Good companies change; great companies evolve. And few have adapted over the years like Schmalz, starting in 1910 as a razor blade business in Germany. Founder Johannes Schmalz was an entrepreneur far ahead of his time—how many businesses establish their own hydroelectric plant on a river to power their machinery?

Over the past 113 years, the company has re-invented itself, becoming even more successful. Leading the second generation, Artur Schmalz took the family-owned enterprise into transportation equipment used by Germany’s postal service and federal railway, delivering letters and luggage. A few years later, Schmalz began manufacturing stairways for passengers boarding aircraft. And in 1984, unique vacuum table technology developed by Dr. Kurt Schmalz led to the creation of vacuum systems, digitization to increase efficiencies, more staff, and unique products to meet the needs of Industry 4.0, like grippers for robots and bin-picking solutions.

Investing in the future

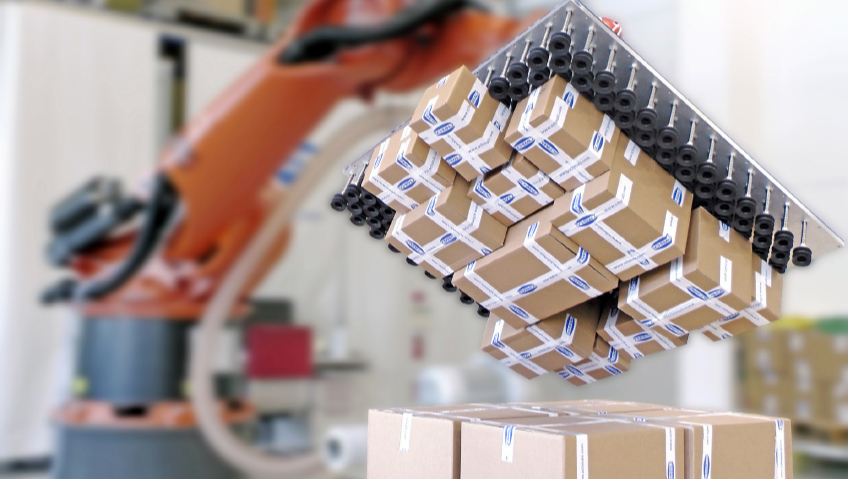

As the company states on its website, “Innovation is in our blood and is the driver for our growth tomorrow.” Active in state-of-the-art vacuum technologies for automation and robotics, Schmalz is also known globally for its vacuum clamping technologies, vacuum lifters and crane systems, digital services, and much more.

Many of the world’s best-known automotive, electronics, and furniture manufacturers count on Schmalz to lead the way in automation with its unique vacuum and ergonomic handling systems. From component and gripping systems to vacuum lifters, vacuum clamping solutions, and crane systems, Schmalz has the experience and technology necessary to make manufacturing faster, more efficient, safer, and less strenuous for workers.

In the face of its impressive growth—29 locations worldwide and over 1,800 employees and counting—North Carolina-headquartered Schmalz still upholds its family values, goals, and unrivalled customer service. A third-generation family business, Schmalz remains proud of its heritage. “When we look at our competitors, it’s usually a private equity firm, and they have a different mentality about how they see their businesses growing,” says Schmalz’s Michal Vigoda, Director of Vacuum Automation, who has been with the company for over 11 years. “Stable family ownership makes a difference.”

To support its ongoing commitment to innovation, Schmalz invests nine percent of its profits back into the company, money that is used for research, development, and the creation of dynamic new products. Even during the challenging COVID pandemic, when many companies struggled to stay afloat, Schmalz introduced 28 new products to the market while continuing to invest in the business. To date, the company has about 8,000 components to its credit, another key point of difference from others in the industry.

“We provide not only components that our customers can use, but also complete solutions,” says Vigoda, “and when we do that, we are there for the customer with integration and getting machines into operation, which many of our competitors are not always able to do. We have the engineering team available to do that.”

Recent acquisitions

Growing organically over the years, Schmalz recently shifted its strategy when it acquired British-based materials handling company Palamatic Ltd. in January 2022, and Swedish ergonomic lifting systems business Binar Handling AB and its four subsidiaries in Europe and Asia soon afterwards in March.

“Binar Handling perfectly complements the Schmalz portfolio for manual handling with its electric manipulators, crane booms, and various end effectors,” stated Dr. Kurt Schmalz, Managing Director and shareholder of J. Schmalz GmbH, in a media release. “In this way, we are significantly expanding our leading global position in ergonomic handling technology.”

Added the company in a statement: “With the acquisition of Binar Handling AB, Schmalz will offer solutions for sensitive balancing and handling in the future, for example, for applications in battery production or logistics.”

Introducing its ingenious ergonomic lifting and handling solutions to the market in 1979, Binar’s motto is “Beyond Gravity.” Over the years, Binar has provided products to customers in the pharmaceutical, food, chemical, industrial, aerospace, and automotive sectors. Through the acquisition, ergonomic products such as Binar Handling’s Quick-Lift Arm are now part of Schmalz Group.

Through its remarkable ergonomic lifting solutions, Binar Handling enables workers to use minimal hand strength to lift up to 600 kg (1,322 lb.) smoothly and safely, reducing repetitive strain injuries from moving heavy objects.

“It’s an intelligent servo hoist, so it gives you a little bit more functionality over a standard hoist,” says Schmalz’s National Sales Manager, Grant Welch. “It gives you precision control over where you are able to set limits, weigh products, and set safety aspects like anti-drop, and adds to the variety of product offerings that we have.” In charge of the manual handling equipment side of the business for the past eight years, Welch says Binar’s well-designed lifting solution technology is one of the best he’s seen.

By adding Binar and Palamatic, Schmalz further commits its skills, resources and products to customers worldwide. “It was a really good match for us,” states Vigoda. “We are known for very high-quality products, and Binar aligns particularly well with that reputation. It is really great product technology, and it filled a gap for us to expand more into mechanicals. And on the Palamatic side, they are known in the food industry for their stainless steel solutions, so it’s another good entry for us into that industry.”

Discussing the Palamatic acquisition, Dr. Schmalz said, “We were excited by the type of customer relationships Palamatic has with its business partners. We are convinced that together we will be able to offer Palamatic’s customers even greater added value in the future.”

Hands-on approach

Depending on the client, Schmalz’s material handling systems and solutions can come in when a new facility is being designed or after is it already built. Often clients realize workers manually picking up items like pieces of plywood, boxes, or beer kegs is inefficient and can result in injuries, and they look for solutions to solve these lifting challenges.

The company estimates that about 80 percent of clients purchase readily available standard lifter and crane systems for their needs. For the remaining 20 percent who have particular needs, Schmalz works with them to design and build custom-made tools meeting their exact specifications. The need for bespoke lifting systems exists especially in the automotive and aerospace industries, where higher levels of safety and specification have to be met. “This can include a particular kind of paint, powder coat, or hand controls,” explains Welch. “We are happy to work with them to accommodate whatever they need.”

And with four teams on the engineering side—Application Engineering, Design and Product Management, Inside Sales, and Technical Support—Schmalz supports its customers anywhere in the world.

With extensive training in the company’s product lines, application engineers are available to support technical applications and connect customers to regional sales managers, ensuring they have the right information and can recommend the best technology for their needs. “So besides product management, the application engineering team are going to be the ones on-hand to retain the technical knowledge, and can advise a range of customers from robot integrators and OEMs to resellers, distributors, and all the different types of clients we have,” says Welch.

Experiencing a rush of growth with customers in the wood and cabinet industries throughout the pandemic, the company is now seeing more clients in pharmaceuticals, aerospace, and automotive, especially the RV market, with more manufacturing being done in the United States. “The good thing about our product line is, we are in all of these different areas,” says Welch. “Palamatic, for instance, was an acquisition that opened us to more of the food and pharmaceutical-type areas that need really strict wash-down hygienic requirements—that was the gap that acquisition filled for us, so that’s been a new and exciting market for us to dig into.”

Continuing to receive awards for its work, including the company’s headquarters in Germany being recognized as a key employer, Schmalz continues growing and remains client-focused. “Everything is about the customer, and to me, what has been most rewarding is to bring these solutions to life, solve customer challenges, and continue on that path,” states Vigoda.

“There are many other people out there who we can help through material handling. Our physical lifting devices help people move product; they don’t feel at the end of their shift that their back hurts, or that they are physically injured. [Going forward,] Schmalz will bring even more products to the market and solve more technological challenges to help people.”