Harcourt Industrial, Inc. boasts a legacy spanning over a century, a culture of innovation and engineering excellence, and a project portfolio that includes battleships, jumbo jets, and rockets.

Headquartered in Madison Heights, Michigan, with operations in the United Kingdom and France, the company provides engineered solutions for precision tooling and assembly work in aerospace and other sectors. In keeping with its heritage of high-profile assignments, it continues to take on massive projects.

“In recent years, we’ve been involved in all the major aerospace programs of record: the Boeing 787 program, the Boeing 777X program and the Joint Strike Fighter (JSF) program—the largest industrial project ever undertaken by man. That’s pretty significant. We’ve been heavily involved in [the JSF] project from early stages,” states Rob Beardmore, President. “We’re seeing a demand from our customers for standardized, off-the-shelf, fast solutions, and we’re uniquely placed to deliver that.”

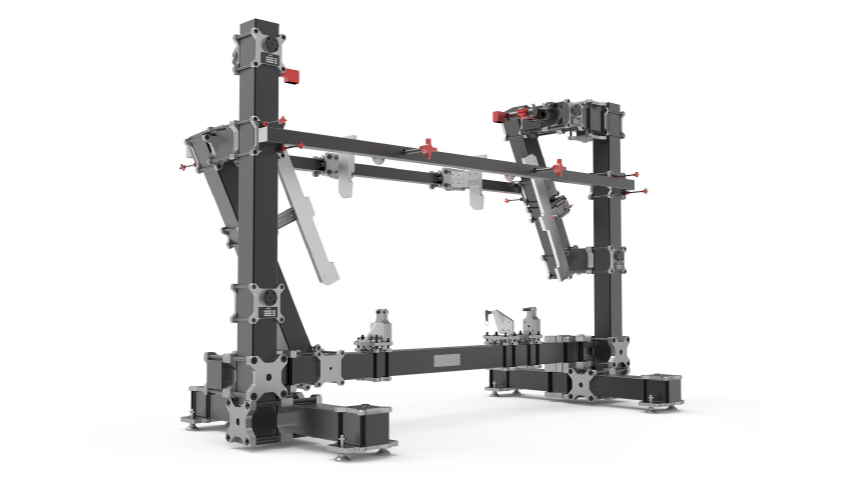

BoxJoint, a tooling product that offers a simple, inexpensive way to build flexible assembly jigs for automotive and aerospace plants, is one of the company’s more popular solutions. Assembly jigs have traditionally been “big, welded structures. They’re very inflexible,” says Rob. “If there are design changes to the product or the customer wants to make some improvements or tweaks, it’s very expensive because they have these big, welded, fixed assembly structures that they have to try and modify and adjust.”

BoxJoint, by contrast, consists of a framework of beams and joints that can be connected without welds as friction keeps the parts together. This distinctive solution offers stability, flexibility and speed. “Our new BoxJoint tooling product allows the customer to put tooling together with bolts and fasteners, so it can be done much more quickly, and it can be changed and reconfigured,” says Rob.

“We like to [compare BoxJoint] to Lego pieces,” adds Dale Beardmore, Project Consultant, and brother of Rob. Just as a building block kit contains standardized blocks that are easy to put together, BoxJoint features “standard, commercial, off-the-shelf parts,” that make jig building simple.

BoxJoint technology can reduce hard tooling costs by up to eighty percent and lead times by fifty percent, according to the company. The system is a boon for another reason: “One of the big trends we’ve seen in the industry over the last five to ten years is that a lot of the talent when it comes to certified welders and jobs like that is slowly disappearing,” notes Dale.

BlackBoard and Captive Products are two other innovative solutions. BlackBoard enables direct-to-part tooling for the composite tool industry. Captive Products are a line of hand knobs, bolts, and pins that “precisely align everything” says Rob, “and keep everything together,” on assembly jigs. Captive tooling eliminates the need for lanyards and the presence of foreign object debris in jigs, he adds.

Harcourt has ISO 9001:2015 certification and strict quality control protocols. The team self-performs “some of the higher-tech manufacturing,” in Madison Heights and subcontracts other work to trusted manufacturing partners, says Rob. It primarily serves the aerospace, automotive and heavy equipment manufacturing markets, including customers such as John Deere and Caterpillar. Of these markets, aerospace dominates, with this sector bringing in an estimated eighty-five percent of revenue.

The company is held in high regard, having won Boeing supplier relations awards in 2014, 2017, 2018, and 2019. This honor is given to firms in the top one percent of Boeing’s supply chain. Boeing works with thousands of suppliers, so winning this award on multiple occasions is “quite an accomplishment,” notes Rob.

Harcourt also works with other aerospace manufacturers such as Lockheed Martin, Spirit AeroSystems, and Northrop Grumman. The company handles civilian and military projects alike and has entered into an agreement with NASA to develop tooling solutions for a rocket.

While Harcourt Industrial was founded in the U.S. in 1999, the firm can trace its lineage to the nineteenth century and a company that was founded in the late 1800s by Scottish shipbuilder, Sir William Beardmore (great-great-uncle of Rob and Dale).

Originally called William Beardmore and Company, this “was the largest employer in Scotland in the First World War. It did defense work, building naval ships for British Royal Navy, then dabbled in aircraft and things like that as well,” says Rob.

William Beardmore and Company helped build a cast steel rudder weighing more than fifty tons for the H.M.S. Hood, a battleship that famously tangled with the Bismarck, a German warship. The company also worked on H.M. Airship R34 (an aircraft like a blimp) that made world headlines for a double-crossing of the Atlantic Ocean in 1919. The company eventually changed its name, but the Beardmore family retains ownership.

Rob believes that Harcourt’s longevity can be attributed to its culture of innovation and engineering excellence and that maintaining this innovation culture is a “top-down” effort. Engineers and designers are encouraged to think creatively and are supplied with cutting-edge tools. The company has embraced two-dimensional and three-dimensional (3D) computer-aided design software, business information modeling programs, 3D product visualization, and augmented reality. It is also moving into robotics—anything that makes design, measurement, and manufacturing more precise.

“[New] industries pop up, then grow very quickly. What you’re seeing is the pace of time to market is getting much shorter. We have a lot of digital tools these days to help with design and engineering. From starting a project to having a finished [product] roll off the line is becoming a much shorter time frame. This is pushing pressure down into the supply chain—customers need tooling much quicker,” states Rob.

While Harcourt prides itself on staying ahead of the curve when it comes to new technology and manufacturing processes, its enduring success can also be attributed to an old-fashioned business ethos. Instead of doing one-off projects then moving on, the firm prefers to form long-term, collaborative relationships with clients.

The company “likes to work closely with our customers—customers like Lockheed Martin, for instance. They have their own research and development team, famous for producing products such as the Blackbird and U-2 [high-altitude military reconnaissance planes]. We work very, very closely with their research team. We’re the tooling people, so they don’t have to worry about the tooling. They can focus on inventing the next greatest aircraft. We’re there to help them with their manufacturing technology,” explains Rob.

Harcourt takes an equally forward-looking approach with its staff. The company has thirty-five employees around the world.

When the COVID virus struck last year, Harcourt was already in an advantageous position “from “a worker safety standpoint,” he says. “We were already paperless and digital. Having our team be able to work remotely was easy for us. We adapted to that very quickly.”

Despite this quick, comprehensive response, it had to withstand an aerospace industry slowdown. The pandemic drastically curtailed airline travel, which reduced demand for new aircraft.

“The airlines took a major hit, and while we don’t work with airlines, it had a trickle-down effect on Boeing and Airbus, the commercial part of our business. Right away, we noticed a sales impact. Thankfully, defense stayed very strong throughout COVID,” says Rob. “That helped keep revenue stable throughout.”

Harcourt is not just about technology and high-level aerospace projects, however; community involvement is very important for the company. “We like to give back to the community. We’ve been heavily involved with some private schools and giving to the American Red Cross. We like to make sure we’re donating to worthy causes, education being a big one,” Rob declares.

Harcourt’s involvement with educational initiatives is particularly relevant given the looming, continent-wide skilled labor shortage. Baby boom-era workers are retiring, and not enough young people are entering the sector to replace them.

“There are a lot of older people in the workforce that are leaving. I think that’s one of the challenges we’re seeing now, with labor shortages. We need to inspire the younger generation to get involved with aerospace and STEM projects. If we can invest or gift into something that’s going to help the industry, we’re all over it,” affirms Rob.

Rob says that, in addition to the skilled labor shortage, which is affecting all manufacturers, the nature of the aerospace industry itself can be taxing for companies such as Harcourt.

“I think the biggest challenge we’re encountering right now is that aerospace is slow. When I mean slow, I mean it takes time to make a decision. Nothing happens quickly in aerospace. It’s very risk-averse, for good reasons,” he states. “In aerospace, you’re playing a long game.”

He envisions a bright future for the firm. “We see some significant growth in front of us. We’re seeing it with our BoxJoint project. Five years from now, we see our product offerings growing substantially and revenue along with it,” says Rob. “I also see us more working as our customer’s [research and development] arm.”