Great customer service, loyal customers, awesome products and services, sustainability, and automation are hallmarks of Packaging Systems (Indiana based) and Small Quantity Boxes (Wisconsin based). These powerhouse packaging, corrugated box, supplies and associated machines & service companies have merged to serve their customers with the same business ethics and happy, quality service-minded employees for which they have been famous. Packaging-Systems.com & SmallQuantityBoxes.com: A Winning Combination.

Packaging Systems provides packaging solutions with efficient and sustainable shipping costs, while Small Quantity Boxes manufactures custom and stock packaging using high-quality raw materials. Both companies excel at building strong customer and employee relationships.

The recent acquisition of Small Quantity Boxes, which is now a brand of Packaging Systems, is part of the “House of Brands” approach where Packaging Systems is cognizant of the power and value of maintaining goodwill and identity established over a period of years. Keeping powerful and recognized brand names helps with loyalty and maintaining customer comfort and peace of mind about the changes. The two businesses are working to offer stronger, more efficient service to combined clients, a move both Pat Tharp, President of Packaging Systems, and Dennis TeGrootenhuis, President of Small Quantity Boxes (SQB) applaud.

TeGrootenhuis was a packaging designer before deciding to go out on his own. He immediately showed his business chops, growing his business, hiring employees, and achieving impressive success: Small Quantity Boxes recently celebrated its 30th anniversary.

While the SQB niche is smaller quantities, the company’s powerful work ethic and drive for customer satisfaction translates into exactly what needs to be done to keep clients coming back and referring even their competitor friends who also need high quality, low quantity special corrugated boxes for specialty and trial new product developments.

“A number of years ago, right before our Christmas party, Kimberly-Clark wanted 2,000 boxes the next day. We all came in after the party and got them done. Kimberly-Clark was thrilled with us and is still a good customer… One of our main focuses was and still is running those quantities of 50 to 500,” says TeGrootenhuis. “I think what’s propelled us even more in this industry is the larger corrugated manufacturing companies now look at the minimums of 1,000 for quantity, so that’s raised our level more where we’re running 600 or 700 quantities to be competitive in that field.”

For example, Small Quantity Boxes can digitally print 200 boxes without a print plate, and die-cut boxes without a die board, allowing printing of multiple colors and pictures without the typical “set-up charges” assessed by high volume production facilities. When people need high volume then Packaging Systems picks up the job and proceeds to deliver high quality packaging by the truckload and more! The merging of Packaging Systems and Small Quantity Boxes can serve the full range of packaging volume needs for their current and new customers.

Prior to the merger, TeGrootenhuis received numerous calls from business brokers but was not interested in selling his company to investors. He and Pat Tharp of Packaging Systems, however, were connected through a mutual friend.

“Over the past five years, when people asked me, ‘what are you going to do – are you going to sell down the road?’ I said, ‘I’ll know it’s right when it’s right,’ and I knew this was right,” says TeGrootenhuis. “It’s because our morals, values, how we treat employees, and some of the vision all lined up. It was fantastic. I couldn’t have asked for anything better than meeting Pat and Kasey and merging the two companies.”

Kasey Clevenger, Vice President, Sales for Packaging Systems, agrees. “The thing that excited Pat and me so much about Dennis’s business is he listened to the market and to his customers, and he found a way to solve their problems.”

That’s also at the root of what Packaging Systems tries to do every day, Clevenger says.

“What we saw, for one, was a company that aligned with how we go to market. Secondly, the upside was that he had control of a product that would allow us to broaden our options to a combined 4,000 customers between the two companies. And it just seemed like a natural fit culturally. It’s that compatible culture that cemented the merger.”

“That was the driving point,” agrees Tharp. “When you get into acquisitions, the cultural fit has to be synonymous for both companies to work. We saw a culture at Dennis’s company that was very similar to ours at Packaging Systems.”

Even with multiple locations, Packaging Systems considers itself a small family-owned business that treats employees with respect and kindness.

“I think the average tenure at our company is well over 20, or even 25 years, and the same thing with Dennis’s employees,” says Tharp. “That longevity tells you a lot. We have the same synergies with our employees, and most of the time when an employee comes on board with us they feel like they’re part of the team.”

While both businesses have certain procedures they follow, they also have a flexibility that allows for employee and customer individuality, expression, health and well-being.

“Every day, we do what it takes to make our employees comfortable and happy to be a part of our team,” says Tharp. “We also really take care of our customers who are the lifeblood in our organization.”

While companies need to make a profit to stay in business, it’s important to keep customer needs a priority and always do what’s right. You can do both.

“Helping customers and always doing the little things that we can help them with goes a long way,” says TeGrootenhuis. “I know that it’s the same way with Packaging Systems. That’s what really drew me to them in our general conversations.”

That’s not to say Tharp and TeGrootenhuis always agree, but it’s how they disagree that counts, adds Tharp.

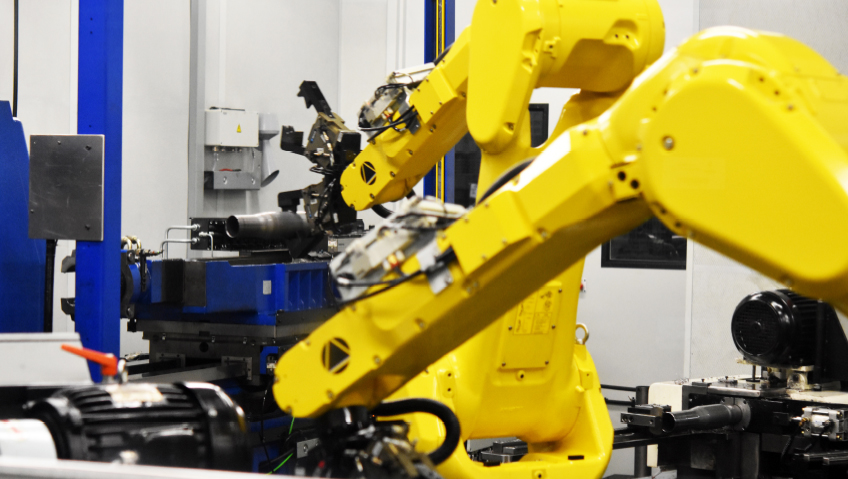

One thing they do agree on, however, is the importance of automation, and their ability to help companies with deficiencies or challenges they’re facing, especially right now. To that end, they’ve partnered with a robotics company that helps drive out a lot of waste.

“Our clients have been asking for help during COVID – this past two years… it’s been tough,” says Tharp. “I’ve heard throughout our plants that 30 percent of labor doesn’t show up on a daily basis. The amount of stress that brings is tough. People are tired right now. I’ve never seen so many managers out on floors working.”

Packaging Systems’ ability to put vital automation in place has been a dominant feature recently, with the implementation of about 15 robotic applications offering solutions that are “paramount.” The company also submits a Continuous Improvement Packaging Plan (CIPP) after a thorough review and analysis of all levels of packaging, to find products to reduce the total cost of doing business.

“We come in and also look at automation needs and our ability to drive out waste and bring in solutions to sustainability,” says Tharp.

Sustainability is at the forefront of both companies, which is where Packaging Systems’ sister company Hoosier Recycling plays a vital role.

“What makes us unique in the marketplace is we have the capabilities to prescribe environmentally acceptable packaging to our clients. We are very in tune with what is acceptable in the packaging arena, with keen awareness of environmental standards. We have helped several companies get to ZERO LANDFILL by our team approach and initiation of effective recycling programs,” says Tharp.

“It is imperative, for a long term sustainable plan, to have the recycling process done at the point of waste generation. For example: we sell a ‘stretch film mini-baler’ that takes the air out of the film after it is pulled off a load and the operator just sticks the film in the machine instead of a trash can. In the end there is a compressed block of ready-to-recycle stretch film with great value and less cost to accumulate than anything heretofore.”

Most of the recycling that happens within plants is in the packaging arena. Packaging Systems helps customers set up a working system, often selling them the equipment required for an effective recycling plan.

“Our motto is: Lowest Cost Per Load Effectively & Environmentally Shipped. For example, Packaging Systems recently sold a stretch-wrapping system to a client that will reduce the amount of film used on each load. The customer was hand-wrapping every unit in the facility with about one pound of wrap. This not only caused huge amounts of labor but created enormous waste and inefficiency. Hand-wrapping pallets not only added a pound’s worth of film to each, but that pound of stretch film was going out into the environment. Packaging Systems’ solution reduced that amount to a third of a pound,” says Tharp.

“The same customer is on the west coast, so they’re a green company looking for initiatives to promote those causes,” says Kasey Clevenger. “Packaging Systems strategically sited both a corrugated baler and two stretch-film mini-balers within the facility so whenever any type of plastic is removed, it immediately goes into that baler. Any leftover boxes go into the corrugated baler, essentially creating a closed loop. Everything then leaves their facility in a manner that parallels their corporate goals.”

“Corporate recycling initiatives are in the quality control documents, the ISO 9001, and they now physically have to do things to show to their shareholders and employees that they are in compliance,” Tharp says. “Recycling initiatives have really picked up over the last two years.”

TeGrootenhuis agrees. “Our customers are the same. They’re looking at going green, so any way we can help we do, even with just getting materials. You’ll find much of the corrugated board is 100 percent recycled.”

Although the past few years have been challenging, particularly about the supply chain and rising prices, both companies have made innovation a priority for themselves and their customers.

“We just don’t come in and say here’s your price increase,” says Tharp. “We’re always trying to come in and say, there is an alternative, don’t you want to take a look? I think we do a pretty good job of that.”

Striving for good, solid partnerships with customers and vendors is at the forefront of the companies’ operations – and has been for years – and is something both companies pride themselves on achieving. They represent over 300 different manufacturers in the packaging world.

“The partnerships we’ve formed with vendors all this time gave us a leg up,” says Clevenger. “When people see cost increases, they remember those 30 years and how we treated them throughout that time; that we weren’t just somebody trying to buy a product, mark it up and sell it in the marketplace. We were truly trying to form relationships throughout the business cycle.”

Moving forward now means keeping those relationships strong while celebrating a large and positive transformation.

While the merger is an accomplishment, growth is the milestone that matters. The future looks good and growth has been steady for 30 years for both Packaging Systems and Small Quantity Boxes.

“The blending of the two companies has been really neat to watch,” says Tharp. “So has the long tenure already of almost everybody at the two companies, especially considering the state of today’s marketplace.”

“You just have to be creative,” says TeGrootenhuis. “If there’s an issue or problem with employees or vendors, then we’re not happy. So how can we make this work and make it pleasant for everybody; retain our employees; have a great environment?”

Answering the question from TeGrootenhuis, it’s clear that a great environment will persist for the foreseeable future thanks to the happy blending of like-minded businesses that both owners anticipate will thrive for years to come.

Those years of knowledge, experience, and positive company culture are hard to beat.

“It makes us a very hard company to compete against,” says Tharp.