Why is automation, the process of introducing robotics into industry and making processes more machine-driven, so often spoken of in anxious tones?

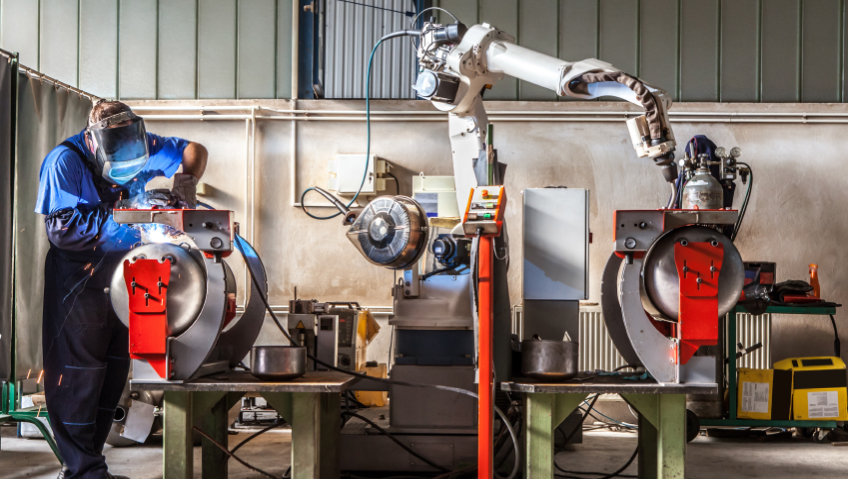

It’s clear that many, both insiders and onlookers, seem to fear that the ongoing implementation of robotics and machines into factories, assembly lines, and other manufacturing sites will mean the end of human-based labour and a sure sign of economic downfall. What is closer to the truth is that humans will likely continue to have a presence in all these automation-friendly sectors going forward – but it will more likely be in a partnership with machines rather than a tool-user relationship.

This emerging idea of human-robot collaboration is one that seems to promote a more positive and lasting link between an age-old workforce and its new-age solutions, as well as favourable economic and industrial returns.

The process of automation is hardly a new phenomenon, as some of the earliest examples of its role in the workplace date back to the 1960s with simple machines providing support for tasks like picking or spot welding.

Robotics gradually grew more advanced as the decades continued and adapted to support and enhance human roles in manufacturing settings, a trend that will certainly continue as more highly developed automation is developed and the buy-in for robotics becomes more accessible.

In a piece for the World Economic Forum, CEO and co-founder of Veo Robotics Patrick Sobalvarro describes a collaborative environment for humans and robots that is rapidly being adapted to as calls for changes in the market (i.e. faster production, higher quality standards) are coming about too quickly for humans alone to be able to respond to. On the other hand, modern robots and robotic tools operate too quickly and with workloads too dangerous to be effectively implemented near humans, while also lacking the intricacies and frameworks of the human mind that make modern-day innovation and education possible.

To truly succeed, according to Sobalvarro, workplaces of the future must “combine the strength, precision, and speed of industrial robots with the ingenuity, judgment, and dexterity of human workers.” A workplace that implements this kind of cooperation can see its processes speed up and take on greater efficiency, as well as benefitting from lowered costs and greater production diversification.

Current-day robotics operate in a framework that is referred to as Industry 4.0 (or the Fourth Industrial Revolution), essentially meaning that the technology is frequently interlaced and in concert with other “smart” technologies that aim to benefit humans and increase productivity. This new reality is leading to the possibility of a new hub for human-robot collaboration: “smart factories,” a development further expanded on in a paper, Trends in Smart Manufacturing: Role of Humans and Industrial Robots in Smart Factories, by Linn. D Evjemo, Tone Gjerstad, Esten I. Grøtli and Gabor Sziebig.

The researchers found that these factories will be able to operate with both high levels of technical efficiency and human-like elasticity and ingenuity, ideally combining these traits into a synergy of minimized costs and overall labour requirements.

“By connecting the robot even closer to the human, in terms of direct collaboration or task sharing within the same working area, there is important potential for a strong synergy between the robots’ and the humans’ capability; thus, a very productive, user-friendly, however, rapidly changeable, system,” say the authors.

This idea is not even a pipe dream at this point but a slowly dawning reality. Jonathan Wilkins, in writing for Reliable Plant, reports that human-robot collaboration is closer than ever thanks to the development and implementation of collaborative robots, or “cobots.” Cobots are made for just this type of workplace partnership, designed specifically to manage physical strain and endure repetitive tasks and so allow human partners to complete work better suited to the more complex and intuitive human brain.

These robots are also designed with surfaces that are less angular and are softer to the touch to reduce potential injuries to humans, along with sensors to detect nearby objects and avoid collision. Furthermore, regulations such as ISO 10219-2:2011 are currently at work to manage the introduction of these robots into human-centric environments to promote safety. Cobots are a budding aspect of the robotics industry as many businesses shape up to meet this new demand. Developments in the field could lead to greater sophistication down the road.

This is not to suggest that changes to industries which invite automation will leave humans unaffected. Although one goal of human-robot collaboration is to promote humans to less physically arduous and more creatively fulfilling roles, the fact is that automation is seen by some employers as an acceptable way to deemphasize human involvement altogether in manufacturing settings.

In an article for Time Magazine, Alana Semuels reports that “job loss via automation threatens [people of color] disproportionately as the labour being replaced by robotics largely affects Black and Latinx workers,” with automation potentially displacing 132,000 Black workers in the U.S. by 2030. Semuels also references studies that indicate job loss in the hundreds of thousands in factories in the last few decades and that robots could replace millions more workers in manufacturing spaces in the next several years.

A paper on the effect of robotics on labour markets by MIT professor Daron Acemoglu and Boston University professor Pascual Restrepo has found that for every machine per 1000 workers in the United States, wages have decreased by 0.42 percent. Around 400,000 jobs have been lost due to displacement.

Nevertheless, referring to the paper by Evjemo, Gjerstad, Grøtli, and Sziebig, the ideal that is human-robot collaboration is not yet ready for widespread adoption, especially when the sensor technology needed to ensure worker safety is still not at a level to effectively and predictably account for the less-than-clockwork behaviour of humans.

As with any new idea or movement, there are still more than a few kinks to work out, which many automation manufacturers and robotics experts are not blind to; however, the more technophobic cries of workers fearing being wholly replaced by machines may not be as merited as once thought.

Writing for Forbes, Ron Harbour and Steve Scemama note that robotics are still very much dependent on human input, especially when required to customize products (a task that still escapes today’s modern systems) or to maintain the machines at peak efficiency. The two de-emphasize the idea that robots will usurp humans in manufacturing altogether, adding that if this were even to be done at all, much would be lost in human knowledge that would not justify the still-considerable expense of automation.

In his paper with Restrepo, MIT professor Daron Acemoglu elaborates the current tension: “Overall, robots have a mixed effect: replacing jobs that relatively high-wage manufacturing employees used to perform, while also making firms more efficient and more productive.”

So, in summary, collaboration in the workspace between humans and robots presents many fascinating questions and exciting possibilities for genuine evolution in today’s manufacturing facilities.

As the tools, and as we as people, become more sophisticated in the effort to ease the toll taken on human bodies for the sake of growth and industry, it’s only with a guiding hand, and an imaginative spark from humans, that these more elegant robotic solutions can achieve anything beyond rudimentary goals in the workplace. And it’s clear that the positions of both workforces are best suited side-by-side in the facility of tomorrow.