Nanotechnology has the potential to make airplanes, cars, and consumer goods lighter, stronger, and more durable. It is a safe bet that this extremely small-scale technology will have a huge impact on manufacturing, among other sectors.

With ‘nano’ meaning one-billionth, a nanometre is one-billionth of a metre. “There are 25.4 million nanometers in one inch. A human hair is approximately 80,000 – 100,000 nanometers wide,” according to the National Nanotechnology Initiative (NNI), a U.S. government research and development program. Nanotechnology, therefore, is “science, engineering, and technology conducted at the nanoscale, which is about one to 100 nanometers,” continues NNI.

When working at a molecular level, it is possible to tweak the structure of various materials to alter their basic properties for the better.

“As we rearrange and reduce the complexity of chains of molecules, a given material may become stronger, more flexible, more durable, lighter weight, better able to resist temperature extremes, more resistant to environmental and other types of corrosion,” says Industry Week magazine in a May 27, 2019 article.

The ability to fashion stronger but lighter building materials has some pretty obvious benefits for anyone in manufacturing. In fact, there is an entire subset of nanotechnology called nanomanufacturing.

According to the NNI, there are two main nanomanufacturing methods: a ‘top-down’ approach, which entails removing excess material until the component is nanoscale, and a ‘bottom-up approach.’ The latter involves using molecular-scaled components to build.

Regardless of the approach taken, nanomanufacturing fits perfectly with the trend towards ‘lightweighting,’ that is, using new materials to make such products as cars and planes stronger but lighter than their traditional counterparts, thus saving on fuel costs.

Transportation industries may be fuelling the nanomaterials sector more than any other, according to the Industry Week article. “Pressures based on environmental concerns and all the politics around the cost of oil means our automobiles need to be more efficient and a lot faster than they have been.” And the same applies to aerospace transportation, which sees significant fuel savings from lighter weight, higher strength materials.

In addition to lighter vehicles, a whole slew of other consumer products might benefit from nanotechnology, making them durable yet lightweight. They are already being used in tool housings, sports equipment, protective headgear, automotive parts, and suitcases.

Ceramic coatings that have been subjected to nano-level tweaking have proven tougher than conventional coatings on machine parts, continues the NNI. Inexpensive but superior thin-film solar panels are another potential nanomanufacturing market segment.

“Nanotechnology can be incorporated into solar panels to convert sunlight to electricity more efficiently, promising inexpensive solar power in the future. Nanostructured solar cells could be cheaper to manufacture and easier to install since they can use print-like manufacturing processes and can be made in flexible rolls rather than discrete panels,” explains the NNI.

“Nanoscale transistors may someday lead to computers that are faster, more powerful and more energy-efficient than those used today,” reports the NNI.

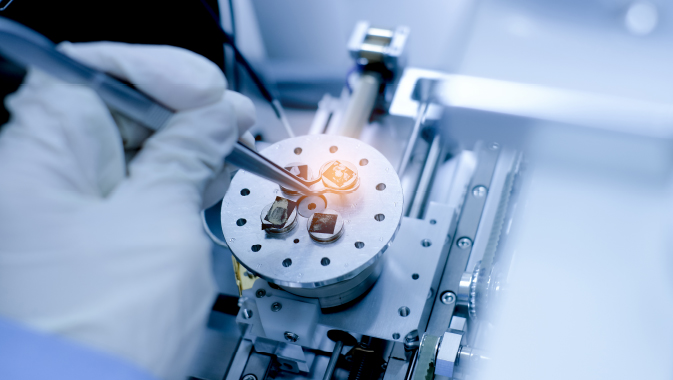

Given the incredibly tiny sizes involved, nanotechnology requires some very unique tools and techniques.

“Nanotechnology tools and instruments are the hardware, software, and supplies used to measure and manipulate structures on the nanoscale. They include microscopes, probes, lithography systems, manipulation and fabrication systems, software and other accessories,” explains a report from Business Communications Company (BCC), a market research firm.

New companies are emerging to fill the demand for such tools and instruments. Nanodevice Solutions Inc. (NDS), for example, is an engineering firm in Waterloo, Ontario, that designs and fabricates probes for atomic force microscopes (AFM). The microscopes, which are cheaper than electron microscopes, can produce high-resolution images that are just as good. These are used in the design and testing of nanoscale devices.

The company’s AFM probes can be used in various industrial and engineering applications such as nanoscale imaging, advanced material development, or advanced manufacturing.

German firm SIOS offers a nanopositioning and nanomeasuring machine called the NMM-1. The SIOS nanopositioning and nanomeasuring machine is the most accurate commercial positioning and measuring machine in the world,” claims SIOS.

“The NMM-1 is a measuring machine for three-dimensional coordinate-measurement in a range of 25 mm x 25 mm x 5 mm with a resolution of 0.1 nm,” says the company, adding, ”[The NMM-1 has] a 3D-multisensor positioning and measuring system with the highest accuracy.”

The system can be used to examine precision lenses and membranes “as well as for processing and measurement of microelectronic, micromechanical or optical objects.” Applications are found in: “positioning, manipulation, processing, and measurement of objects in the fields of micromechanics, microelectronics, optics, and microsystems engineering with nanometric precision within a large range,” continues SIOS. Other uses include “measurement of precision parts such as the tips of hardness testing probes, membranes, and microlenses.”

Lenses are the market in which Texas firm Peak Nano is eager to make a splash. According to the company, Nano Peak specializes in optics systems that use nanolayer gradient refractive index (GRIN) lenses. The company developed its nanolayer technology for military use and only made it available to the public in 2016.

The technology, according to Peak Nano, is “like stacking nano-sized building blocks to create a new lens. We begin the process by combining hundreds of nanolayered polymer films, comprised of thousands of layers just tens-of-nanometers thick – roughly 10,000 times less than the thickness of a human hair. The result: a revolutionary ability to create and customize the power of ultra-high-performance lenses.”

The firm’s nanolayer GRIN lenses can be used in various sectors, including military, medical, and commercial for night vision, binoculars, or rifle scopes, surgical optics, endoscopy, microscopy, diagnostic imaging, drones, telescopes, cameras, or binoculars.

Peak Nano might just be onto something. An article in the February – March 2017 issue of Outdoor Life magazine described using specifically engineered polymers as “the most disruptive technology in optics in our lifetime.” The same article referred to Peak Nano as the industry leader in this field.

With this in mind, what does the future hold for nanotechnology tools and techniques used for manufacturing purposes? Plenty, if current research and development work bears fruit.

“An international team of researchers has reported a breakthrough in fabricating atom-thin processors,” reports a January 24, 2019 article in Science Daily, adding that the discovery “could have far-reaching impacts on nanoscale chip production and in labs across the globe where scientists are exploring 2D materials for ever-smaller and faster semiconductors.”

A team headed by a professor from New York University Tandon School of Engineering “demonstrated that lithography using a probe heated above 100 degrees Celsius outperformed standard methods for fabricating metal electrodes on 2D semiconductors such as molybdenum disulfide (MoS2). Such transitional metals are among the materials that scientists believe may supplant silicon for atomically small chips. The team’s new fabrication method – called thermal scanning probe lithography (t-SPL) – offers a number of advantages over today’s electron beam lithography (EBL),” continues Science Daily.

Ideally, t-SPL technology will allow researchers to move nanofabrication out of expensive, high-technology clean rooms and into individual laboratories.

Meanwhile, Nanowerk News, a source for nanotechnology information, reported in a March 14, 2019 bulletin that an assistant mechanical and aerospace engineering professor at Missouri University of Science and Technology has received a five-year, $500,000 award. The award will assist the professor in using nanocrystals to build large-scale nanostructures.

The award money, which comes courtesy of the National Science Foundation (NSF), will help the professor create an innovative method of using several materials to manufacture practical nanostructures. “The research could lead to advances in solar cell and battery technology, nanophotonics (the study of how light behaves on the nanometer scale), and the development of metamaterials, which are materials engineered to exhibit properties not found in naturally occurring materials,” continues the bulletin.