Founded on years of firsthand experience, Coventry Industries is a one-stop provider of ammunition machining and engineering solutions.

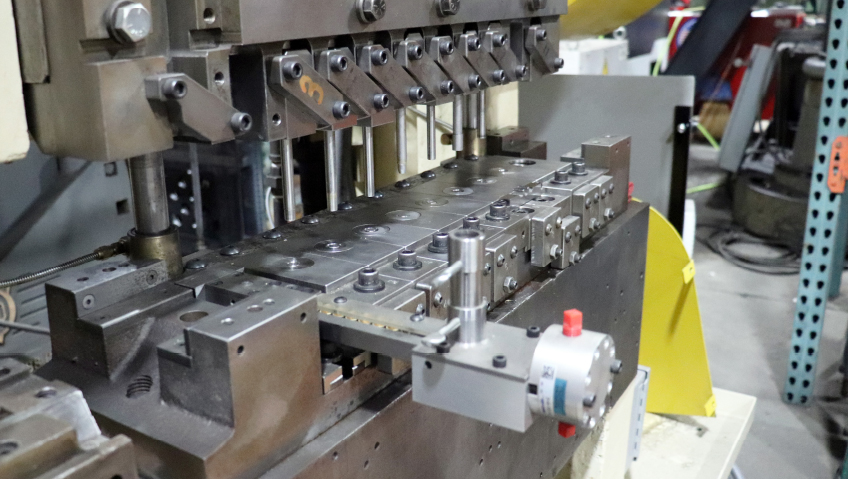

Specializing in building/rebuilding munitions presses, custom machining, fabrication, and much more, the company is outfitted with a full, modern machine shop. With capabilities like CNC, EDM, welding, and waterjet cutting, Coventry prides itself on working closely with clients to meet their ammunition manufacturing goals.

Before creating the company in 2007, Mike Coventry studied mechanical engineering and business. Working for several businesses as a project manager and mechanical engineering manager, he served as an ammunition and defense sales manager, providing clients with new and rebuilt equipment and ammunition/defense manufacturing solutions.

“I was doing contract machine jobs,” says Coventry, President and Owner. “Initially, it was just me sourcing wherever parts needed to be made for people.” He grew the company’s capabilities, making large investments in equipment and machinery, and the business flourished. Today, Coventry Industries has a team of two dozen highly experienced members, including machinists, press builders, and engineers.

Ammunition, tactical, and car audio

While not selling ammunition or firearms, Coventry Industries specializes in building new presses (and rebuilding existing ones) for companies that make ammunition. Unlike some other companies in the business, Coventry goes the extra mile, stocking used machines and presses, and is widely known for its ammunition equipment expertise. The company has grown to include three distinct divisions: ammunition machines, car audio systems (www.coventrycaraudio.com), and tactical gear (www.coventrytactical.com).

Coventry Car Audio Systems provides an array of vital components, including custom bus bars and high-performance lithium batteries, while Coventry Tactical supplies everything from gun cleaning kits to gun magnets, AR500 Steel targets, Canik Optic Plates, Holosun Optics, and more.

Created around 2019, Coventry Tactical represents a progression for the company. “Coventry Industries has been in the ammunition business for a long time, building and rebuilding ammunition presses for some of the biggest ammunition makers in the world, so it seems only natural to spread our wings and move into retail with tactical gear for firearms,” says the company on its website.

“I started doing some car audio work in 2019 and split it off a little while after that,” says Coventry. “We started machining parts for people because there was a need that wasn’t being met.” The car audio division was originally intended for bus bars—which connect electrical power sources—for very loud cars.

Other products on the audio side include LTO lithium battery banks; Rogue Car Audio speakers; voltage, lighting, and compression products; and more. On the tactical side, Coventry saw an increasing demand from customers wanting to mount optics on their pistols. “I made a few, thinking I would sell some, and have been selling them ever since,” he shares.

Indeed, in the 18 years since he founded the company, Coventry has seen a shift in his need for and approach to advertising. With a reputation for professionalism and outstanding quality, Coventry Industries has secured plenty of repeat business, word-of-mouth recommendations from satisfied customers, and a plethora of positive reviews.

While he still reaches out to potential clients, he finds that—more often than not—they approach him first. “More and more, I get contacted by people out of the blue. In the industry, people know about my company and its equipment-building capabilities.” By discussing the components clients wish to make, the Coventry team determines the best machines and presses for their munitions needs.

ITAR, SAM, and CMM

Owing to the nature of its work, the company is certified with ITAR and registered with SAM. ITAR, which stands for International Traffic in Arms Regulations, is governed by the Arms Export Control Act (AECA) and Executive Order 13637, and is a series of U.S. Department of State regulations controlling defense and military technology exports and services. According to the State Department, “The ITAR is regularly updated and revised to reflect changes in technological developments and in U.S. national security and foreign policy interests.”

Since the company is registered with SAM.gov—the official U.S. Government website for the System for Award Management—Coventry Industries is registered to do business with the U.S. Government. In addition, the business is currently working on its CMM Certification for Cyber Security. These certifications and registrations serve to further elevate the company above the competition.

As well as the United States, the company has worked with other ITAR-friendly nations, including Sweden, Mexico, Australia, and Italy.

With a little help from MMTC

In recent years, Coventry Industries has reached out to the Michigan Manufacturing Technology Center (MMTC). Committed to helping Michigan manufacturers “work smarter, compete, and prosper,” MMTC offers practical, personalized consulting services and classes so clients can train and develop employees and management alike.

This includes providing help with government regulations, offering creative business growth strategies, building company-wide operational excellence, and more, according to MMTC and Hollings Manufacturing Extension Partnership (MEP), based at the National Institute of Standards and Technology (NIST).

Coventry Industries faced a challenge concerning the manufacture of optic plates for the firearms sector. Although the promising product showed growth potential, Coventry “didn’t have any space or an individual to machine this part due to its busy workload with other core products and services,” according to MMTC. “With manufacturing shifting toward technology solutions, they wanted to investigate adopting automation to machine this part during the off shift.”

Reaching out to MMTC, a technology opportunity assessment was undertaken, and Coventry Industries’ goals examined. It was determined that the business would benefit from a collaborative robot (cobot) for machine tending, with Coventry able to do “lights-out” CNC manufacturing for optic plates.

This led to MMTC working with Coventry on a two-phase project “to mentor and support the cobot implementation.” Soon, the company was purchasing its own cobot—with MMTC’s help—and integrating it with a CNC machine, and Coventry operators were learning how to program the system. Able to run night and day, the cobot was quickly in place on the production line.

“The implementation of the cobot has been a huge success for Coventry Industries,” said Mike Coventry at the time. “We had our first ‘lights-out’ run of the cobot, which added 14 hours of production to the day. We will continue to look at implementing new technology at the company to facilitate growth and increase our capacity.”

For Coventry Industries, the results of the collaboration tell a tale of success. They include $40,165 in new investment, $30,000 in new sales, retained sales of $25,000, and a 300 percent increase in production.

With this unwavering commitment to precision, innovation, and customer satisfaction, Coventry Industries continues to push the boundaries of ammunition machining, tactical gear, and car audio solutions. From its roots as a one-man operation to a thriving enterprise known for its expertise and leading-edge technology, the company exemplifies the power of adaptability and strategic growth. By embracing automation, securing key certifications, and fostering industry partnerships, Coventry Industries remains a trusted leader in its field—poised for even greater success in the years to come.