For North-American, Asian and European Tier 2 and 3 original equipment manufacturers (OEMs) and other innovative companies looking to bring projects to life with leading-edge electronic manufacturing services (EMS) and custom material solutions (CMS), Vexos provides purpose-specific solutions, first-rate customer care, and a vast global reach that renders the company unique in its powerful capabilities.

Driven by quality and innovation, Vexos is nimble and responsive to clients’ needs. “The customer wants to be heard,” Senior Vice President of Global Business Development, Cyril Fernandes, says. “Having the right fit for the customer is key.”

The Vexos service portfolio includes flexible, low-to-medium-volume electronic manufacturing services that effortlessly merge with its customers’ existing supply chain needs and specifications. From its headquarters in New York, the company’s international presence enables easy collaboration between its manufacturing facilities in Ohio, Ontario, Vietnam, and China. Vexos also offers warehousing facilities in the U.S. and Hong Kong.

The company is the result of a 2014 merger created by the new owner, Centre Lane Partners, LLC, between STACI Corporation of LaGrange, Ohio and EPM Global Services of Markham, Ontario. According to Fernandes, both these firms were well established with legacies spanning more than 25 years. Together, the two leaders offer over half a century of proficiency in electronic manufacturing and custom material solutions.

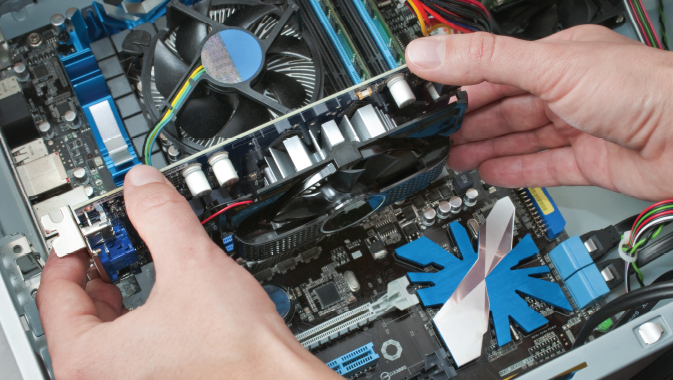

Vexos is deeply involved with provisioning highly complex, fine-pitch electronics assemblies, electromechanical assemblies, full turnkey solutions and custom mechanical parts, making its selection of services truly impressive. In addition to EMS services, the company’s custom materials solutions also include a large selection of specialty items like complex cable assemblies, silicone products like keypads, switches, and other components, sheet metal stamping, die casting, aluminum components, injection moulded plastics and bespoke finishes, a range of heat sinks that regulate the temperature inside electronic devices, several different printed circuit board options, and semiconductors.

The Vexos value engineering team makes clients’ electronic product goals a reality through a thorough process that extends right through the prototype phase to industrialization, followed by production, logistics and product launch. Design for excellence (DFX) engineering methods are applied throughout the design phase focusing on material, fabrication, assembly, manufacturing, cost, test and reliability. The final design is followed by carefully developed, leading-edge manufacturing processes. Other services include assembling printed circuit boards, system integrations, and advanced rapid prototyping used to create three-dimensional (3D) models of any physical element like assemblies or parts. The company also offers electronic testing and repair services.

Vexos also now offers design for supply chain intelligence through component engineering and predictive technology tools that provide proactive solutions to its customers, giving them feedback such as bill-of-material (BOM), health assessment, and risk management analyses. In this way, it drives new technology, quality and cost reduction for current and new customers. Cost control is maintained throughout each process, as are its return materials authorization (RMA) and repair depot services.

With such solid expertise, it comes as no surprise that the Vexos range of EMS and CMS services are tremendously sought after, benefitting the automotive, medical, internet of things (IoT), industrial and commercial, communications, aviation, defense and space industries, amongst others. Vice President of Engineering, Brian Morrison, notes that Vexos provides new product introduction services to highly complex, technical companies, including rapid prototyping for silicon support solutions. “We work very closely with their engineering teams throughout their product development,” he says.

Morrison also notes that choosing the right component partners is extremely important to Vexos business and its customers. One such partner, Freedom, is an independent distributor founded in 1999 as a full-service, global supply chain partner covering the Americas, Europe, and Asia. Freedom supports all Vexos’ facilities with competitive pricing, quick turn-around quotes, quality products and excellent service day and night. The Vexos account is overseen by Global President of Sales, John McKay, who is extremely responsive to its needs. Components are secured from reputable OEMs and franchised distributors as first options. Components from other sources are fully tested and inspected before shipping.

Here, component quality is key as Vexos helps its clients design and manufacture their products with alternate components that enable them to be at least a year ahead of the market. “[We offer] complete turnkey design support and functional development that we’ve developed from the ground up,” Morrison says. He adds that Vexos has been able to provide this at a lower cost than its competitors. “[They also get] the leading edge that other tiers wouldn’t have been able to offer them,” he says.

The company is always receptive to new technologies and new ideas that its customers may provide. “It’s to their benefit to share those ideas and ways of doing things to shorten our time to market,” Morrison says. “We pass those savings onto them.” The company is as capable of serving long-time customers as it is of assisting young companies at the start of their business journeys. Vexos typically provides operators with fantastic value in terms of planning and keeping costs down, allowing them to gain as much market share early on as possible.

“There are a lot of good $100-million to $250-million organizations that require the same level of service, support, and global footprint as larger [Tier 1] organizations. Our structures and global footprint are unique to our size,” says Fernandes. As a result, Vexos provides the same level of service and value-added services as a company serving Tier 1 operators.

Vexos is no stranger to collaborating with leading third-party contributors to create unsurpassed results for clients. This has helped the company build a reputation for creating more than electronics; it also builds long-term relationships. “We focus on getting the right people with the right expertise to create the right solutions,” says Morrison. With dedicated business developers in both North America and Europe, the company has positioned itself to provide customers with the finest supply chain solutions available in the markets today.

As a service and custom parts supplier, the company prides itself on achieving several industry firsts. Some of these feats include significantly improving customers’ automation processes. One way of doing this is by introducing automated material handling that allows incoming materials to be collected rapidly, reducing standard operation time from eight hours to less than thirty minutes.

The Vexos team is also known for getting competitors to collaborate. It once convinced two international giants, to combine their software development teams. The aim was to create a single language that would enable uniform systems communication across multiple platforms like material systems, surface-mount technology (SMT) lines, and financial and transactional systems. “This level of automation technology is unheard of for an EMS provider like us. Our financial and transactional systems all talk as one which provides us an unparalleled leading edge,” says Morrison.

Vexos looked at six possible partners before selecting Juki as its partner of choice to automate its manual warehousing and storage systems. This resulted in automated transaction, material tracking, and pick and put away automation and more, plus the best return on investment (ROI) of all the firms it had considered for the project. The project included its current intelligent storage solution system alongside six Juki ISM3600 towers and one Juki ISM500 tower. With improved efficiency, uptime is greatly extended while manual errors are eliminated.

One of the company’s greatest achievements was sealed and signed in the wake of the COVID-19 crisis, when Vexos was called on to develop technology that would drive the Mechanical Ventilator Milano (MVM) machines that aid patient breathing. The machines will be distributed nationally and internationally by Vexos.

The MVM initiative was ultimately borne of the Global Argon Dark Matter Collaboration (GADM), an international scientific collaboration exploring the subject of dark matter at prestigious institutions such as Istituto Nazionale di Fisica Nucleare’s Gran Sasso Laboratory in Italy and SNOLAB in Canada. An experienced group of researchers, engineers, and physicists worked closely with the Vexos team to perfect a piece of ventilation equipment that fits specifications. Thorough testing, solid supply chain capacity, and speed were of the essence and were the reasons Vexos was awarded the project. Working around the clock, the international team managed to secure emergency-use authorization from the Food and Drug Administration (FDA) just six weeks after the project was launched.

A reputation for such excellence means that quality assurance is one of the company’s greatest focuses. To ensure that customers get only the best technology and service, Vexos holds various certifications by the International Standards Organization (ISO), such as ISO 9001 and the medical ISO 13485, held by all its sites. Both its Asian facilities are certified to ISO 14001, as well as the International Automotive Task Force certification, IATF-16949, and the Korea Good Manufacturing Process (KGMP). Its Canadian facility is certified under the Controlled Goods Program (CGP). Vexos also adheres to Food and Drug Administration (FDA) standards at its LaGrange facility, as well as those set by International Traffic in Arms Regulations (ITAR). All sites are Reduction of Hazardous Substances (RoHS), and non-RoHS compliant.

Where there is excellence, success follows and as a result, the team has been honoured with numerous awards over the years. Last year, Vexos received Dover Corporation’s 2019 excellent supplier award. It also received Circuits Assembly magazine’s 2019 service excellence awards for manufacturing quality and technology. Circuits Assembly gives service excellence awards (SEAs) for electronics manufacturing services (EMS) providers. “I can draw a direct link between the awards we received in 2019 and the work we were awarded with the MVM ventilator in 2020,” says Morrison.

But Vexos is not all about hard work. It is also about its family of around 750 employees, making open communication and respect two of its greatest tools to create a healthy team spirit. The company also contributes its fair share of financial aid to several great causes. Some of these include the Heart and Stroke Foundation in Canada, annual food drives, and many more. “At Vexos we work on one golden rule: treat others as you want to be treated. How we treat [others] is a reflection of how we work internally,” says Fernandes.

This is a team that is always searching for new technology – a strength that will help it transcend economically tough times and take it to new heights in the future. Its contribution to developing technology to support the Mechanical Ventilator Milano has already proven that fact as Vexos continues to build on its excellent track record. We are excited to see what complex new technologies this industry visionary will come up with next.