Founded in 1995, Vital Materials has evolved from a supplier in the minor metals industry to a global leader in advanced materials with over 10,000 employees. At the core of Vital Materials’ success is its Source to Solutions approach, which utilizes a completely integrated vertical supply chain to partner with customers at every step of the production process—from sourcing raw materials to delivering final systems. This competitive approach allows the company to serve diverse industries such as automotive, mobile, solar, display, glass, and semiconductor technologies.

With a steadfast commitment to sustainability and innovation, the company has developed unique recycling technologies and methods that distinguish it in the industry. Dr. Rajiv Pethe, Technical Product Manager, emphasizes the company’s dedication to sustainability, saying, “recycling and sustainability are key factors for our customers.”

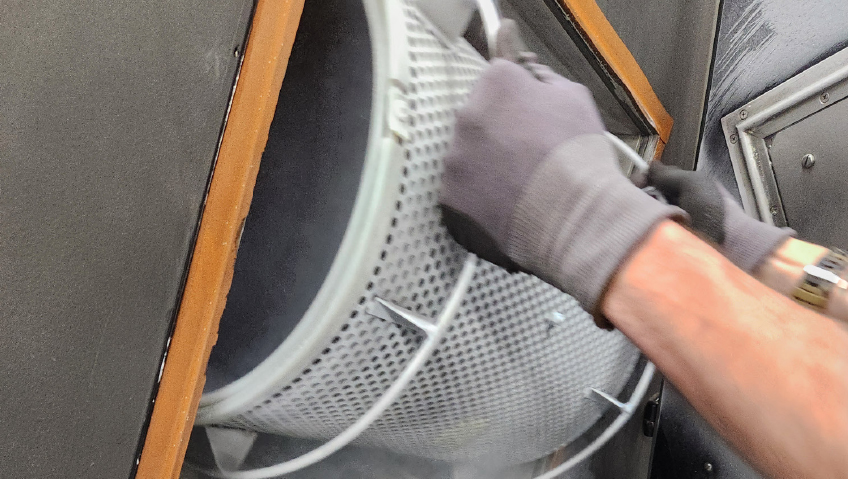

The company uses advanced recycling to recover nearly all rare metal-containing waste, alleviating pressure on natural resources and mitigating the risks associated with material scarcity. “This closed-loop recycling system ensures that a substantial portion of the raw materials we sell are sourced from our recycling programs,” Dr. Pethe explains.

With comprehensive recycling capabilities encompassing the collection, processing, and reintegration of materials into the production cycle, Vital Materials strengthens a circular economy while also providing customers with a sustainable and cost-effective supply chain solution.

Matthew Najera, Senior Marketing Communications Manager, highlights the significance of this approach: “Today’s manufacturers face numerous challenges including resource scarcity, supply chain uncertainty, and environmental impact,” explains Najera. “Our customers are uniquely positioned to maximize the utility of their production process while offsetting costs and meeting their sustainability goals.”

In addition to its closed-loop system, Vital Materials is exploring new methods to enhance recycling efficiency. This includes developing proprietary technologies that can recover materials with even greater precision and purity. “Innovation in recycling is not just about sustainability,” says Najera. “It’s also about creating a competitive advantage by ensuring our customers have access to high-quality materials at a stable cost.”

Given the increasing global demand for rare materials, the recycling technologies developed by Vital Materials have proven essential in industries such as semiconductors and advanced displays, and any industry where the reliable supply of rare materials is critical to manufacturing processes.

This pioneering approach to recycling has since become a cornerstone of the company’s operations, enabling it to expand into other industries while maintaining its commitment to environmental stewardship.

One example of this expansion is the company’s strategic investment in renewable energy solutions. Recognizing the solar industry’s need for critical materials such as selenium, Vital Materials has expanded its production to support a diverse range of photovoltaic (PV) applications. As a result, Vital Materials has become the world’s largest global producer of Indium Tin Oxide (ITO) targets, a material that enables display and photovoltaic efficiency by optimizing light transmission and conductivity.

To maintain this robust pipeline of new materials and stay competitive with the rapid pace of technological advancement, Vital Materials continuously invests in R&D, ensuring that it can meet the future needs of its customers.

With over 2,500 employees dedicated to research and development, Vital Materials has amassed more than 2,000 patents. The company also collaborates with leading research institutions and industry partners to extend beyond material development to process optimization and sustainability initiatives.

Recent R&D breakthroughs include Dr. Rajiv Pethe’s research on “LTC V2.” This proprietary transparent conductive oxide material offers superior performance metrics for solar and optoelectronic applications, including low processing temperatures and high transmission rates. “This material was developed through collaboration with our international partners and plays a pivotal role in identifying new applications and recommending its implementation across diverse industries,” states Dr. Pethe. This collaborative approach extends to joint research initiatives wherein Vital Materials partners with customers to co-develop new materials and applications. “Joint collaborations help us better understand customer needs and ensure successful integration of our products,” Dr. Pethe emphasizes. “It’s through these partnerships that we can push the boundaries of what’s possible.”

In all markets, collaboration with customers is a cornerstone of Vital Materials’ strategy. By working closely with clients, the company tailors its solutions to specific requirements, ensuring optimal performance and customer satisfaction.

Operating in over 20 countries with 49 offices worldwide, Vital Materials’ success is powered by a culture built on collaboration, innovation, and continuous learning. “The best ideas come from diverse perspectives working together,” Najera says. By fostering a culture of continuous improvement, Vital Materials ensures that its products and processes remain competitive in an ever-evolving market. The company’s international footprint enables it to tap into diverse markets and technologies, facilitating the development of advanced materials that meet the evolving needs of various industries.

Certainly, the advanced materials industry faces challenges such as material scarcity, supply chain volatility, and geopolitical factors. Vital Materials’ vertically integrated structure and recycling initiatives help mitigate these risks by ensuring a reliable supply of essential materials.

The team’s global operations also enable them to adapt to regional market demands and regulatory requirements. For example, facilities in Ohio and California serve as hubs for the North American market, ensuring timely delivery and compliance with local standards. Similarly, the company’s presence in Asia, Europe, and South America allows it to address the unique needs of customers in those regions.

“We emphasize that we are a global company with operations across many continents,” says Dr. Pethe. This distinction highlights the company’s diverse sourcing and production capabilities, which are critical to its ability to serve customers worldwide.

Looking ahead, Vital Materials aims to strengthen its leadership in rare materials and expand its production capacity. Sustainability remains a priority, with ongoing efforts to enhance recycling systems and reduce the company’s carbon footprint.

The company is also exploring opportunities to expand its presence in emerging markets and industries. With organizations specializing in functional materials, semiconductor applications, laser and infrared technologies, and thin film coatings, the company is well positioned to capitalize on the growth of electric vehicles and renewable energy technologies. By aligning its strategy with global trends, Vital Materials ensures that it remains at the forefront of the advanced materials industry.

As a leader in sustainability and advanced materials, Vital Materials is shaping the future of industries worldwide. By combining technical expertise with a commitment to environmental responsibility, the company is not only meeting today’s challenges but also paving the way for a more sustainable future. The company’s journey from a supplier in the minor metals industry to a global leader in advanced materials is a testament to its commitment to sustainability, innovation, and collaboration. Through its pioneering recycling technologies, robust R&D efforts, and global presence, the company has established itself as a trusted partner for industries such as semiconductors, renewable energy, advanced displays, and beyond.

“Our mission is to create value for our customers while contributing to a more sustainable world,” Dr. Pethe says. By staying true to this mission, Vital Materials is ensuring that it remains a driving force in the advanced materials industry for years to come.