Fives North American Combustion, Inc., of Cleveland, Ohio, provides services and solutions for the thermal process industry. The company matches its products with comprehensive customer support.

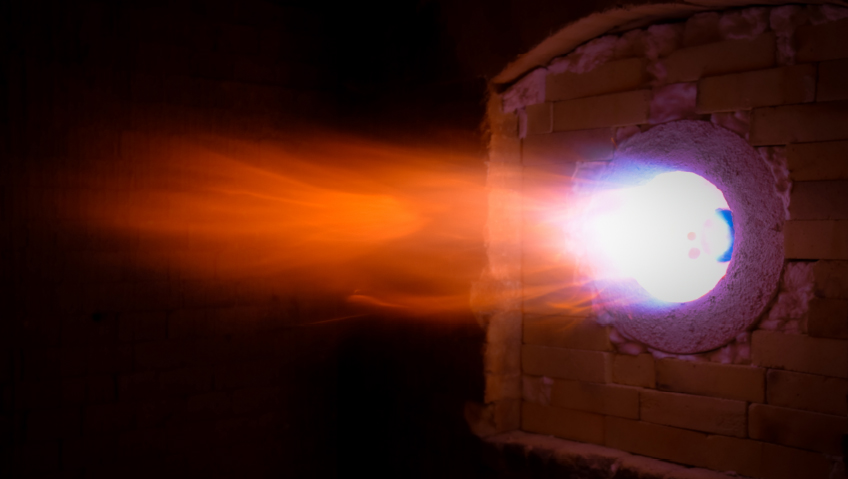

“Any industrial process which needs heat – which is almost all of them – we play a role in,” explains Manager of Business Development Justin Dzik.

Founded over a century ago, Fives North American Combustion is now facing one of its toughest challenges ever in the form of COVID-19. The firm has instituted wide-reaching health and safety measures to ensure that operations run as smoothly as possible during the pandemic.

“Right now, things are pretty much business as usual for us, just with more precautions and safety measures to make sure our employees and customers are safe,” states Marketing Specialist Elyse Schodowski.

Part of an industrial engineering group based in France called Fives (the name is pronounced ‘Feeves’), the company provides boiler equipment for the energy sector, hot gas generators for the chemical sector, forging and heat treat gear for metals (including aluminum, copper, and steel), and rotary kiln and drying equipment for cement and minerals, among other markets.

It sells burners, hot gas generators and process controls, and accessories such as pressure gauges, flexible pipe nipples, oil pumps, manometers, metering flanges, temperature, and pressure transmitters. While Dzik says that Fives has “a lot of standard products that people will buy [and] a lot of accessories,” the company’s true specialty lies in developing customized solutions for clients. These custom-built combustion systems might involve various Fives products and processes.

It also offers thorough customer support, in the form of maintenance services, installation, training, on-site process analysis, technical help, and spare parts. “We have a fully staffed service department. We send field service engineers out to tune our products, to service them if something goes down. We have a customer service department located in Cleveland, but then we also have customer service representatives at each of the sales offices. They can answer a call, help people with a problem, get parts,” says Dzik.

While the Ohio state government has issued stay-at-home orders to stop the spread of COVID-19, Fives has been “deemed an essential business to the supply chain of important industries, so we actually are still open. Our shop is still open, and all the office workers are at home. The impact has been minimal, but we will be impacted if our customers have to shut down,” he says.

“We’ve done a lot to protect our employees. Pretty much everybody from our office is telecommuting. We’ve increased sanitation and cleaning efforts in our facilities. We’ve limited outside visitation. Our shipping and delivery timeframes at the moment are pretty normal, but this could change because the way supply chains are being affected,” adds Schodowski.

Fives’ American branch was founded in Cleveland in 1917 as the North American Manufacturing Company. It was initially focused on repair work for electric motors and later moved into the design and manufacture of industrial combustion equipment. In 2008, the company became a subsidiary of French-based giant Fives and underwent a name change to Fives North American Combustion, Inc.

The company is currently part of Fives Group’s combustion process business line, along with Fives Pillard of France and Fives I.T.A.S. of Italy. Fives North American Combustion sometimes works with others in the Fives Group network on projects.

Asked to name the ‘secret’ behind Fives North American’s impressive longevity, Dzik lists two things. “First, we’ve never stopped innovating. At one time, we were putting out ten to twenty patents a year, constantly pushing the envelope, especially during the 1970s when new emissions regulations were coming in. We were at the forefront of staying ahead of that.”

Indeed, innovation has been present from its earliest days. One of the company’s first big products was a gas-electric blowtorch, which was only recently retired from the Fives catalogue. The firm introduced the industry’s first dual-fuel burner in 1929 and launched its famous Tempest burner in the late 1960s. The Tempest “is our most popular burner and still an industry leader for high-velocity burners today,” notes Dzik.

The second component of the company’s success is the durability of its products. “We make very robust products. If you see ours compared to our competitors, we use heavy cast iron. I have seen a Tempest burner from 1968 installed on a furnace that is still running.”

Fives North American Combustion employs roughly 210 people. Approximately 180 employees are based in Cleveland, while the remainder work in field sales offices across the country. Fives North American Combustion also runs an Alabama-based outfit called North American Construction Services which does not have the ‘Fives’ name in front of it.

With roughly 150 workers, the North American construction services division “does two types of business basically: construction and maintenance. They do rebuild work on big steel or aluminum furnaces. Then, there’s design and build work, which involves more integrated projects with Cleveland. We’ll go out and basically sell a furnace or a system that has our combustion products, and they build a brand-new box,” he says.

“The combustion industry is very unique in that it’s got a lot of black magic or black art to it,” he adds. As such, employees need to have both technical know-how and creative, problem-solving abilities. “I think if you have the willingness to learn and creativity you will excel at our company.”

Fives North American Combustion has ISO 9001 certification and comprehensive quality and safety measures. The company has a quality department and a specific casting quality assurance program. “We’ve had issues in the past with suppliers delivering poor castings. We’re very diligent in making sure [suppliers] are doing their highest quality work because these castings are going to [face] a lot of heat, and we can’t have them fail,” says Dzik.

“As far as quality in general, it goes back to us designing a fairly robust offering. We know that our products are going to be in some fairly harsh environments. We don’t always know exactly the environment it’s going to go, but if you walk around a steel mill, you’re talking ambient temperatures of 150 degrees (Fahrenheit). Things tend not to perform well there. So, we try to design for that,” he continues.

The firm also puts an intense focus on ensuring that the combustion system process controls it designs and develops are in perfect running order. Fives puts its control panels through a rigorous debugging process before sending them to customers. Other companies might “build and then test on-site, but for us, that doesn’t make sense. We have a fully-staffed department. We do all the debugging in Cleveland,” states Dzik.

The company’s safety program encompasses both in-house and on-site measures. In-house safety is maintained through training and field safety observation and dialogue (FSOD), among other things. During a FSOD, a shop employee is carefully watched. If they appear to be doing something unsafe, the observer makes note of this so a remedy can be found. Fives runs another safety program called ‘Find It. Fix It.’

“You’re walking, and you see something unsafe. You don’t just walk past it. You stop. You write it down. You try to fix it. If you can’t fix it, you get someone to come and fix it,” Dzik explains of the program.

Fives is equally systematic when it comes to maintaining the safety of staff members working at a customer’s site. “We take great care with making sure that all people going on-site have all the necessary equipment: PPE [personal protective equipment] and everything else they need. We always abide by the strictest standard. If it’s the customers, we’ll abide by the customer’s standard. If ours is stricter than the customer’s, we abide by ours,” he says.

“I would also mention we have celebrated over a year of no lost time accidents at our facilities which is really great for us and a testament to the things we’ve implemented to ensure that the safety is being taken seriously by every single employee,” adds Schodowski.

Thanks to COVID-19, most trade shows and industry events have been cancelled, so Fives is using other means to promote itself.

“Most of what we’re doing now [involves] a lot of digital content. We’re making sure we’re staying active on LinkedIn. We are still fully-functioning as a company right now. We still have our sales team constantly contacting [people],” says Schodowski.

Fives North American Combustion also has a website and a YouTube channel, “with videos, for help on combustion problems,” adds Dzik.

Once the COVID-19 pandemic passes – and Dzik says he hopes it turns out to be “a fairly short-term challenge” – the company has major ambitions. “Our goal is obviously to be the number one company that comes to mind when thinking of the thermal process industry. That is the five-year plan. In order to do that, there are a lot of things we need to do. There are a lot of competitors in this space, but if we keep a focused market plan, I think you’ll quickly get there in five years,” he states.