With all of the recent advances in AI and machine learning, modern speculative fiction has us poised for either robotic-enhanced utopias or machine-overlord dystopias, depending on an author’s level of optimism. But the reality in the manufacturing world is a shift from floor space largely filled with people to production and warehouse spaces being shared with robots in a variety of roles.

As automation of formerly manual processes becomes the new normal through robotics and software, what does this mean for the people working on factory floors? Are the robots taking away jobs or are they instead opening more opportunities for people in manufacturing? Good question.

To start, automation in manufacturing is nothing new. In fact, rudimentary automation has been part of manufacturing since the 19th century. Back then, though, people would literally attack the new devices and destroy them to try to prevent losing work (not a great time for employee-employer relationships). And since that time, there have always been short-term spikes of unemployment when new innovations are introduced to industries like manufacturing—but the story doesn’t end there. While automation does replace a certain amount of work, if often opens alternative opportunities as a result.

The Asian Development Bank recently provided data that new technologies, including automation, had a net positive result on employment, displacing 101 million jobs but adding 134 million jobs between 2005 and 2015. And a 2020 study out of the Institute for Manufacturing at the University of Cambridge in the UK looked at South Africa’s apparel manufacturing industry, interviewing companies and finding that in many cases, automation has and is predicted to increase employment by boosting productivity.

Breaking it down, there are three main ways automation can be incorporated into a manufacturing process. There’s fixed automation, where the automation produces a singular product within a process; picture a particular machine producing a highly used but fairly simple part over and over again. Then there is programmable automation, where a program is used to dictate what a given machine does. These machines can do more than fixed automation, including sequences of steps. From there, the automation gets more advanced. Flexible automation is programmed automation, but these machines are able to adjust to design requirements. A central computer manages these processes as opposed to individual machines programed for specific tasks.

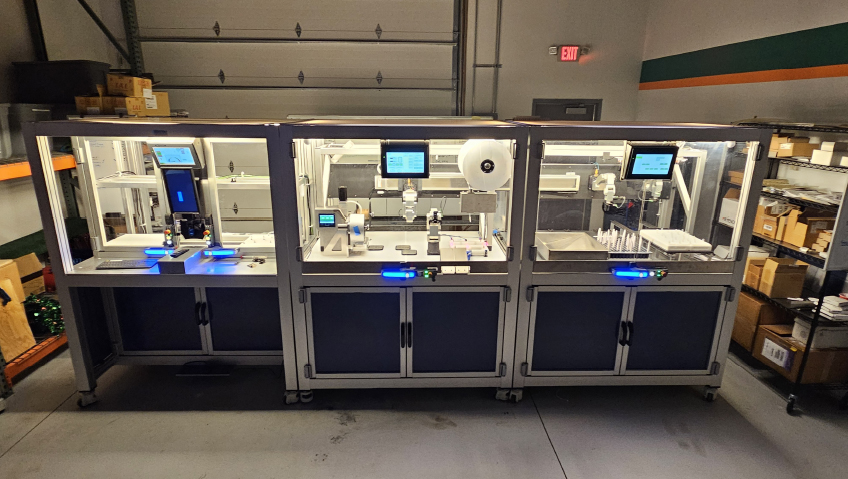

On top of this, for the past several years we have been experiencing a major shift in manufacturing as a whole. Known as Industry 4.0, AI, machine learning, and automation now come together on manufacturing floors. These smart factories are equipped with sensors, and software runs the robotics and ultimately collects data, monitors the machines, and analyzes all of these for better performance.

And while all these changes and advancing technologies can be exciting to some, they can be quite frightening to others. But in more cases than not, automation, AI, and advanced technologies are improving how people work and are creating new opportunities in the manufacturing industry.

In a blog post for nonprofit public policy organization, The Brookings Institution, Georgetown University Professor Harry J. Holzer notes how automation both gives and takes away from workers. First, there are the new opportunities that arise from advancements in automation. Those who are in a position to work with the machines will often see their see wages rise as they take on new roles to ensure that the robots keep turning out the widgets. But, for those people who either compete with machines or are replaced by machines, they will be worse off and need to upskill.

Holzer notes, “The ‘new automation’ of the next few decades with much more advanced robotics and artificial intelligence will widen the range of tasks and jobs that machines can perform, and have the potential to cause more worker displacement and inequality than older generations of automation. This can potentially affect college graduates and professionals much more than in the past.”

But it’s not all doom and gloom. According to the International Federation of Robotics, less than 10 percent of jobs can realistically be completely automated. Robots that can remove the mundane, repetitive tasks from a process and make the overall work experience more interesting, or those that can take on more of the dangerous work and tasks that require heavy lifting, are more useful. Companies are looking for automation solutions that not only keep people out of harm’s way, but also help them avoid injury from repetitive, strenuous work.

As Kriti Sharma, Vice President of Bots and Artificial Intelligence at Sage Group, an accounting and payroll company, says, “Things will get more accessible. These technologies will never replace the human beings, but they will relieve human beings of the things that are less valuable, and [human beings] will be able to focus on those things that require creativity and touch. We’ll see more accessible, better experiences and we’ll see human beings move to their highest and best value.”

The impact of automation goes beyond job losses or job gains to job changes. A concrete example of this is that Amazon workers who once lifted and stacked things in the warehouses are now becoming robot operators who are monitoring the automated arms and troubleshooting issues that come up with the robots. The retail giant’s new Sparrow robotic arm, for example, can pick up and sort millions of individual unpackaged products in tasks that used to be the exclusive domain of warehouse employees. Sparrow uses computer vision technology to identify and pick up the small products.

As Amazon’s Vice President of Global Robotics, Joseph Quinlivan, wrote in a blog post, “Robotics technology enables us to work smarter—not harder—to operate efficiently and safely.”

So what does this actually look like and mean for people who are working on a manufacturing floor—and what is changing in how they do their jobs?

For a better grasp on this, we can go back to where modern manufacturing started, on the Ford assembly line. Today, Ford is working with a robotics start-up called Symbio Robotics which uses computers and sensors to control the movement of the arms. This form of automation has been part of auto assembly lines for some time now, but it’s the added dimension of AI that has allowed robotics to fine-tune more processes than before, including quality control.

Not only does the combination of human and robot work in the manufacturing process, Ford has also incorporated robots in the mapping of its manufacturing floors. Human handlers work with YouTube stars, Boston Dynamic’s robotic dogs, to create 3D maps of a plant floor in nearly half the time it would take to complete the process in the past.

It’s clear that automation does help the bottom line, which is what companies are all about. By its nature, automation saves time and money, but it also allows companies to better position employees in needed areas, creating more fulfilling jobs. What is unclear is how advances will impact the future of work. Right now, as AI and related technology continue to advance, workers need be open to developing different skills than they had in the past, with greater focus on creativity, communication, and analytic skills.

So, we are clearly in a time of rapid change for the role of worker in the industry. The work world of tomorrow will undoubtedly be different from what we have experienced in the past, but by embracing that transition through education and skills development, we can help make it a positive change.