In markets where speed and quality are of the essence, MiQ Partners provides intelligent fabrication, automation, and assembly technology to some of the world’s largest manufacturers in the medical device, aerospace, and consumables fabrication sectors.

MiQ Partners is the go-to team for next-generation ideas and manufacturing processes backed by complex engineering, automation technology, and assistance in obtaining approval from the Food and Drug Administration. Understanding its customers’ need for speed, the company has technology and human talent that can design solutions, implement automation systems, and deliver machines more quickly than ever. And with the remote technology available through AI and the IoT, MiQ provides opportunities for clients to monitor the progress and processes of their projects remotely and in real time. All operations take place from a 100,000-square-foot facility in West Chester, Ohio, just north of Cincinnati, or the company headquarters, the 40,000 square foot campus in Carlsbad, CA.

Because of the “intelligent” approach to industrial automation for manufacturing across industries which involves organizing diverse, cross-functional engineering teams to brainstorm solutions to complex challenges, MiQ has been able to reduce cycle times from clients’ processes from minutes to seconds, and lead times by weeks, not just days. Automation is the lifeblood for the medical device industry, and MiQ is the lifeline to help many medical device companies produce rapidly, and accurately, getting products to patients when needed most.

Throughout its more than 70-year history, MiQ Partners has taken client projects from problem solving and design concept to machine build and installation with comprehensive support and customer care throughout. During a time in which pandemic-related health and production concerns disrupt processes, the company’s machines are allowing brands in all industries to continue moving forward and to remain competitive and profitable despite market uncertainties.

Enable Injections, a company developing innovative drug delivery systems, has benefited from MiQ’s ability to come up with solutions that minimize time while maintaining effectiveness of the quality management system. Following is a brief example.

The challenge:

Enable Injections needed to transition from a pilot line for assembly, test, and inspection of an on-body delivery system to a semi-auto/fully auto line with over 40 discrete parts and complex geometries.

The solution:

MIQ Partners’ engineering team learned the product design, developed strategies with the customer to overcome many obstacles and developed semi-automated/fully automated cells into an assembly, inline inspection, and test production line.

The outcomes:

MiQ developed over 50 custom designed machines to make up several production lines, increasing production capability by 10 times while improving overall quality.

“We partnered with MiQ early on in our scale up project while the enFuse® technology was still in development, says Brian Costigan, Associate Director, Manufacturing Engineering for Enable Injections. “MiQ proceeded to help us with automation concept design and then timely build of our automation equipment. They were collaborative partners throughout the entire process to ensure that as our product went through design changes the automation equipment was updated to accommodate.”

Automation is increasingly becoming the key difference between success and failure for companies across industries as it enables companies to maintain uptime despite labor issues, reduce failure rates and mistakes, and keep production lines running 24/7 as needed.

If someone on the manufacturing line becomes ill due to COVID-19, assembly lines will be shut down and vital medical testing equipment and other devices cannot be manufactured, having a direct impact on lives. “Automation is definitely a big solution for that,” says Chief Executive Officer Olaf Tessarzyk, whose military background has allowed him to lead the team through some demanding times over the past year since joining the company in October 2020.

Tessarzyk points out that adaptability contributed to the company’s quick response to the increased demand for automation systems and machinery in the field of life sciences. Many of these machines manufacture diagnostic test kits, making MiQ Partners an integral part of dealing with the global health crisis.

“We had to [constantly] look at how to mitigate risk during COVID times and how to keep the doors open. It required a lot of communication,” he says. Thanks to the team’s Herculean efforts, MiQ Partners made an impressive success during this difficult period in its history. “Everybody was very proud that we helped impact people’s lives in a positive way,” he adds.

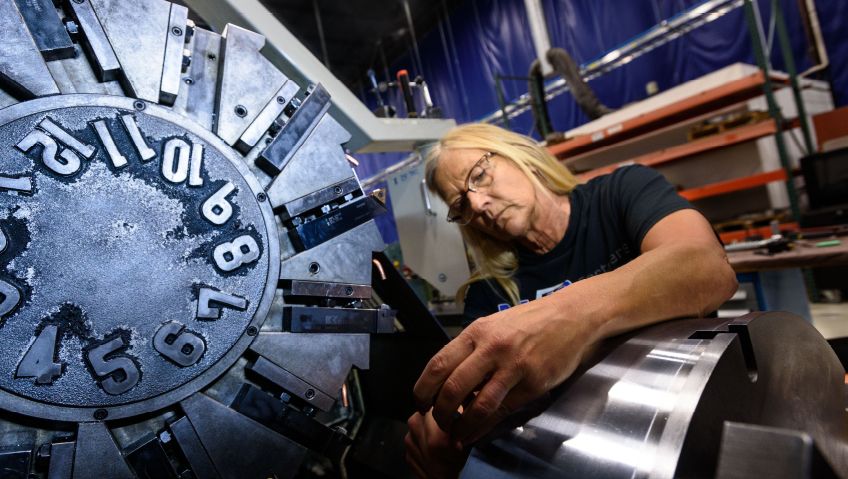

An interesting trait of many of the roughly 110 staff is that several of them owned businesses before joining. This infuses MiQ Partners with an exceptionally pioneering, hardworking spirit, and the staff is dedicated to achieving successful outcomes. It also gives the firm a leading edge when developing entire systems that adhere to stringent rules set by governing bodies such as the International Organization for Standardization or federal government, depending on clients’ exact needs. MiQ Partners maintains certification for ISO 13485:2016, A9100D, and NADCAP approval.

The company’s approach to defining a client’s machinery requirements starts with studying the manufacturing processes and desired result. This is followed by studying the prototype and its mass manufacturing requirements. Once the machines are designed, measures to meet acceptance criteria are incorporated into the final renderings before fabrication starts. Other services cover all-inclusive mechanical support for a machine’s lifespan, including remote diagnostics and on-site repairs.

Being able to identify and solve client problems and needs is a big part of what sets the company apart from its competitors. Because of in-depth vertical expertise for the industries MiQ serves most, the team is able to bring highly relevant insights for innovative solutions that are hard to find elsewhere. Tessarzyk’ s extensive experience as a client of automation companies has been garnered throughout his career, so he knows what clients want and how to be better than the run-of-the-mill firm of this kind in the market.

“In addition to building automation, we have a very big machine shop that provides spare parts and services to customers. [Always] having parts in stock alleviates a big pain for customers,” he says. This enables the company to supply spare parts immediately instead of keeping customers waiting for weeks or months in some cases.

Even during market uncertainties and challenging times for the manufacturing industry in general, MiQ has not just maintained its stability; it has actually grown. Recently, the company moved its headquarters to Carlsbad, California, expanding its facility by 40,000 square feet to better serve the many life sciences, medical device, and aerospace companies in this area.

Tessarzyk exhibits a deep understanding of and empathy for people, which has helped the company maintain a consistent supply of talent. He learned the importance of leadership and teamwork as a leader in the German Military during the early years of his prolific career, which earned him membership in the prestigious Young Presidents Organization. He currently is a volunteer Search and Rescue Pilot for Orange County, CA and Chief Flight Instructor for another unit in his spare time, all of which continues to inform his leadership style.

“It is important to keep focused on the purpose of the company and to keep the people at the center of that focus,” he says. “One thing that you learn in the military, and especially in aviation, is that you can only be successful if you have people you can trust. It helps when you have a common goal.”

He also points out that, to achieve success, knowing how to motivate people is of the essence. Making fast yet sound decisions is also crucial to working under pressure and protecting his staff and customers. “It helps to keep your eye on a common goal. I think it is something that companies miss sometimes,” he says.

Tessarzyk says that finding labor has become a challenge across the country in recent years, making robotics a welcome go-to for producing necessities, especially in the medical field. With automated processes executed through robotics with machine vision and remote access, production processes can continue 24/7, keeping projects on schedule, and distribution pipelines full.

Using robotics also means that there are fewer errors, and this is especially needed in medical goods manufacturing. In this field, the mistakes resulting from manual labor can translate into a defect rate that is much higher than the average of around five per one million units that is seen in automation. Additionally, mistakes delay the distribution of needed medical devices and supplies to consumers which adds to other social issues that go far beyond manufacturing efficiencies.

Following the tremendous contribution MiQ Partners has made to the world of automation in North America and beyond, Tessarzyk forecasts matching the company’s status in the Midwest and becoming the dominant supplier of automation to the life sciences market on the West Coast.