Altec Integrated Solutions designs and manufactures precision machinery and advanced controls equipment. Its control systems link Altec’s involvement in both veneer and plywood manufacturing and amusement park rides. This is made possible by control platforms, or programmable logic controllers (PLCs) that are used in both industries to regulate processes and program them to behave in a specific way.

~

Altec manufactures machinery for the forest product industry and entertains tens of thousands of guests around the world with safe, fun and exhilarating experiences on some of the most famous rides in the industry.

Even its early days, Altec Integrated Solutions was already a respected problem solver in the lumber manufacturing industry. In 1999, the founders saw a gap in the market and the company quickly evolved into an innovative control systems and high-tech mechanical optimization provider. Its inventions set out to increase the recovery and optimal use of timber, improving production rates and the quality of rendered lumber, veneer, and plywood.

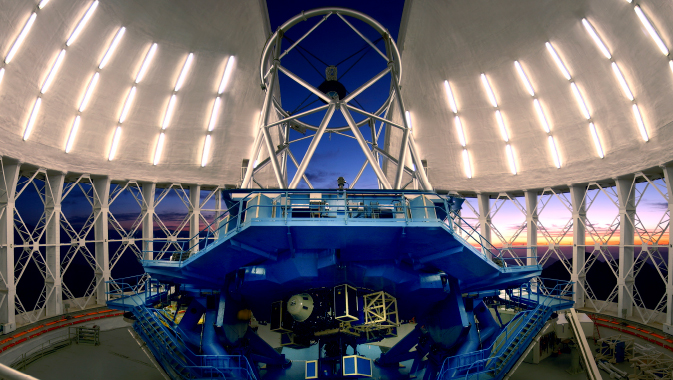

The amusement park rides came later, and had a very interesting start. In 2003, Altec received a phone call from Dynamic Attractions (known at the time as Coast Steel Fabricators) who found its number in the yellow pages. The client was in Hawaii and had great need of Altec’s services. Always there to help, founder Bill Long got on an airplane and was on site in no time. The problem, however, was not ride-related, but telescope-related. He corrected the problem and was called back to work on more projects over the next few years. At this time, Dynamic Attractions was just getting into the entertainment industry. The structural-steel fabrication company built telescopes and executed other interesting projects all over the world, including work for Walt Disney. Altec’s involvement started small, and things grew from there.

Today, Dynamic Attractions, Ltd. is a world-leading ride vendor and has fabricated some of the most popular and exciting rides in top international amusement parks. Altec is very proud to be its preferred control systems supplier.

Altec Integrated Solutions was started by Bill, his wife, Jasna, and their former partner, Craig Markovic. Initially, the trio worked from Bill’s basement office in Vancouver, Canada. Since then, Bill has led Altec from a three-person startup 18 years ago, to an organization with 65 employees in two countries and customers in many others.

The man who was instrumental in making Altec famous for its systems controls was Michael Dill. He joined the company in 2004 and is one of its longest serving employees. Mike came from the automotive industry in Ontario, where he provided vehicle manufacturers with control systems throughout North America. At first, Mike designed these systems for both industries, but in later years, his focus was on design and programming solely for the entertainment industry. Mike became a partner and Engineering Manager in 2012.

Another mover and shaker in the company since 2009 is Chris Bartlett, Vice President of Sales. With 33 years of sales experience here and abroad, his contribution to the company has been invaluable. Following the financial crisis of 2008, Chris expanded Altec’s plywood and veneer department by signing new customers like Georgia-Pacific and Boise Cascade, amongst others. Times were tough then, but his efforts paid off when the market rebounded in 2012. He also helped promote the replacement of hydraulic cylinders with electric actuators on the machines that Altec controlled. The company pioneered this technology and is still the recognized leader, globally.

For 12 years, the business showed steady growth. It really took off around 2012, and in the past six years, business has exploded. Altec was recently recognized for this achievement by Growth 500 (previously named Profit 500), with an award given to a Canadian company that has shown significant growth over five years.

For nearly two decades, the company’s creativity and passion for innovating solid solutions to the toughest challenges in both the amusement ride industry and the veneer and plywood manufacturing industry has caused it to boldly push every boundary it has encountered. This has made Altec a leader in two contrasting, high-tech industries, allowing it to blend the knowledge and experience of each to advance both.

The company’s clients include ride vendors like Vancouver-based Dynamic Attractions, Swiss rollercoaster manufacturer Bolliger & Mabillard, and other international giants. Altec has supplied the ride control systems for many premier attractions in the world’s greatest amusement parks, while veneer and plywood manufacturers such as Georgia-Pacific have used Altec since the beginning. Its machinery manufacturing expansion led to the acquisition of Demco Manufacturing, Inc. of Diboll, Texas in 2016.

Some of Altec’s most famous equipment for the plywood and veneer industry includes the XY Scanner, Veneer Lathe Control System, Thickness Quality Monitor and more, while its custom machinery includes the Altec Electric Charger, Altec/Demco Carriage, Altec Electric Actuators, Altec Clipping Trash Gate and much more. These have all been installed in diverse locations around North America and Altec is planning to spread its footprint globally in conjunction with Demco Manufacturing.

Altec employs 40 employees in Vancouver and 25 in Texas. “The work we do is inspiring; it’s really cool,” says Bill. “Both industries are very technical and challenging. Our workforce enjoys that challenge.”

Staff members are highly valued and the company is a fun place to work. Chloë Derksen, Marketing Coordinator, is full of praise for the extra-curricular activities that incentivize colleagues. Twice a year, everyone gets together at company events and a special in-house program allows people to share peer-to-peer recognition. There’s a great atmosphere. People’s work is appreciated and they get the recognition they deserve. “Our open-door policy really creates a team feeling. You can pretty much walk into anyone’s office and get their opinion or help,” she says.

Altec also has a big heart when it comes to the environment. The company feels strongly about the fact that wood is a renewable resource and that using it in construction sequesters carbon. It believes that the more wood is used in construction – combined with reforestation – the more carbon is absorbed from the atmosphere. The team also aims to reduce waste and energy usage wherever possible. Altec’s other great environmental victory is its famous electric actuators that replace traditional hydraulic cylinders, mentioned earlier. These are much more energy efficient, significantly reducing consumption in the manufacturing process. By reducing the use of hydraulic systems, users also reduce the use of hydraulic fluid, a petrochemical-based, environmentally hazardous substance.

With the incredible responsibility that comes with the nature of its business, Altec has a proven track record of sterling customer care. Everybody here cares. Every call is responded to with attention to detail and quick response time. Technical and engineering staff are on standby 24/7. Even if a call comes through in the middle of the night, issues are seen to. The company takes listening to its customers very seriously and feedback is welcomed. To this end, Altec has implemented an ISO 9001 quality management system, ensuring that products consistently measure up on the international playing field. Participation dictates a commitment to collecting customer feedback and ISO International Standards guarantee that products and services are safe, reliable and of good quality.

Of course, finding, mentoring and developing young talent is paramount to Altec’s long-term success. To achieve this, the company offers a scholarship in partnership with the British Columbia Institute of Technology, or the BCIT Foundation, to qualified students. It includes an eight-month work term at Altec and a monetary award. This initiative allows the company to evaluate and source the best talent from BCIT and to provide hands-on work experience and mentoring to promising students. To date, every recipient of the award returned to work at Altec upon completing school. The company also implemented, and continues to develop, formal safety, quality control, management and marketing programs to support its growth.

Chris and Bill are actively involved in managing the day to day running of the company. “It’s still run as a small business although we’re definitely in a transition phase to becoming a larger organization,” says Chris. The directors are in agreement that Altec will keep its open-door personality and its intimate feeling of involvement and connection throughout its expansion. “As it gets bigger, things change, but we would hope to retain as much of that small business feel as we can,” Bill says.

Early on, Craig Markovic came up with the phrase: “One of the distinguishing features of the firm’s culture is the continuous search for better ways to respond to client’s needs.” Altec’s success is a result of helping to make its customers successful. Honesty and integrity form the backbone of its company ethos. Hard work, attention to detail and delivering on its promises are also part of that legacy.

Bill’s advice on achieving success is simple: he believes that there is no getting around hard work and that you need to get the little things right; there are no shortcuts. Be honest with your customers and work to build relationships that last, as repeat business is the most important kind. When it comes to competition, he agrees with Henry Ford: “The competitor to be feared is the one who never bothers about you at all, but goes on making his business better all the time.”

Competitors, take note. This year, Altec Integrated Solutions is expanding on its promise to remain the leading systems control developer in both the amusement ride and plywood and veneer industries. The team’s focus is on an unbeatable combination of improving existing design and innovation, quality, excellent customer service and, needless to say, a good heap of exhilaration.