With Innovative Machining, LLC, securing comprehensive custom solutions and component fabrication services is as easy as setting up a call. Over a nearly three-decade legacy of putting independence first, this company has been focused on the future from the day John Milanowski first opened the doors of its original 3,000-foot facility twenty-eight years ago. Today, the result of that vision has culminated in an offering so complete that customers needn’t even think of turning elsewhere to fulfill any part of their fabrication process.

At home in Neenah, Wisconsin, Innovative Machining offers contract machining and fabrication solutions with assembly and paint shop capabilities, rapid lead periods, all-week fabrication output, and fast set-up strategies. The company’s wealth of third-party relationships also means that everything from anodizing, gear cutting, grinding, heat treating, painting, plating, and much more is performed to top standards under the watchful eyes of its knowledgeable industry professionals.

This, in addition to its ISO 9001:2015 certification, makes the company a favorite amongst equipment leaders in the medical, defense, marine, and automation industries, and even off-road recreational vehicle fabricators with on-demand component requirements. The team is proud of its considerable, diverse customer base and justifiably so. It is trusted to deliver high-end components when and where customers need them most. While the company has a strong presence in the Midwest, it serves all of the United States and Mexico.

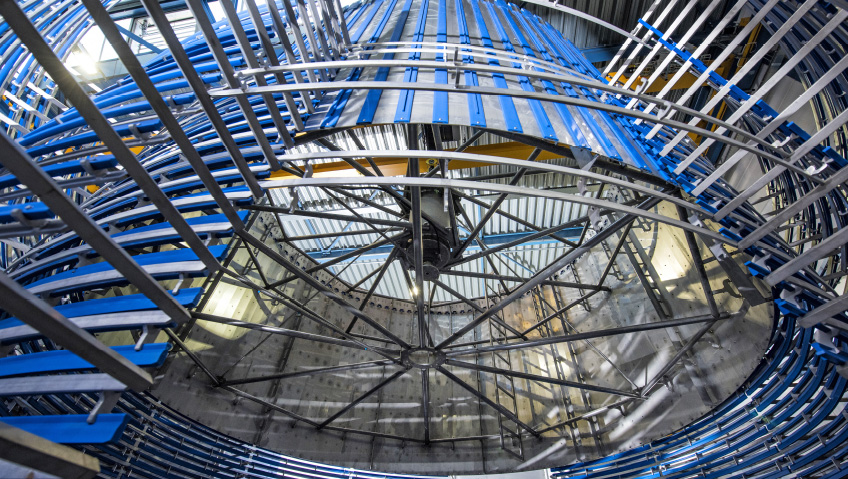

This powerhouse is also well-known for prototyping parts. The company has become especially known for hard-wearing metal frames for MRI scanning equipment used in the medical industry.

“Having all services under one roof sets us apart from competitors. We can offer lower-cost products because we don’t have to keep on sending parts to another supplier to complete another part of the process,” says President Marc Jankowski.

The fabricator’s 125,000-square-foot facility’s capacities are breathtaking, handling parts that weigh up to 44,000 pounds, with computer numerical control lathes capable of turning material measuring around 22.8 inches in diameter and 80 inches in length. It also does four-axis machining with rotary tables and palletized manufacturing.

As its founder had instilled such a sense of self-reliance into the company’s culture, it sailed through COVID-19 with comparative ease and remained as in demand as ever. Despite being retired, the founder/owner visits the plant regularly to keep an eye on things and ensure that its culture continues to go from strength to strength. As the company’s vast range of capabilities continues to grow, adapting to whichever industry is most robust within any given economic timeframe is easy. This astute approach to business also won the Fox Cities Chamber of Commerce Small Business of the Year Award in 2010.

The expertise of the roughly eighty staff members is, of course, a necessary addition to achieving a customer’s goal in the way they had envisioned it. Innovative Machining employs people with diverse skills and knowledge to ensure that, no matter what a client needs, there is an expert at hand to assist.

A dedicated quality manager monitors specifications, ensuring that these meet standards. To guarantee good communication, contributors meet in-house to discuss the goals and specifications and map the most appropriate plan of action at the beginning of new projects. These meetings are followed by weekly meetings to keep projects on track.

The proactive team never stops evolving, and neither do the machines. One machine in particular enables creators to set up six, independently-run projects instead of only two, which was the maximum capacity on the older model of this specific machine.

“Not many shops can say that they have as many skilled machinists as we have,” says Jankowski. In January 2022, the company installed a Hexagon Metrology Global S coordinate-measuring machine, bringing its fleet of these workhorses to three. The new arrival allows its quality laboratory to assess much bigger components. Alongside this, a new scanning probe has also been installed and adds improved sophistication to its measuring capabilities.

In addition, it installed a Colonial vertical pull-down broaching machine that significantly increased its output volumes. This machining process uses a toothed tool to remove material. The company also bought a vertical machining center last year. The Mazak VTC-250D is a 50-taper with Mazak’s SmoothG Control and will reapply to billet prototyping projects. “All our new equipment generates a lot of excitement from all our employees, especially those who have been with us for over ten years,” says Jankowski.

As well as its recent investment in modern equipment, the company continuously welcomes new talent to its floor. To draw the best people possible, the shop floor is kept as clean and comfortable as possible, and the fabrication facility is air-conditioned in the summer.

“We worked a lot on organizing our shop, making sure everything is orderly and people have a clean work environment. It has come to be a good company culture that we’ve built here,” Jankowski adds.

People earn good money here and overall remuneration packages are attractive. Salaries are in the top quarter across the region, and its benefits rank in the top ten percent in the same geographic area. The company also offers a 401(k) plan with a company match. In addition, it adjusts salaries annually according to its financial situation, at a minimum always covering inflation.

Innovative Machining is also affiliated with a local college, where novices are sent to gain more education once they have finished their apprenticeship program. Based on their performance, the company pays for that too. With as many as six apprentices currently concluding the apprenticeship program, the approach is proving successful and worth every dime.

These investments reflect in the quality of work that constantly brings in new customers and keeps old customers returning. Recently, a customer in the medical equipment trade even brought over work that was half-finished by another firm that could not deliver on the specifications.

“It was quite a success story in that we are delivering them a better product now… and it was a good team effort internally to provide them with a superior product,” Jankowski says. At Innovative Machining, employees’ voices matter, and everybody’s ideas are always considered.

In the eyes of the company’s leadership, the team’s work ethic is second to none. “Our people take their work seriously. They want the company to succeed. It is amazing how involved they want to get in making sure that the projects succeed,” he continues.

This commitment has translated into very steady growth. By continuing to grow its team, its equipment, and its capabilities, Innovative Machining is setting itself up for considerable future success.