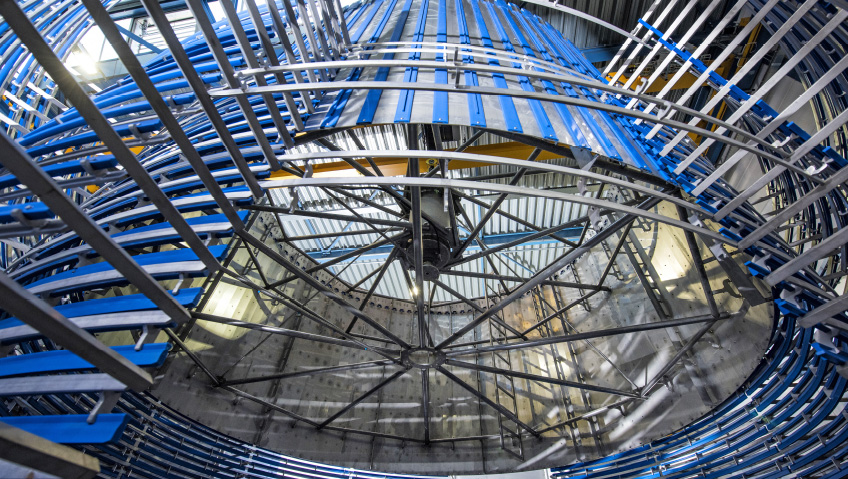

Fortunately, there are new facilities in the works. Nova Chemicals has a plant coming online in Sarnia, Ontario this year, and a new polypropylene plant from Inter Pipeline just got underway in Alberta. And if all goes to plan, Fort Saskatchewan, Alberta will be home to the world’s first and only Net Zero petrochemical facility.

According to Dow Chemicals, the proposed Fort Saskatchewan Path2Zero expansion project “will create the world’s first net-zero carbon emissions integrated ethylene cracker and derivatives site with respect to scope 1 and 2 carbon dioxide emissions.”

Still subject to approval by Dow’s Board of Directors and different regulatory agencies, the project’s many benefits would include decarbonization of about 15 percent of Dow’s global ethylene capacity “while growing polyethylene supply by about 15 percent… produce and supply approximately 3.2 million metric tonnes of certified low- to zero-carbon-emissions polyethylene and ethylene derivatives for customers and joint venture partners around the globe,” and, “add approximately 1.8 million metric tonnes of ethylene capacity in a phased manner through 2030.”

Says Masterson, “Not only are we looking to finally capture some of this investment growth that’s gone to all the other countries worldwide, but we’re also looking at it as making a significant contribution to decarbonization of our sector in the broader Canadian economy. It’s a really exciting time for the chemistry industry in Canada. And again, part of that ties back into a better realization of the importance of this industry.”