American robotics systems manufacturer Alliance Automation offers automation solutions to a multitude of sectors. The company began operations in August 2008 when President and CEO Doug Wenninger, wanting to take advantage of an opportunity he saw within the market to branch out and offer automation to underserved industries, left a Sales Manager position at another automation company to form his own.

After purchasing a small building in Delphos, Ohio, the company began its initial year with only six employees and in the middle of the infamous 2008 recession, which devastated the economy and the automotive industry, a frequent customer for automated solutions. Thankfully, by December 2008, the company had grown to over thirty employees and has been evolving and expanding ever since.

The nascent company’s first big opportunity came in its initial year from CHEP, a global company concerned with moving goods and the largest wooden pallet company in the world. Wenninger explains how wooden pallets, as a business, are essentially recession-proof. “Everyone needs goods and [those goods] are shipped on pallets, which became a major part of our business.”

Wenninger remembers how, upon first entering the CHEP facility, he felt as though he was walking into the Stone Age. By 2008, CHEP used mostly basic manual equipment, with the plant producing 130,000 to 160,000 pallets a week with low automation.

Alliance began work on automating CHEP’s processes and continued to grow alongside it while pushing toward better and more efficient solutions for the pallet industry overall, now a large part of Alliance’s business.

In 2014, Wenninger and the Alliance team put time into producing a study on automation trends in Europe, discovering that the continent has been fifteen and twenty years ahead of the United States since the end of World War II when a shortage in available labor necessitated developing automation solutions. Using this information, as well as self-driven reports from the lumber industry, Alliance sought to improve the processes involved in wooden pallets, especially the dangerous and tedious process of pallet recycling. A 2012 OSHA study determined that the number one cause of industrial amputations came from manual pallet dismantlers.

The initial goal of automation for the pallet industry, as Wenninger recalls, was to offer safer and greener solutions while keeping employees, imbuing them with advanced skillsets to oversee automation instead of being pushed out by it. This objective led to the development of robotics systems for pallet businesses, the first installed in 2017 and now numbering about thirty within the market.

Along with these automated systems, Alliance introduced what Wenninger refers to as the urban sawmill line, the process of arranging lumber on a conveyor, running it through a vision system to determine length, width, and thickness, then sorting through size. This process has nearly doubled pallet production while using fewer people, helping to solve the ongoing labor problem and bring more automation opportunities into the market.

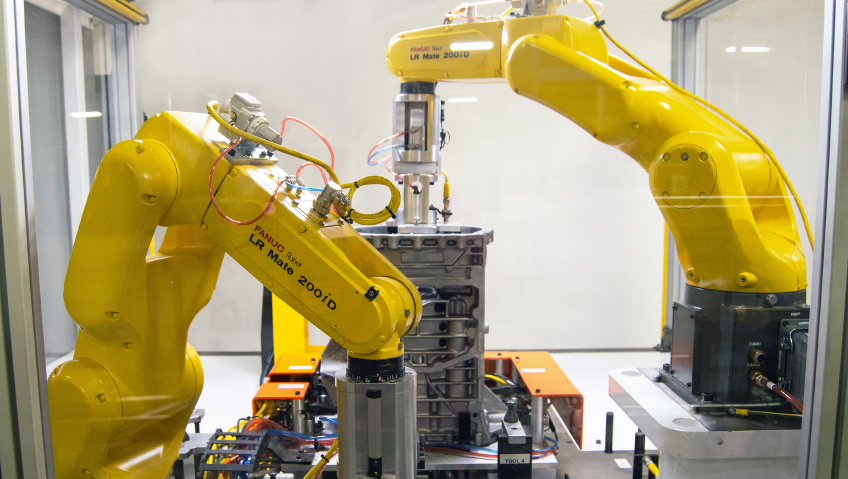

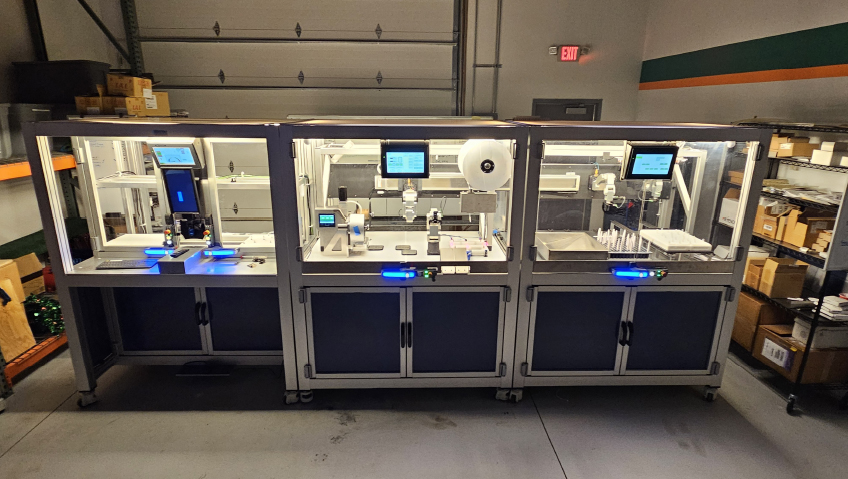

Beyond its work with pallets, Alliance continues to work across many business sectors as its work in the former provides proof of the company’s capabilities. Offering custom automation solutions and engineered systems, the company brings its in-house engineering skills to bear in the areas of Battery Assembly, Palletizing, and Assembly. “If you have an automation problem, we can solve it,” says Wenninger.

It is not just a dependable work ethic and favorable solutions that have kept the business a go-to name in automation. Alliance makes a point to be as open and transparent as possible with its customers to assess operations while finding the biggest automation needs through an in-person auditing process.

Wenninger stresses that Alliance is always looking for a mutually advantageous situation for it and its clients. “If we can’t solve a problem, we won’t sell [clients] on a solution… We all lose if we don’t all win.” Through this approach, customers gain knowledge of Alliance’s costs, profits, and margins, further allowing a greater understanding of their place as a valued partner. While customers are the experts at building a product, Alliance is an expert at manufacturing solutions to build it effectively and quickly. As Wenninger summarizes, Alliance does not want customers; it wants partners.

The past year and a half has been one fraught with change and challenge, but Alliance has come through to even greater success. At the beginning of the pandemic in 2020, the company learned slowly what its new parameters and limitations would be to keep workers and customers safe. It was considered an essential business due to its work in consumer and food industries as well as shipping and transport.

Wenninger and company officials encouraged work-from-home for all who could safely do so, and although a few COVID cases were reported among employees, the company experienced no detriments other than some delays. In fact, not only was the company able to keep its doors open but it experienced its highest revenue and profit year in 2020.

While the company has been successful in the face of global challenges, a lasting effect of the pandemic observed by Wenninger is that every business is having trouble finding people to work. This has left a massive opportunity for automation across all sectors and is leading to a boom within the industry. However, these labor shortage problems have, in turn, affected Alliance and other automation companies, and it has become hard to find skilled engineers and trade workers to hire.

Alliance counters this by supporting various aspects of science, technology, education, mathematics (STEM) education, through coaching and funding local robotics clubs, establishing a scholarship fund for engineering students, and hiring high school interns to educate and excite them about the industry.

Major supply chain issues have also occurred, causing automation businesses to double the expected time on some projects due to ongoing problems in securing materials. The industry in 2021 has seen as many opportunities as obstacles but as countless business sectors have now moved into what has been called the Fourth Industrial Revolution, centered on robotics and automation, the sky seems to be the limit for growth.

Alliance Automation is still young after only thirteen years in operation, so Wenninger expects it to continue growing at a rapid pace. Its first corporate building was 40,000 square feet, which it quickly outgrew. Now, the company is bursting at the seams even with more than double that amount of space. Wenninger began pursuing plans to design and build its own facility in 2019, looking for something to portray Alliance as a technical and forward-thinking company with an emphasis on work being fun.

After successful meetings with designers, the building should be completed in late Q1 2022. The new facility will contain a classroom to aid in Alliance’s recruitment efforts and will offer accredited classes for high school and college students that will count towards class credit and hopefully attract young workers to the automation industry.

Wenninger also hints that a lot of investment has been made internally into the research and development of new and exciting products to be released next year. The company has adopted a ‘forest-to-factory’ approach to its continued work in the pallet sector, as it seeks to marry it with robotics. “All the equipment built for the pallet industry is built for recycling, repair, sorting, teardown, and wood recovery of used pallets,” Wenninger explains. “We will be pushing projects that march closer to the forest… Whether forest or factory, Alliance will be there.”