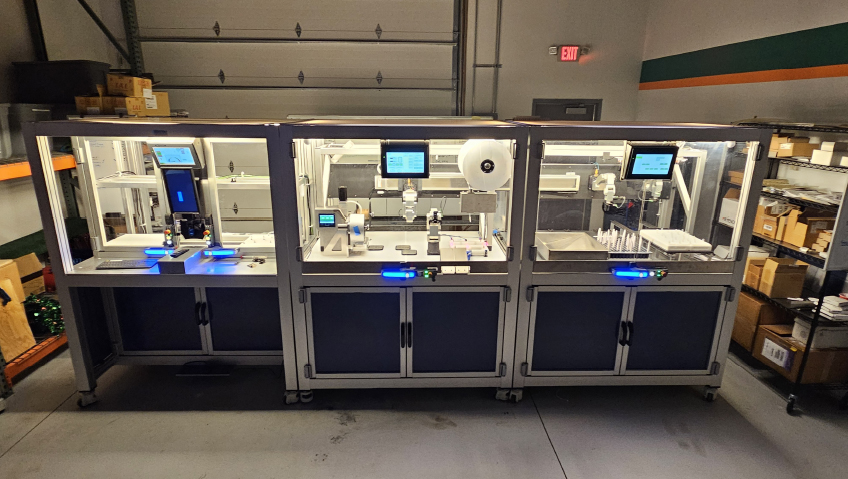

In a small but mighty facility in the southeastern United States, a team of engineers is quietly revolutionizing the way manufacturers approach automation. SEYMOUR Advanced Technologies, founded just months prior to the onset of the COVID-19 pandemic, has evolved into a powerhouse for high-precision, custom-built automation systems. Its clients span demanding industries such as pharmaceuticals, aerospace, defense, and micro-electronics.

What sets SEYMOUR apart is not just its groundbreaking technology but also its relentless drive to deliver smarter, faster, and more accurate solutions. These systems often work with components smaller than a millimeter, parts that are difficult or even impossible to manipulate by hand.

“We’re not just putting parts together,” says Robert Seymour, founder of the company. “We’re putting the right parts together and verifying they’re assembled correctly, every time.”

With a background in engineering and years of experience building automation machines, Seymour recognized a gap in the manufacturing process. While automation systems were becoming more advanced, they often lacked meaningful integration with the people operating them. Valuable engineering data was rarely shared with factory floor operators, creating inefficiencies.

“Not all the information the engineer used to make the machine was provided to the end user,” Seymour explains. “But it was really relevant to how the machine was operating. My goal was to bring all that up to the end user, so they know in advance that the machine’s not performing as well and why.”

This foundational idea is to empower the end user, and it continues to shape the company’s mission. SEYMOUR machines don’t just do the job; they understand the job, track the process, and report on performance in real time. This approach bridges the communication gap between engineering design and shop floor execution, leading to more informed decision-making and minimized downtime.

The company specializes in what Seymour calls “micron-level inspection and placement.” This means aligning and assembling components so tiny they can’t be seen with the naked eye. One of the team’s standout accomplishments was developing a system to align and insert ultra-fine wires into hollow medical needles, a task so precise that it demanded innovation in both hardware and software. “We developed proprietary technology in 3D vision systems to align two 6-axis robots with these wires and needles,” Seymour recalls. “We did amazingly well on that, and we got a lot of feedback from the industry.”

This success underscored the company’s expertise in creating zero-failure solutions in high-stakes environments, from medical devices to defense components. These precision tools require not only careful assembly, but also thorough inspection and flawless verification. In order to inspect and align parts at the micron level, SEYMOUR’s systems offer 10 times the resolution of the components they handle. This ensures every movement, every placement, and every decision made by the automation system is rooted in accuracy. When the tolerance for error is less than the width of a human hair, the only way forward is absolute precision.

SEYMOUR’s ability to innovate so rapidly stems from its vertically integrated structure—every stage of design, development, and production happens in-house. This includes the use of 3D printers for both metal and plastic, advanced vision systems, and proprietary software. “We control the whole project from start to finish,” Seymour explains. “From design all the way through proof of concept into the project itself. We can control each iteration of the part and the programming.”

This setup enables the team to go from design to prototype in a matter of hours and deliver custom systems in as little as five months. By handling everything internally, the company avoids the delays typically caused by outsourcing and ensures a tighter quality control loop.

Rapid prototyping, too, gives SEYMOUR a critical edge. In an industry where time often equates to money, SEYMOUR can deliver complex solutions in record time. If a part needs refining or a design needs adjusting, it can be redesigned, printed, and tested within the same day.

Moreover, vertical integration enhances customer service. Because all aspects of development are under one roof, SEYMOUR can offer more personalized, flexible solutions tailored to the specific needs of each client, a level of responsiveness that builds strong, lasting relationships and creates opportunities for continuous improvement.

Indeed, SEYMOUR’s machines are not just designed to build products; they are built to understand the process. Each system verifies that assemblies are correctly completed and offers full traceability and diagnostics. The company’s systems provide real-time performance data, trend analytics, and predictive diagnostics. In industries like medical and aerospace, where a single error can be catastrophic, this kind of accountability is invaluable, and this emphasis on visibility and insight leads to smarter production lines where operators can identify and resolve inefficiencies before they escalate into costly problems. SEYMOUR’s machines become a central source of truth for quality and performance, and clients gain more than a machine—they gain a living database of performance metrics and process knowledge. This transparency allows operators and engineers alike to optimize their systems over time.

What’s more, SEYMOUR’s integration of AI-driven analytics allows clients to not only react to issues but to proactively prevent them. Over time, the machine learns from previous runs, making each production cycle smarter than the last.

Despite the complex technical work they do, SEYMOUR fosters a laidback but highly effective internal culture. Employees are expected to take ownership, ask questions, and drive solutions. “We’re not here to babysit,” Seymour says. “Everybody’s more than capable of performing at and above expectations.” Instead of rigid supervision, the company values transparency and collaboration. Daily or weekly check-ins keep the team aligned and allow everyone to contribute ideas and problem-solve collectively.

This culture not only encourages innovation but ensures that employees are invested in the outcomes of their work. It creates an environment where people feel confident to challenge ideas, propose alternatives, and continually push the boundaries of what’s possible. “We rely on people to push forth and resolve things, to ask the hard questions and go after the results,” Seymour adds. “That’s what makes our team special.”

This mindset has created a collaborative team environment where engineers, developers, and technicians feel empowered to experiment, iterate, and learn from failure, qualities that drive continuous improvement.

And Robert Seymour’s vision extends beyond his own company. He is passionate about modernizing the Southeast’s manufacturing sector and helping regional companies understand what is technologically possible, and through community outreach, educational partnerships, and collaborative R&D, aims to uplift not only clients but the entire region’s capacity for innovation. The company’s presence signals a shift in how southeastern manufacturers view automation—from a luxury to a necessity. “A lot of times, companies don’t even know the technology exists,” he says. “They’ve been doing it manually because they don’t think automation can help them.”

Thus, when the team visits a new client, it’s not about selling a product; it’s about exploring potential. Automation, Seymour insists, is not a replacement for people but a tool to elevate them. “People are the best problem solvers out there,” he says. “But for repetitive, minute tasks, automation is more consistent. It lets humans focus on solving problems that really matter.”

By automating repetitive or high-precision steps, SEYMOUR helps clients improve safety, reduce error rates, and achieve new levels of productivity all while creating more meaningful work for their own teams.

Now, with demand rising and technology evolving, SEYMOUR is preparing to scale. But its growth will be thoughtful and strategic, preserving the hands-on, iterative process that defines the company. Investments in research and development are positioning the company to stay ahead of customer needs, and as clients continue to seek out smarter, smaller, more adaptable systems, SEYMOUR is ready to deliver. “We’ve brought everything internal—our development area, our testing, our R&D center,” Seymour says. “It’s really starting to pay dividends.”

The company is also exploring ways to bring its solutions to a broader market without compromising the precision and customization that defines its work. Expansion will likely include strategic partnerships and potential new facilities in high-tech manufacturing hubs. In addition, SEYMOUR is considering ways to standardize some of its core modules, enabling quicker deployments without sacrificing its bespoke capabilities. This hybrid model—custom where needed, modular where possible—could unlock entirely new market segments.

By continuing to refine its process and capabilities, SEYMOUR Advanced Technologies is positioning itself as a leader in the future of precision manufacturing. In a world that’s getting smaller and more complex, this team’s combination of high-tech systems and human-centric values offers a compelling roadmap for what automation can truly achieve. “There’s still a consistency in chaos,” Robert Seymour reflects. “And problems are all solvable if you have the right tools.”

In a time when many manufacturers are looking for ways to do more with less, SEYMOUR provides a clear path forward, one where precision, insight, and collaboration aren’t just buzzwords, but the foundation for a new era of smart manufacturing.