In today’s fast-paced manufacturing world, there’s a growing belief that simply adding robots or automated systems will solve production bottlenecks. But that’s not always the case. DeGeest Corporation, with decades of hands-on experience, understands that successful automation is not about adding robots and hoping for the best; instead, it’s about creating a carefully thought-out, step-by-step approach that prepares a company for technology adoption, ensures employees are ready to embrace it, and guarantees the long-term success of the system.

In a recent conversation with DeGeest Corporation, we explored the company’s proven path to automation—a method it has developed and refined over many years. The message is simple: don’t rush into automation. Start with small, manageable steps and prepare your team for the eventual introduction of more advanced technology.

Many companies approach DeGeest with a desire to immediately jump into automation by purchasing robots, believing that this alone will solve their production problems. “We’ve lived this experience,” said Derek DeGeest, company President. “We’ve seen companies rush to get a robot, thinking it will fix all their issues. But it doesn’t work that way.”

It’s not just about buying a robot and plugging it in. The integration of advanced technology, such as robotics, requires a systematic approach. DeGeest has successfully operated and used robots on a smaller scale and has seen how crucial it is to ensure that the entire system, workforce, and processes are ready for the robot. Otherwise, the technology can’t be utilized to its full potential.

Even for large companies, installing a robotic system takes time, with some projects taking up to 22 months before the robot is fully operational. DeGeest has learned that the key to automation success is taking it step by step, preparing the team, and eliminating as many variables as possible before the final investment in a robotic system is made.

DeGeest’s approach revolves around breaking down the automation process into manageable steps, ensuring the team is ready for the changes and the business can handle the shift. The company has created a roadmap for automation, where each step lays the groundwork for the next. This involves focusing on the variables and processes that can be improved without robots first. By improving these manual processes, companies not only prepare themselves for future automation, but they also start seeing immediate benefits. DeGeest points out that the key to successful automation lies in making the existing manual processes as repeatable and standardized as possible, and this can be done through various tools and technologies, even before robots come into play.

A big part of DeGeest’s strategy is preparing the workforce for automation. There’s often a fear among employees that robots will take over their jobs, but DeGeest emphasizes that this is far from the truth. When implemented correctly, automation enhances the work environment, and companies end up using robots as tools that make their jobs easier and more efficient.

DeGeest has seen firsthand the smiles that appear on employees’ faces once they understand that robots are there to help, not replace them. “It’s about eliminating the scare, the hesitation, the resistance,” Brad Ruppert, Director of Operations, explains. By preparing the workforce and involving them in the process, DeGeest ensures that automation is a welcome addition to the workplace.

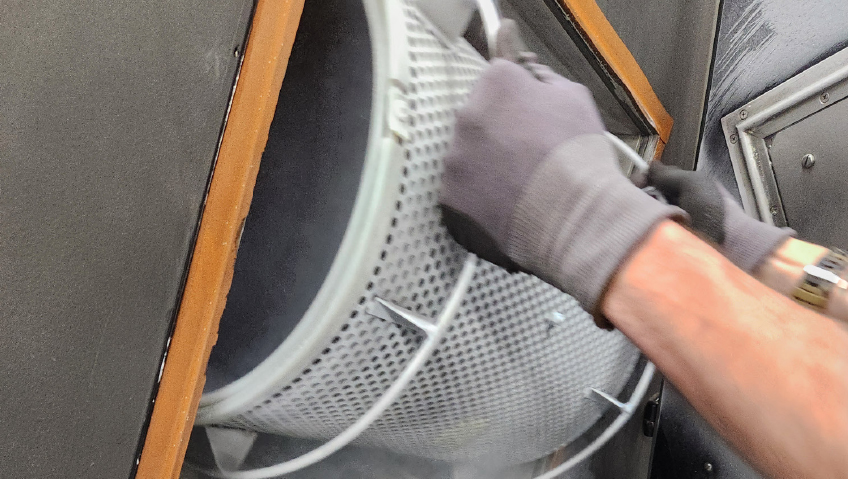

One of the groundbreaking innovations DeGeest brings to the table is self-learning robotic technology. Unlike traditional robots that follow pre-programmed paths, self-learning robots take things to the next level by adapting and learning from the actions of human operators. This technology, particularly useful in finishing applications, allows the robot to become an extension of the human operator, using their skills and experience to improve the process.

For example, in painting, the robot doesn’t just follow a programmed path; it learns the nuances of the operator’s techniques, every trigger pull, gun angle, and preset, and adapts to the variables in the system. This level of adaptability means that self-learning robots can handle more complex and variable tasks than traditional robots, making them more effective in real-world manufacturing environments. DeGeest has spent over 20 years developing and integrating solutions for finishing automation, and its self-learning robots are just one of the many innovations it offers. These robots provide companies with an easy-to-use solution that not only prepares them for future automation but also improves their current processes.

One of the cornerstones of DeGeest’s approach is eliminating variables in the manufacturing process. Automation works best when processes are standardized and repeatable, and DeGeest helps companies identify and eliminate variables that can be controlled, such as temperature, humidity, and compressed air. By doing this, the company ensures that manual processes are more consistent and efficient, which in turn makes it easier to introduce robots down the line.

The company’s patented technology, such as Polyfluid and NitroTherm, helps control these variables in both powder and liquid applications. These technologies provide immediate benefits by reducing costs, improving efficiency, and making the work easier for operators. By tackling these variables before introducing robots, companies can build a foundation for automation that is far more stable and reliable.

And DeGeest doesn’t just focus on finishing processes; the company has also developed a proven path to automation for welding. Many companies come to DeGeest with a need for welding robots, often driven by a shortage of skilled welders. However, instead of jumping straight into robotics, DeGeest offers a more measured approach.

Its partnership with Fronius has led to the development of WeldManager, a solution that helps standardize and control welding settings across manual welding cells. This ensures that even before robots are introduced, the welding process is consistent, controlled, and efficient. WeldManager helps adjust wire speed, amperage, and other settings in real time to ensure high-quality welds, regardless of operator technique.

Once these manual processes are optimized, companies can then introduce welding robots for higher-volume, repetitive parts. By starting with manual improvements and moving toward automation, DeGeest ensures that the transition is smooth and that the robots can perform at their best.

One of the most important aspects of DeGeest’s approach is its commitment to supporting customers throughout the automation journey. From the initial contact, DeGeest works closely with each customer to understand their specific needs, goals, and challenges. Once a system is installed, DeGeest provides extensive training to ensure that both production teams and management understand how to use the new technology.

But the support doesn’t stop there. DeGeest stays in close contact with customers, providing ongoing assistance and updates as needed. The team has developed systems that allow them to make adjustments to the automation process remotely, ensuring that customers are always getting the most out of their investment.

One of the things that sets DeGeest apart is its real-world experience. As a contract job shop that’s been in business for nearly 50 years, DeGeest lives the same challenges as its customers and uses the same automation solutions in its own production environment, so the team knows firsthand what works and what doesn’t. Its production showroom allows customers to see these solutions in action—not just in a test lab, but in real-world production settings. Whether it’s self-learning robots or the WeldManager system, DeGeest’s customers can see for themselves how these technologies can improve their processes.

At the end of the day, automation is about more than just adding robots to a production line; it’s about creating a plan, preparing your team, and taking measured steps to improve your processes. DeGeest Corporation’s proven path to automation offers companies a way to do just that.

By starting with small improvements, eliminating variables, and preparing the workforce, companies can set themselves up for long-term success. Whether it’s through self-learning robots, advanced welding technology, or innovative solutions for finishing applications, DeGeest is helping manufacturers across North America embrace automation in a way that’s sustainable, scalable, and effective. And that’s a message worth sharing.