Plastics fabrication company Eimo Technologies serves its North American customers from its base in Vicksburg, Michigan. The business began operations in 1969, led by three entrepreneurs who originally named the venture Triple S Plastics, due to all three having last names that began with the letter S.

The company developed in the plastics industry for decades before merging with Eimo, a Finnish plastics company, in 2000 based on their mutual connection to telecommunications company Nokia. Being the largest two plastics suppliers for Nokia in North America and Europe, respectively, the merger created one global plastic supplier, Eimo Americas.

The new venture lasted until 2002 when Chinese manufacturer Foxconn purchased Eimo to gain access to its clientele and market segment. Eimo General Manager Gary Hallam remembers that it had always been Foxconn’s intention to industrialize its processes in China, as the market was already going that way by the mid-2000s, so the move was initially a beneficial one, but it would ultimately prove to be more of a spanner in the works for the company.

Although telecommunications had been a major part of Eimo’s business, it was only one year (around 2005) later that it had left the sector entirely. New owner Foxconn became much more hands-off. “They already had our customers,” Hallam says. He says that the help of a long-time Kalamazoo-based customer was instrumental to the company’s recovery, allowing Eimo to rebrand in 2006 as an automotive supplier.

In 2007, not long after this rebrand, a new deal was inked with Japanese printing company Nissha, since the Kyoto-based supplier (also, at one time, a supplier for Nokia) was setting out on a globalization effort and wanted a North American facility to show off its products to new customers. Nissha has allowed Eimo to pivot into molding decorative industrial film which is now “a huge part of the business,” according to Hallam, who says that the relationship with Nissha has been “a real win-win for thirteen years now.”

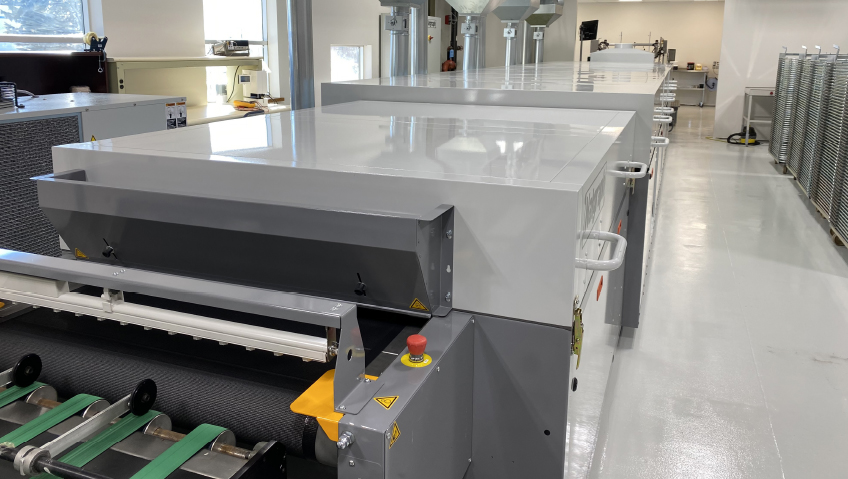

Eimo’s approach to the decorative process is described by Hallam as challenging and versatile, part of its unique identity in the sector. The company involves itself in the decorative processes in plastics with five distinct methods: Ink transfer IMD (in-mold decorating), a cost-effective way of making a decorative part; vac-forming and film-insert molding (FIM), a popular option for the automotive industry; simulforming, a hybrid of the first two processes invented by Nissha; screen printing IML (in-mold label), a process established in 2021 involving transferring to injection molding and a high level of automation for loading/unloading; and TOM (three-dimensional overlay method) processes, involving high-pressure wrapping.

The company has experienced steady, controlled, organic growth over the past twelve years, with sales having increased by 75 percent since 2008 through a combination of continued business from existing customers and the addition of key new relationships. Hallam says that, in the past two years, the company’s work for the appliance market is on a heavy growth track, due in part to processes like ink transfer IMD becoming better known as an economical and cost-effective way for companies to decorate user panel parts found in appliances from washing machines to dishwashers, refrigerators, ice makers, and more. Very few manufacturers, if any, possess the capability and diversity of action that Eimo can offer in its sector.

The way it works with plastics and decorative elements has a positive effect on Eimo’s bottom line, and its internal philosophy has affected other aspects of the business positively. Hallam feels that the company’s workplace culture is very open, with managers involved in the day-to-day business in a very hands-on way. “The goal is to create a culture where people at all levels achieve success, including customers, suppliers, and stakeholders.”

Many employees have had long tenures because of this workplace attitude; Hallam, having spent thirty-seven years in the business, only claims the eighth place on the seniority chart. He admits that social distancing and COVID-19 protocols have made maintaining the company’s family atmosphere more difficult, especially in terms of communication and fraternization among employees. The priority at Eimo is employee safety, so attention continues to be paid to navigating the definition of the term ‘essential business’ and adapting to incoming changes. “We flexed our adaptability muscle,” Hallam recalls, so business has continued as normal for the most part.

He notes that 2021 had a bad start, as Texas suffered an extreme weather event causing pipes to freeze, and material shortage concerns surfaced by mid-year. The price of resin increased throughout the year (a necessary ingredient in the plastics process) to what he refers to as an unprecedented level due to supply and demand challenges, and this pricing continues to put a strain on the industry, leading to a greater degree of customer hesitancy. Hallam credits supply chain manager Jean Hentkowski with ensuring that customer workflow was never interrupted because of these shortages, a huge boon in a challenging time.

Eimo has also been experiencing labor shortages in the past few years, which is a problem across a litany of industries, although it seems to be improving thanks to “the can-do attitude of our people and their willingness to sacrifice,” as Hallam defines it. A lot of headway has been made in the final months of 2021, as sixty-five open positions have fallen to around fifteen to twenty. He identifies these as the dominant issues in current day operations, and these will continue to be dealt with going forward. However, the end-of-year outlook seems positive for Eimo now.

As 2022 is set to begin, Eimo is entering its next phase of growth. Its east plant was finished in 2015 but that has since become full. Plans were put into motion in 2021 for expansion, and ground was broken in early October to add 32,000 square feet, up to fifteen additional injection molding machines, and 25 percent further capacity.

Hallam has observed that there are continuing supply chain and logistics problems on a global scale, with many of the company’s customers experiencing many unplanned non-production days due to semiconductor issues or because of lockdown measures in Asian countries, leaving related businesses unable to produce and ship.

When it comes to these problems, Hallam cites an inspirational quote that best defines the company’s style: “We can’t direct the wind, but we can adjust the sails.” Eimo constantly monitors situations and adapts to them, only worrying about what can be controlled within a challenging environment. Its workers still enjoy coming into work and meeting challenges and taking on difficulties together as a team.

Eimo has expanded the market in the past six years and has evolved into one of the world’s leading injection molding manufacturers. The company will look to continue cornering that market segment and bring more of its projects in-house, growing in a controlled fashion both locally and organically.