Precise and versatile cryogenic processes, including cryogenic deflashing, deburring, dry ice blasting, and part-enhancing processes, are highly effective treatments for improving product quality. In addition, they are also fast. Such treatments improve part performance and reliability while saving customers time and money, and few companies offer as many solutions as Nitrofreeze® Cryogenic Solutions.

“We offer the most comprehensive array of cryogenic services for the manufacturing industry under one roof in all of North America,” says Assistant General Manager Ryan M. Taylor. This is a bold statement, but the truth is, no other supplier even comes close to Nitrofreeze.

Some solely do cryogenic treatment, cryogenic deflashing, or cryogenic deburring. Others handle just deflashing and deburring, and some focus only on cryogenic treatment, thermal cycling, or shrink fitting. By providing all these services and more, such as thermal cycling, helium processing, dry ice blasting, other cryogenic part-enhancement processes, and equipment rentals, Nitrofreeze Cryogenic Solutions truly functions as a one-stop shop.

“That’s how we set ourselves apart,” Taylor says, although he notes that the company also performs process development work and qualification runs for some customers, including performance and operational qualification.

Strong core values

The respected Cryogenic Institute of New England, Inc. stands in the City of Worcester, Massachusetts. Operating under the brand name Nitrofreeze Cryogenic Solutions, it’s referred to by many simply as Nitrofreeze. Certified to both ISO 9001:2015 and International Traffic in Arms Regulations (ITAR) standards, Nitrofreeze is the kind of company that clients of all kinds trust completely to get the job done quickly and professionally.

With the well-defined mission, “Serving, enabling, and empowering others is our greatest opportunity to make a difference!” Nitrofreeze’s strength comes from sturdy values such as integrity, exceeding customer expectations, and being a respected part of the Worcester community.

Internally, these values extend to the whole team, with the company creating a culture that welcomes opportunities for advancement, supports respect, dignity, and diversity, and operates with the utmost respect for safety and the environment. This spirit exemplifies Nitrofreeze’s commitment to provide customers with a competitive advantage through the use of cryogenic technologies while adhering to core values of integrity and strict workmanship standards.

Quality and service

The company’s story began around 2001, when Robin Rhodes purchased a Connecticut company called Nitrofreeze, which specialized in cryogenic treatment. As the new owner and president, Rhodes soon moved the business to Massachusetts.

Realizing cryogenic treatment alone wasn’t enough to expand the business, he set up additional services to enable growth and brought in deflashing machines from California. To ease the handling and delivery of the nitrogen tanks, Rhodes moved the company from an upper-level old mill space to a ground-level location.

“Rhodes started deflashing as a service, and realized there was growth there,” Taylor explains. “And that side of the business has been our main driver for nearly 20 years.”

Taylor himself, who had been with Nitrofreeze Cryogenic Solutions from 2007 to 2014, brought his extensive background in sales, marketing, and business development back to the company about three and a half years ago. He realized during his first tenure that although the company had a website, it wasn’t actively marketing its deflashing and deburring capabilities. It wasn’t long before these services were being extensively advertised, setting off “astronomical growth.”

In 2010, the company purchased its own 5,000-square-foot building and, prompted by the growing demand, went from one deflashing machine to four in a matter of just a few years.

Today, Nitrofreeze provides cryogenic services and equipment to clients in numerous industries. Key sectors in recent years have been medical and automotive, as well-known car manufacturers are opening or expanding plants across the United States.

The bulk of Nitrofreeze’s work deals in small, intricate parts, ranging from parts like Teflon and silicone gaskets—half the size of a pinky nail—to surgical caddies at the larger end. Used in operating rooms, these medical-grade caddies are usually made of polypropylene and hold surgical instruments. “We run one at a time, and they’re flawless when they come out,” Taylor tells us.

On the automotive side, Nitrofreeze recently did some work on molded parts used inside Mercedes-Benz, BMW, and Audi headlight enclosures. “If you’ve got something that’s a [quantity of a] million or less, that’s the sweet spot for us,” says Taylor, although the company has processed upwards of 10 million parts per year depending on the part’s respective geometry.

Saving time and money

Removing unnecessary bits known as burrs from parts by hand is expensive, tedious, and slow. Taylor has been in factories where employees at conference-sized tables were using microscopes to perform deburring. And of course, parts can’t be deburred by hand anywhere near as quickly as they can using Nitrofreeze’s services, to say nothing of the risk of contracting carpal tunnel syndrome over time.

“[Our advantage] is multifaceted,” says Taylor. “The first aspect is time, and time is money. Instead of paying employees, we can run hundreds or even more than a thousand parts per hour, and turn parts around in two business days.” Usually, lead times are between two and five business days, with same-day and next-day services available at an additional cost.

“Most of what we do is thousands of parts at a time,” Taylor says, as he describes the risks of deburring by hand. “If you take off too much material, you’ve got a scrap part. But our process is largely non-abrasive. We’re not freezing the part all the way through; because the flash and the burrs are so much thinner, that’s what freezes. And when they start ‘tumbling,’ that’s what removes some of it, and then blasting does 80 percent of the work.”

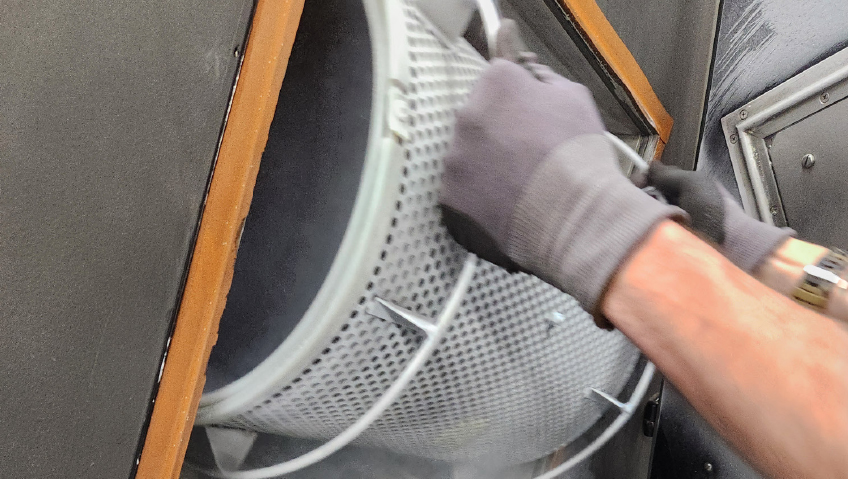

Deflashing is for molded parts made from silicone, urethane, rubber, or plastic. For proper function, extraneous material must be removed. These parts are chilled with gaseous nitrogen, tumbled, and blasted with fine polycarbonate media that’s almost sand-like. Once this is done, the parts are cleaned and dried. If a customer requests additional cleaning, this can be done in an isopropyl bath or a wash. The same process applies to deburring.

“Predominantly, we are working with four forms of material,” Taylor explains. “We are doing plastics, rubbers, some aluminum, and some forms of stainless steel.”

As Assistant General Manager, he is optimistic about the future of Nitrofreeze. This year, the company is on track to see eight to ten percent growth, and one of his goals is to enhance Nitrofreeze’s partnerships with manufacturers of the equipment the company is currently using and selling to customers.

“On the service side, the three drivers are deflashing and deburring, which I group together; dry ice blasting, which is an opportunity; and then cryogenic treatment,” he says. “I’d like to see us do more deflashing and deburring, that being the main driver, but also see the other two lines pick up. It would be nice to get more machine cutting tool customers and a more regular cryogenic treatment line. We continue to push the deflashing, deburring, and dry ice side of the business—I think that’s the opportunity to grow for us.”