Proudly serving clients for the past 35 years, Anaheim Precision Manufacturing (APM) is active in aerospace, defense, technology, medical, communications, commercial, retail and other demanding industries. An approved supplier for some of the biggest names in business, like Boeing, Goodrich Aerospace, Honeywell International, Gulfstream, Sikorsky Aircraft Corporation, Zodiac, Rockwell Collins and Raytheon, APM provides engineering, milling, assembly and other services all in-house.

Founded by Chief Executive Officer and President Anthony Puccio, the family-owned business started in sheet metal. Expanding its services and capabilities over the decades, the California-based manufacturer now specializes in design, development consultation, and fabricating assemblies and components.

Today, Anaheim Precision Manufacturing has grown to a team of 130, operating over 100,000 square feet across five locations in Southern California and providing superlative engineering, milling, assembly, and other services in-house. Operating with the motto ‘Quality and customer service drive our success,’ the business is also well-known for its ability to produce rapid prototypes in just one to three days, depending on the complexity of parts.

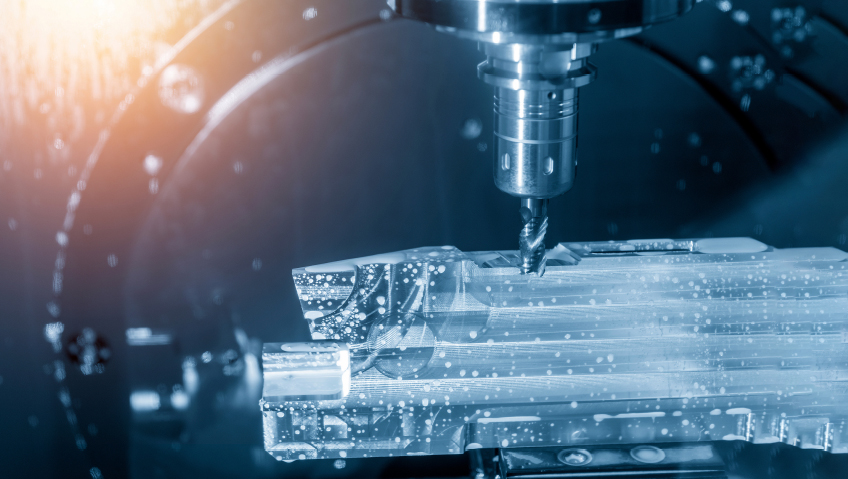

“Our operations range from sheet metal fabrication and assembly to precision turning and grinding, vertical and horizontal machining, and three-, four-, and five-axis,” says Joseph Puccio, Chief Operating Officer. “We also have a design and development arm where we are building and designing aerospace components to spec for our customers.”

One-stop shop

From software to sheet metal and painting to print, APM meets all client needs. The company uses equipment from Haas, Amada, Mitsubishi, Takisawa, and other manufacturing industry giants to perform machining, forming, turning, grinding, welding, deburring, and a host of other services.

Offering CNC machining and CNC turning, precision I.D. and O.D. grinding, mechanical and electro-mechanical assembly, and more, Anaheim Precision Manufacturing is a vertical integrator able to operate as five suppliers instead of one. This includes taking a part from inception – if there’s a design requirement – to building a print job requiring machining, sheet metal, assembly, turning and grinding, and other items like pins, shafts, and bolts and nuts.

From there, APM can perform painting, powder coating, packaging, testing, development, and shipment, all in one solid product. “We’re a one-stop process as far as the manufacturing industry goes,” says Puccio, “and there aren’t many shops out there that are doing all the things that we do.”

Some services are performed through sister companies. This includes painting – through Orange California-based On Line Graphics & Finishing, Inc. Purchased 18 years ago, On Line has a full-blown powder line, eight liquid booths, and the capabilities to produce finishing, printing, placards/nameplaces, and membranes/overlays, and interior labels and control systems for commercial aircraft and treadmill panels.

Another sister company, Riverside California-based D. Mills Grinding and Machining Co., Inc., was established in 2003 and provides CNC machining and CNC OD/ID grinding, sheet metal fabrication, welding, and other services for the aerospace industry.

A focus on quality

As is to be expected, Anaheim Precision Manufacturing adheres to rigorous standards and programs. These include AS9100D and Nadcap.

The latest version of the aerospace industry standard, AS9100D is a quality management system standard centered on the aerospace industry (aviation, space, and defense). Undergoing a major transition, AS9100 was updated to meet the evolving changes of ISO 9001:2015.

According to APM, “abiding by the requirements of the ISO 9001:2015 quality management system demonstrates that Anaheim Precision can consistently provide products that meet customer and applicable statutory requirements thereby meeting or exceeding customer satisfaction.”

Anaheim Precision Manufacturing also adheres to the National Aerospace and Defense Contractors Program, better known simply as Nadcap.

A global cooperative accreditation program for aerospace engineering, defense, and similar industries, Nadcap provides “an industry-managed approach to conformity assessment of ‘special processes’ that brings together technical experts from prime contractors, suppliers, and representatives from government to work together and establish requirements for approval of suppliers using a standardized approach,” according to the organization.

Word gets out

Owing to APM’s many capabilities, exemplary quality standards and certifications, and decades of experience, much of the company’s business comes from repeat customers whose highest expectations have been met. Even with two internal salespeople, a considerable amount of work comes from recommendations.

“We’ve developed a pretty strong reputation as far as delivering quality products on time,” says Puccio. “When we are successful, our customers place an order and we deliver the parts on or before the due date. They never have to be in contact with us; we are pretty much hands-off. You give us your problem, and we solve it for you.”

Previously growing some 25 percent yearly, there’s been something of a slowdown for Anaheim thanks to COVID, particularly in the airline sector, with fewer planes in the air and less of a need for parts. Despite this, APM continues to experience growth in other areas and to introduce new products and services.

Notable in the industry for its seamless services and on-time delivery, APM remains unique in the market. With an inherent ability to understand the design and development side and apply knowledge to production work, APM keeps drawing its clients back with its ability to make complex parts quickly and efficiently.

Even with the pandemic, APM has several expansion plans in place. With about 60 percent of its current business build-to-print and 40 percent of its own product on paper, the company plans to build a print business separately and run it strictly as a design and development firm for products. This will happen once it achieves 60 percent of its own product and 40 per cent build-to-print.

“Our goal as a business is to be a one-stop service provider and issue-free. In other words, hands-off,” says Puccio. “As a business, we are constantly looking not at what our customers are asking us to do today, but what changes are taking place down the road. We’re trying to get ahead of the demands of our clients so that we can meet those demands as soon as they pop up.”