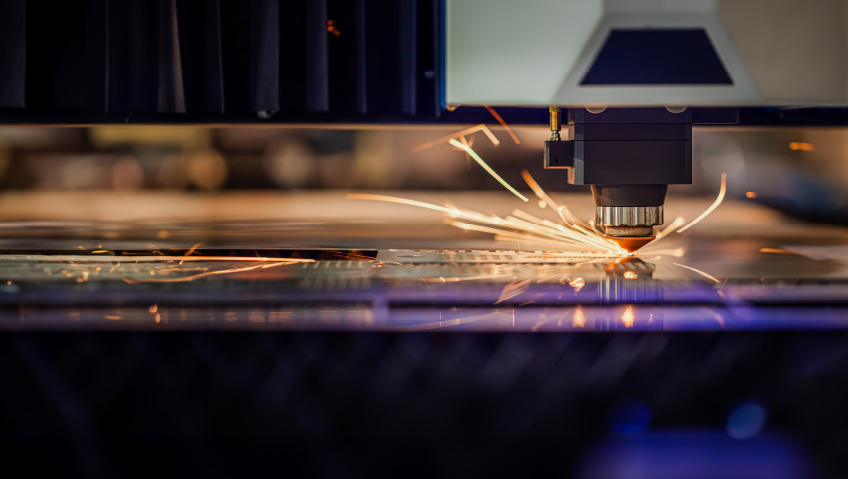

LasX Industries Inc. of St. Paul, Minnesota designs and manufactures patented industrial laser processing systems. Its lasers are used to mark, perforate, engrave, ablate, and cut everything from adhesives and plastics to textiles, vinyl, acrylics, and metallized films, primarily for clients in the manufacturing sector. The company has continued to stay on top of the industrial laser market with a new research and development lab, new equipment platforms, and an expanded service initiative.

LasX’s new PhotonX Lab, which opened in September 2024 at its headquarters, is intended to be a research and development hub for rapid, intelligent laser materials processing. To this end, the space boasts a variety of equipment including short-pulse infrared (IR) and ultraviolet (UV) lasers, high-power ultrashort pulse IR and green lasers, high-speed scanners, motion control, and low and high-powered carbon dioxide lasers, among other gear.

“PhotonX enables our engineers and customers to collaborate closely on next-generation applications across packaging, medical and life sciences, and aerospace and defense. The goal is simple: provide a space where new ideas can be proven quickly, evaluated rigorously, and scaled efficiently,” explains LasX President Ryan Falch.

The lab will enhance LasX’s ability to prototype, then test and validate various laser processes to reduce risk for customers, speed the passage of breakthrough products to market, and upgrade manufacturing performance, he adds.

There is no shortage of other developments beyond the PhotonX Lab. Probably the biggest single change since we last spoke in September 2023 for Manufacturing in Focus is “the expansion of our laser materials processing capabilities through the introduction of new LasX equipment platforms,” says Senior Development and Engineering Manager Ethan Dinauer, son of company Chief Executive Officer and Co-founder William Dinauer. “Over the past year, we have added near-IR, green, and UV laser technologies with nano-, pico-, and femtosecond pulse durations, delivering higher precision, faster processing speeds, and improved material compatibility,” he explains.

These changes have enabled LasX to deliver cleaner edges, tighter tolerances, more robust turnkey systems, and improved multi-material processing.

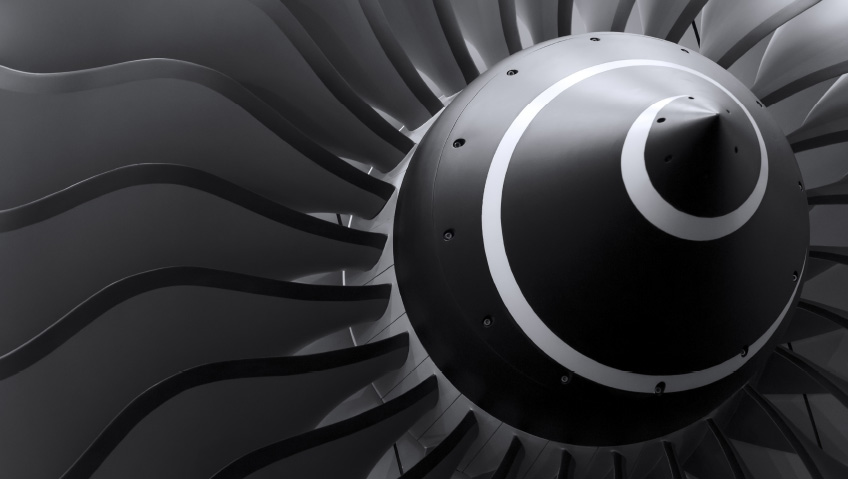

LasX’s new equipment platforms are designed to support three of the company’s main markets: fast-moving consumer goods (FMCG) and packaging—a category that includes everything from packaged foods and beverages to soap, shampoo, and toothpaste—medical and life sciences, and aerospace and defense.

While the company also serves the graphic arts, textiles, and automotive sectors, the three segments cited above “offer the highest growth rates… FMCG and packaging continues to represent a significant growth engine, driven by the demand for atmospheric control, easy-open features, mono-material packaging solutions, and direct-to-package laser marking,” Falch tells us.

For the packaging segment, he points to the new LaserSharp® Marking solution, unveiled in November 2024. Developed in partnership with consumer products giant Procter and Gamble, the LaserSharp Marking system offers multiple benefits: consistent, top-quality results even during high-speed production; design flexibility, even in areas that can be hard to reach; permanent, high-resolution surface marking; and a digital configuration that offers maximum agility in response to changing graphics and text.

LaserSharp Marking is also ecofriendly since it doesn’t use traditional shrink label and pressure-sensitive adhesive (PSA) materials, inks, or anything else typically utilized for label applications. LaserSharp Marking can thus reduce waste while bolstering clients’ sustainability initiatives, which is all the more reason why LasX is confident that the system will be a success.

“Within packaging, LaserSharp Marking is positioned to become one of the most dominant application categories in 2026, supported by major brand-owner initiatives around sustainable printing, variable data, and inkless marking,” Falch explains.

At the time of our previous feature, the company was gearing up for the launch of the Proton λ laser process controller (the second part of the product’s name refers to “Lambda,” a letter in the Greek alphabet). The controller has since been launched and proven to be highly successful, offering high-speed laser processing and superb resolution, and facilitating new raster applications (a type of pixel-based laser marking). Proton λ also provides fast laser marking (a process that places indelible images on materials) and can be incorporated into the company’s existing laser equipment lineup. “Since the introduction of the Proton λ controller, we have continued to strengthen our LaserSharp process control ecosystem,” Falch notes.

The company has also expanded “its portfolio of equipment platforms,” he continues. “These platforms serve as starting points for application-specific solutions across scoring, perforating, micro-machining, laser marking, and surface modification.”

These achievements are somewhat par for the course for a company that has been ahead of the curve for decades. LasX was founded in 1998 to fill a perceived gap in the manufacturing sector: “the lack of a flexible modular option for laser material processing” as the company’s website puts it. A year after LasX launched, it began to design and build industrial laser processing modules (LPMs), which are critical for processing flexible materials. LasX’s LaserSharp® Processing Module is key to its materials processing capability, along with intuitive LightGuide operator software.

Recent “software enhancements in LightGuide have improved recipe control, diagnostics, and integration with automation and vision systems,” Falch points out.

In 2022, LasX released a machine platform called FreshFocus, a pioneering laser system that perforated and laser scored packaging to make it both breathable and easy to open. Breathable food packaging has tiny holes that allow in oxygen, extending shelf life.

In 2012, LasX established a life sciences group with ISO 13485 certification. The group has full-service contract development and manufacturing organization, currently focused on applications involving thin-film laser converting and microfluidic technology.

Earlier this year, LasX announced it had made significant microfluidic modifications to biosensor electrodes produced by global medical equipment manufacturer, Linxens Healthcare. The modifications were intended to “enhance the functionality of our electrodes, enabling real-time continuous blood parameter measurements and expanding diagnostic possibilities,” explained Linxens in an article posted on the LasX website.

And LasX’s European branch, founded in 2016 and based in Germany, continues to thrive. “LasX has strengthened its European engagement by adding Clive Jacobs, Director of Global Strategic Partnerships, to lead key account development across the region,” says William Dinauer. “Clive works closely with our European Solutions Engineer, Hendrik Kleinfeldt, to support both the FMCG and packaging markets with a particular focus on our LaserSharp Marking initiatives.”

For LasX, leading-edge solutions are only part of the equation. The company has long emphasized the importance of excellent customer service. Among other measures, its ClearCut® service program offers a lifetime of enhanced customer support in the form of training, remote assistance, discounts on labor and parts, equipment performance checks, and upgrades to software. The benefits of ClearCut include optimized performance, avoiding unpleasant surprises through preventive maintenance, accelerated training, software upgrades, and a comprehensive maintenance plan.

Plans are afoot to make ClearCut even bigger and better. “Soon, we intend to expand the ClearCut program to offer on-site process support to help customers optimize recipes, validate materials, and accelerate production readiness and on-site and virtual operator training, allowing teams to become fully proficient faster,” says Falch.

LasX also offers a global solutions team made up of experts who assist clients in various ways. Sometimes, this assistance is focused on a specific project involving laser material processing or new manufacturing methods. Other times, the collaboration is broader-based and involves large firms that need outside help because their own internal development teams do not have the laser expertise.

The team is highly active and on an expanded mission. “The team now operates within a more focused execution model, aligning resources to our primary markets and adding new business development personnel to ensure we remain deeply connected to customer needs,” says Ethan Dinauer. “The global solutions team strengthens responsiveness, improves cross-functional collaboration, and ensures that every customer benefits from experts who understand both their industry and their long-term production goals.”

This strong emphasis on customer support reflects the company’s determination to be more than just an industrial laser systems provider. The idea is to provide solutions, which means offering as much assistance as needed. This inclusive, far-reaching approach has helped LasX stand out from competitors.

“LasX is unique because our equipment and contract manufacturing solutions combine intelligent laser processing, turnkey automation, and precision engineering into a single, performance-guaranteed ecosystem,” states William Dinauer. “The LaserSharp Processing Module and fully integrated LasX equipment platforms are engineered around each customer’s exact application. This includes process development, system design, automated material handling, vision/SPC (statistical process control), and lifecycle support, all delivered with the high reliability required for demanding commercial production environments.” It’s a formula that has served the company well since the beginning and will continue to fuel innovations in high-performance laser materials processing.