When you think about companies leading the way in remanufacturing, reverse logistics, and sustainable technology, few stories are as compelling as that of SRC Technologies Group. Formerly known as SRC Electrical, this Springfield, Missouri–based company is part of the larger SRC family of businesses, an organization with deep roots in employee ownership, transparency, and forward-thinking innovation.

Today, under the leadership of General Manager Chris Kleinfeld, SRC Technologies Group continues to redefine what it means to blend tradition with transformation. From pioneering employee ownership models to embracing the future of semiconductors and electric vehicle (EV) technology, the company has become a standard-bearer for how manufacturing organizations can evolve while staying true to their core values.

The origins of SRC trace back to 1983, during a time when the U.S. economy was struggling and International Harvester was bleeding cash. Layoffs were rampant, and one of its Springfield, Missouri factories, an International Harvester Renew Center, was put up for sale.

A small group of determined leaders saw an opportunity. They scraped together $100,000 and leveraged it into an $8.9 million loan to purchase the facility. That bold move marked the birth of Springfield Remanufacturing Corp.

This moment has since become legendary in American business history, a story often cited as one of the most daring and successful employee buyouts. It was risky, highly leveraged, and took years of grit and discipline to stabilize, but it set the tone for a company culture where bold decisions and shared responsibility became the norm.

Building identity

Over time, the company evolved into SRC Holdings, an umbrella for multiple operating entities. In 1991, the foundation for what would eventually become SRC Technologies Group began as a joint venture with Case called Megavolt, focused on remanufacturing starters and alternators. That venture lasted until 2007, when the group became a standalone entity under the holdings umbrella and rebranded as SRC Electrical.

Fast-forward to 2025, and the company has once again rebranded, this time as SRC Technologies Group to better reflect its expanding portfolio of products and services. But why the rebrand?

The decision wasn’t just cosmetic; it was about aligning the company’s identity with its strategic vision. Over the years, SRC Technologies Group has grown far beyond its initial focus on rotating electrical components. Joint ventures with global leaders like John Deere introduced the company to electronics remanufacturing. Later, diversification into control modules, marine electronics, and even propulsion batteries reshaped the company’s scope. “That’s really the large reason we rebranded as SRC Technologies Group, because we have multiple technologies under our umbrella,” Kleinfeld explains.

The new name reflects this technological diversification while keeping the company grounded in its remanufacturing roots. It also signals to partners and the market that SRC is ready to compete not just as a component specialist, but as a broad-based technology group with expertise across multiple industries.

Employee ownership

While many manufacturing companies tout innovation and diversification, few have a model as unique as SRC’s. The company is 100 percent employee owned and guided by a management philosophy known as The Great Game of Business. “Our primary focus is creating equity for our shareholders,” says Kleinfeld. “But our shareholders are our co-workers, our co-employee owners that we work with every single day, which makes it much more personal.”

At SRC, open-book management means financial information is shared transparently across all levels of the organization. Employees aren’t just workers; they’re financially literate businesspeople who understand income statements, balance sheets, and the direct impact of their decisions. Kleinfeld is especially proud of how this empowers the workforce: “Our direct folks working on our shop floor are extremely financially literate, well versed in going through an income statement and balance sheet. They know how the business really runs, so they can make good decisions every day.”

The benefits of employee ownership extend beyond the workplace. Many employees apply their financial literacy at home, improving their personal finances and creating generational wealth. Long-tenured team members have seen their stock ownership compound into life-changing figures. The company distributes updated stock certificates annually, a tangible reminder that one’s daily work directly drives their financial future. Few organizations in the industrial space can claim that level of alignment between ownership, culture, and results.

The fourth ‘R’ – remanufacturing

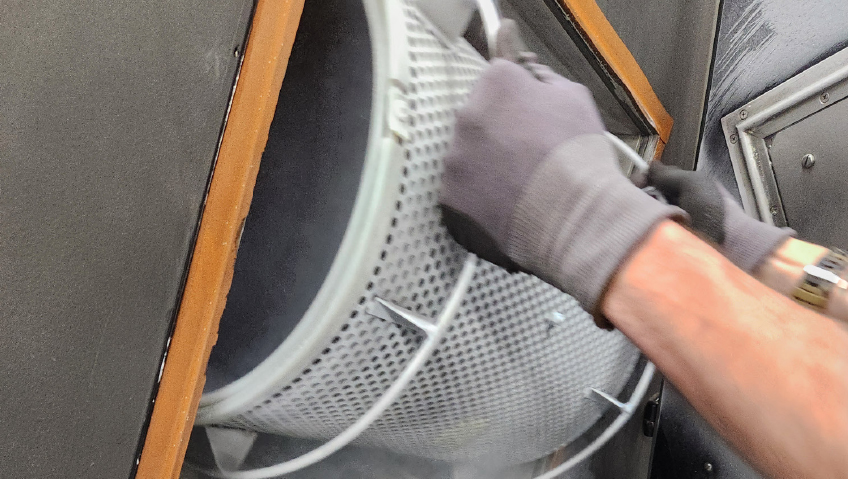

SRC Technologies Group has built its reputation on being a leader in remanufacturing, the process of restoring used products to “like new” or even better-than-new condition. The environmental and economic benefits are significant; instead of discarding components into landfills or recycling them for raw materials, remanufacturing preserves more value, reduces carbon footprints, and lowers costs for customers.

“Rather than recycling, we’re regaining a lot more value,” Kleinfeld explains. “The carbon footprint is far improved, where the amount of energy required to remanufacture a starter is a whole lot less than producing a new one.”

This philosophy applies not only to traditional products like starters and alternators but also to cutting-edge technologies. Electronics remanufacturing, for example, has become a vital part of the company’s operations, covering everything from engine and transmission control modules to marine displays under its Clear-Cast Marine brand.

Remanufacturing isn’t just about the product; it’s also about the process. That’s where reverse logistics comes into play. SRC recognized early on that remanufacturing requires a sophisticated system for tracking, exchanging, and accounting for “core assets,” the used components that come back from the field. To address this, SRC Logistics, one of the operating entities within the SRC family, developed its own proprietary software. This system helps OEM partners and dealerships manage everything from inventory to shipping, ensuring a seamless flow of parts. Today, that system is deployed in more than 10,000 dealerships worldwide. It’s a testament to how deeply SRC understands not just remanufacturing, but the entire ecosystem surrounding it.

A new era

Perhaps the most exciting new frontier for SRC Technologies Group is in semiconductors. The global chip shortage of recent years highlighted the fragility of supply chains and the urgent need for domestic solutions. For SRC, the opportunity wasn’t in building new semiconductor fabrication plants but in looking at the waste streams, the discarded electronics from vehicles, trucks, and tractors.

As Kleinfeld explains, “So much of electronics waste is just getting ground up to extract precious metals. From a value extraction standpoint, it makes sense, but it makes a whole lot more sense if you can extract functioning components.”

With support from the CHIPS Act and grant funding through the Jordan Valley Innovation Center (JVIC), SRC Technologies Group is developing processes to harvest and reuse semiconductors from discarded electronics. These chips can then be reintroduced into supply chains, helping OEM partners bridge the gap during shortages.

This approach is uniquely aligned with SRC’s expertise in remanufacturing. Just as the company gives a second life to engines and alternators, it is now pioneering methods to give semiconductors a second life, one that’s critical for industries from automotive to agriculture.

The work isn’t easy; as Kleinfeld notes, there are “many nuances to ensure that you have properly validated and reprocessed that semiconductor in a way where it can be introduced into supply chains in new production in a robust way.” But with validation underway and growing industry demand, this initiative could put SRC at the forefront of a new era in electronics remanufacturing.

A clear vision

For Kleinfeld and his team, the vision for the future is clear: SRC Technologies Group will lead SRC from a technology perspective, driving diversification into emerging markets.

The company is positioning itself strongly in the EV space, where demand for remanufactured propulsion batteries is set to grow. Its new battery lab already supports refurbishing efforts across highway, agricultural, construction, and marine applications.

Electronics will also continue to be a central focus, particularly in agriculture, construction, and commercial vehicles. And while the marine division under Clear-Cast Marine is relatively young, it’s expected to expand rapidly. In Kleinfeld’s words, “It’s really all about technology-based diversification for the organization.”

That diversification doesn’t just mean new products; it means new ways of thinking about value, ownership, and responsibility. From financial transparency to sustainable manufacturing practices, SRC Technologies Group is building a model that other companies, both inside and outside manufacturing, can look to replicate.

From its scrappy beginnings in 1983 to its current position as a leader in remanufacturing and technology diversification, this company has consistently embraced challenges as opportunities. Its unique employee ownership model creates alignment between vision and execution, while its open-book management style builds trust, literacy, and accountability. Add to that its expertise in reverse logistics, its growing presence in semiconductors, and its role in sustainable technologies like EV batteries, and it’s clear that SRC Technologies Group isn’t just keeping up with the times; it is shaping the future.

For industries wrestling with supply chain uncertainty, environmental responsibility, and technological change, SRC offers a model worth watching. It proves that when employees are true owners, when transparency is non-negotiable, and when innovation is embedded in the culture, businesses don’t just survive—they thrive.