Algonquin Mouldings has been on a spending spree. Based in Mirabel, Quebec, the firm has spent roughly $10 million over the past year on an automated rip and cross-cut line and a pair of scanners that utilize artificial intelligence (AI) to analyze data. The company’s goal is to boost productivity and efficiency while continuing to make beautiful wooden mouldings and wood components.

“Before this investment, the ripping, cross-cutting, and the planer were three separate operations. Now, we have put that all together in a big, automated line,” says President and Owner Sébastien Grenier proudly. “With that line, we were able to double our capacity.”

Even as the company embraces technology, Algonquin maintains an ecologically friendly ethos. “We are 100 percent green. Our product is made from renewable sources,” explains Grenier. The company buys lumber in different widths directly from sawmills “and then transforms everything in the plant,” he continues.

Key products range from kitchen cabinets and skirting boards to decorative mouldings, picture rails, and staircase components. More specialized goods include mouldings for caskets and playing tables. About 60 to 70 percent of the company’s work is done with maple, although it is also fond of alder, walnut, poplar, pine, cherry, and oak. As a business-to-business enterprise, Algonquin counts architectural millwork firms, finishing companies, and kitchen cabinet designers among its clients.

“We are exporters. We are based in Mirabel, Quebec, but only one or two percent of our sales are from Quebec. We have a lot going to the U.S. and western Canada; all the rest goes to Europe,” says Grenier. To this end, the company has Customs-Trade Partnership Against Terrorism (C-TPAT) certification. C-TPAT is a voluntary program, spearheaded by U.S. Customs and Border Protection, to streamline and secure the cross-border supply chain.

Algonquin Mouldings’ services are self-performed. “We don’t subcontract anything,” says Grenier, who points to the company’s multi-million-dollar investment in technology as evidence of its can-do spirit.

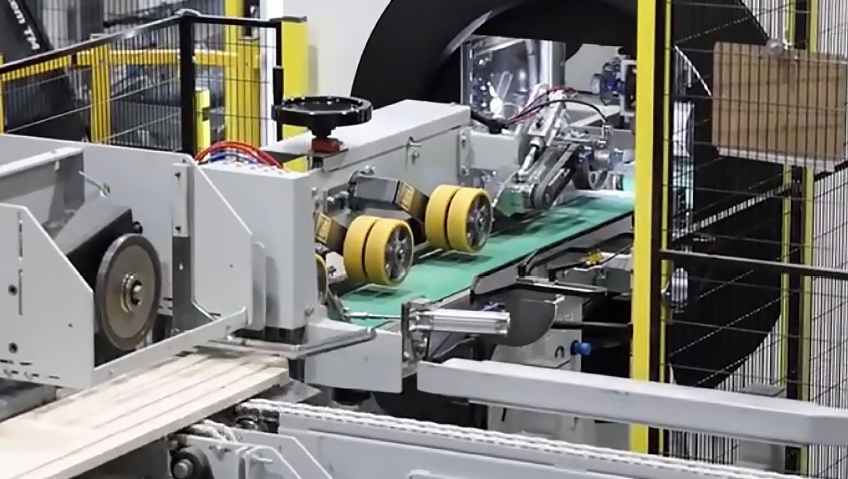

The automated rip and cross-cut line was purchased from System TM, a Danish equipment manufacturer that belongs to the Homag Group, the “world’s leading provider of integrated solutions for production in the woodworking industry and woodworking shops,” according to the Group. Algonquin’s scanners, which are used for ripping (making cuts that are parallel to the grain in the wood) and cross-cutting work, were made by Italian firm MiCROTEC.

Core elements of the System TM line include an Opti-Feed 6000—an automated infeed system that can automatically feed long workpieces. Opti-Feed 6000 offers high-capacity de-stacking capability, and frees a human operator from having to perform repetitive tasks.

Batches go through a planer that trims boards to ensure they all share a consistent thickness along their entire lengths, then are moved to a MiCROTEC Woodeye Rip scanner which scans wide lumber and transmits data to the rip saw. A conveyor then transports parts to a MiCROTEC Woodeye Crosscut scanner. Using lasers, sensors, and cameras, the scanner scrutinizes the wood surface for cracks, knots, discoloration, or any other type of defects. An inspection that might take a human operator minutes to accomplish takes only a split second with the cross-cut scanner, says Grenier. Once scanned, parts are cut by an TM Opti-Kap 5103 cross saw from System TM.

Both MiCROTEC scanners have AI capability. “Instead of having my technical people analyzing all the data, the AI does it for us,” Grenier explains. He compares the new rip and cross-cut line to a performance car and notes the uniqueness of using AI-powered scanners for woodcutting. “I got a letter from MiCROTEC, the Italian supplier, that said we were the first to buy his new model with AI in the entire lumber industry in the world. We were pretty proud of that.”

The system was so futuristic in fact, that it required special training for staff. “We have two engineers in charge of that new line. To make sure we were ready for it, I took my two engineers to the Massachusetts Institute of Technology to make sure we understood the AI,” Grenier tells us.

These purchases reflect the company’s mission “to become a 4.0 factory.” Also called the Fourth Industrial Revolution, Industry 4.0 refers to ‘smart’ manufacturing plants that make optimum use of computers, sensors, scanners, software, online networks, and other solutions.

Environmental responsibility is another key company value, and something Algonquin Mouldings takes very seriously. Algonquin is a zero-waste business and recovers virtually all of the wood fiber from the production process. The company has been certified by the Forest Stewardship Council (FSC), an organization that accredits companies in the lumber business that engage in sustainable sourcing. This practise ensures there is no long-term net loss of forests.

“Normally, when you think about the business of cutting trees, you don’t think of that as a green industry,” says Grenier. In fact, it is in the best interest of all operators in the wood sector to take a measured approach to sourcing and to encourage replanting. Otherwise, forests would be denuded, and business would dry up.

And there is another reason why Algonquin Mouldings emphasizes technological and green practices, and that is to attract younger workers. “The lumber industry is a pretty old industry and not the kind of [sector] that attracts the new skilled generation. Every new generation wants to go to Apple or Google, not into the lumber industry.” Young people in general are partial to both new technology and environmentalism, so embracing both “is the way we attract them and be ready for the future.”

Algonquin Mouldings was founded in the early 1990s by René Warnet and was family-owned until a few years ago, when it was purchased by Grenier. Like all companies, it has endured its share of challenges. A recent one has come in the form of steep interest rates, which have driven up the price of supplies. Due in part to these high interest rates, the company had to slim down from its usual complement of 65 to 70 workers (including office staff) to roughly 40 today. But at present, Grenier is looking to add new staff members. “Now with interest rates decreasing a bit, we see that business is [improving], so we are already starting to hire a little bit,” he shares.

Given the nature of what the company does, safety is paramount. Algonquin Mouldings has a safety committee that meets regularly and inspects the plant to take note of potential hazards. “I’ve been here 12 years, and I don’t remember the last accident,” Grenier says.

In terms of promotion, the company participates in trade shows and other industry events. Representatives recently visited China “because they are a huge buyer of Canadian maple. We went there to find new clients, make sure people know us,” explains Grenier.

Given that Algonquin Mouldings does not sell directly to the public, it is important that “the right businesses need to know us. We have a group of salespeople around the world… They are in charge of going to the right place and right business [to tell them] we can supply [wood products] at very competitive prices, especially with the new automation we have in the plant,” he continues.

For the time being, the company would rather focus on enhancing its existing core strengths than adding any new services or products. Grenier is, however, thinking about acquiring other companies to boost market reach.

Heading into the future, “The plan is to grow,” he states. “The goal is to just take a bigger part of the market in two ways: investments into productivity and also buying other plants.”