Although it’s a technology-driven company, Septimatech positions people at the heart of its operations. When it comes to customers, employees, or partners, fostering and maintaining close human connections allows the company to empower them through its culture of teamwork and dedication.

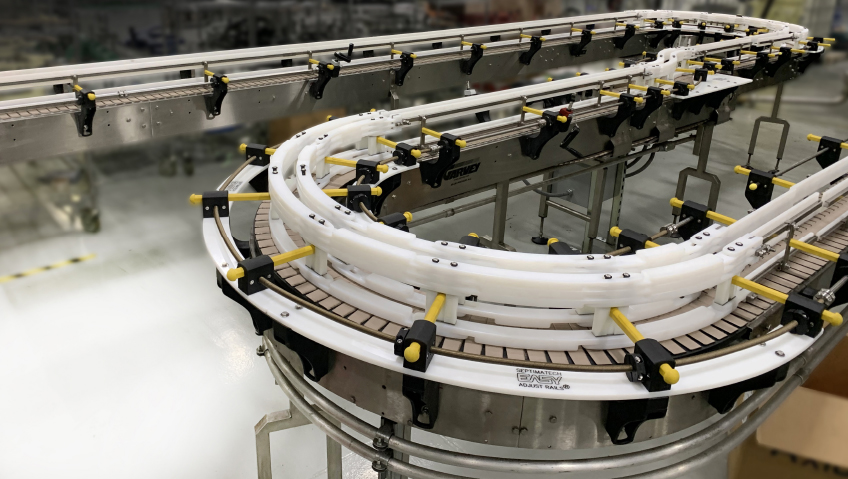

With a team of competent, respected employees and partners, Septimatech collaborates with customers to address changeover difficulties and develop container handling solutions that maximize the performance and profitability of packaging lines while supplying innovative solutions and increasing efficiency on a global scale.

“Septimatech’s name itself, pronounced Sep-TEAM-a-tek, has an emphasis on team, and that represents what we do for our customers makes us stronger together,” says President and CEO Sharron Gilbert. “We do business with Fortune 500 Blue Chip multi-national companies and boutique single site companies, and we have strong partnerships with those customers, with some averaging over 29 years of service since the inception of our company in 1993.”

With a focus on packaging machine and line changeover solutions, the company works with customers to develop new products and solutions based on a collaborative approach that Septimatech has always embraced.

“We help our customers overcome container handling challenges so they receive maximum value and productivity from existing machine assets. Complex container positioning, transfers, geometries, and flimsy, pliable containers are no problem. We have developed solutions for over 2,700 makes and models of packaging machines that consistently deliver better container handling, more efficient changeovers and high value,” says Gilbert. “By having solutions oriented and proactive conversations with our customers, we ensure the supply of the proper product solution that overcomes the challenges they are experiencing.”

Septimatech works across a variety of industries, including the personal care, home and fabric care, beverage, pharmaceutical, and chemical industries, dealing with any kind of product in a glass or plastic container. When customers add a new product to a packaging line or reconfigure their packaging line, container or cap, Septimatech works with the customer to efficiently implement these changes onto their existing machinery. Septimatech’s extensive experience in working on several makes and models of packaging machines results in the customer having a standard and repeatable changeover experience, no matter the equipment make.

Flexibility is key, adds Gilbert, as the industry has a variety of container shapes and sizes, composed of ever-changing application requirements, production demands and resource skill needs.

“As we’re getting more into sustainability and protecting the environment, the packaging industry in general is responding with new product and package innovations,” she says. “That means our customers need greater flexibility in their machines and packaging lines to readily adapt to new types of container materials and geometry.”

Septimatech’s niche is faster, repeatable changeovers, increased throughput and up times, reduced labour costs through time savings, improving container or product handling, and providing innovative changeover and product handling solutions.

“The biggest differentiator is our customer service and supporting our innovative solutions,” says Gilbert. “We stay with our customers every step of the way until they’re up and running. We have a really strong culture that’s customer facing to ensure we achieve superior quality, responsive delivery and strong customer support.”

The company also boasts lower lead times and competitive pricing.

“We always take ownership for the customer experience,” adds COO Quinn Martin. “We’re committed to doing everything right the first time for the customer. Our customers appreciate the fact that… we stick with them to make sure they have a successful product in the end, so they’re able to meet their deliverables and goals within budget and on time.”

As a full-service company, Septimatech designs and manufactures products in-house, enabling a time-sensitive response and quick delivery to meet customers’ needs. It also reduces company lead times while allowing greater collaborative solutions with employees and customers.

“Sometimes we have to make up a prototype or prove out a concept, and with in-house skills here, that’s a leg up for us to quickly respond,” says Martin, adding that Septimatech also relies on its invaluable vendors who provide any services they can’t. “There’s the odd component of the manufacturing process that we do farm out, and we partner with vendors that have the same belief and philosophy that Septimatech does.”

To that end, the company does as much in-house testing as possible to mimic clients’ production environments. “This means utilizing proprietary software and technology, or doing 3D CAD virtual simulations to gain an understanding amongst the customer and ourselves of how the proposed design will perform prior to going to production and shipping,” says Martin.

“Our strength is our people,” he adds. “If it wasn’t for our employees and the culture we have, we wouldn’t be able to deliver everything we’ve mentioned.”

People are the foundation and heart of the company’s success, Gilbert agrees. “Our culture is because of our people and our investment in them and their families. We take care of each other. There’s a lot of respect here.”

The company also strives to promote events and activities with employees to build stronger relationships and promote a safe and trusting place to work. Its low turnover rate is a testament to that resolve.

“We also have a significant investment in training and development each year that gives employees the opportunity to build their skills, to move into other areas,” says Gilbert. “They can work toward programs or courses that would help them transition into new roles.”

Septimatech also promotes a ‘Power of Our People’ reward program open to any employee to share accolades about continuous improvement activities, innovative products or solutions, or serving customers in ways that are above and beyond. “That has a lot of synergies in terms of employees recognizing one another that’s not necessarily coming from the managers,” says Gilbert. “The employees are recognizing each other for their accomplishments. It serves as a great motivator, encourages camaraderie, and increases engagement.”

That increased engagement has been vital throughout the pandemic, with efforts to stay connected when face-to-face meetings have been impossible. When Septimatech was deemed essential to the supply chain, the company decided to “divide and conquer,” setting up an emergency response team to tackle three key business elements, the first being health and wellness of its employees.

“The other element was making sure we had uninterrupted flow of work to ensure our customer orders were shipped on time and that we could keep their facilities running,” says Gilbert.

Gilbert credits the company’s vendors and business advisors with being instrumental in navigating cross-border efforts seamlessly. One example is Cowan Insurance providing guidance on insurance travel coverage and benefit protection.

While COVID has definitely been a challenge for Septimatech, embarking on becoming more digital in 2019 proved to be extremely beneficial, says Martin. “That helped us be prepared for March of 2020 when the pandemic hit. We had a lot of technologies in place so we could reach out and work with our customers or acquire new customers.”

Gilbert agrees, stressing the team had to become more productive and rethink how they did business when their major in-person trade show was cancelled and went virtual instead.

“A lot of work, time, money and investment went into digitizing our customer orders, digitizing how we did business with customers in terms of communication and flow of that information,” she says. “Our website had to have up-to-date information on our product solutions and how we could help them.”

This also led to ensuring information was easily retrievable for people working from home without losing sight of important customer orders through that process.

“It really made us become more proactive to rethink about what could be coming and to be prepared for it,” says Martin. The company focused inward to help overcome adversity for its customers as the pandemic changed the face of almost every industry.

“Consumer habits and the types of products they purchased changed overnight; essential products on grocery shelves were bare. Our role was to help customers increase productivity and capacity so they could get more products produced quickly,” says Gilbert

The supply chain issue continues to be a challenge, including for Septimatech itself trying to obtain materials to make products for customers to meet the ever-growing market demands. Customers are feeling it as well as they experience delays with materials, including bottles and caps, that then impact the project timeline.

Despite the ongoing challenges of the past two years, Septimatech remains dedicated to not only supporting its customers, but its employees as well.

“Families needed flexibility because school children were at home; we quickly adapted and supported our employees in working different hours so they could help their children with schoolwork, an outcome of the pandemic,” says Gilbert. “It’s not back to nine to five, and we’re still supporting families and providing that flex time as needed.”

Septimatech’s customers are also a part of the Septimatech family, which is acknowledged by all employees, adds Martin. “To see the relationships develop with our customers from the initial project through the subsequent projects over the years, and these relationships foster into friendships, is truly a rewarding experience.”