As technology advances and Industry 4.0 becomes the norm, are manufacturers and workers ready to meet the needs of the future?

As time and technology advance, manufacturing’s reputation for the ‘3Ds’—Dirty, Dull, and Dangerous—is rapidly becoming a relic of the past. Over a century ago, working 12 hours a day, seven days a week wasn’t unusual in many North American factories. And to say children were exploited is an understatement; instead of being schooled, kids as young as six worked in factories, earning far less than their adult counterparts. Despite their tender age, youngsters were equally exposed to unsafe machinery, poor lighting, and smoke-filled, overcrowded factories.

These poor working conditions persisted for decades until U.S. President Franklin D. Roosevelt’s government brought in the Fair Labor Standards Act of 1938 (FLSA). Along with fostering the right to a minimum wage and time-and-a-half overtime for workers putting in over 40 hours per week, the FLSA brought in child labour provisions governing children under age 16, and civil penalties for child labour violations.

Sadly, there have been countless workplace injuries and disasters over the years. One of the most infamous remains the Triangle Shirtwaist Factory fire of 1911. Engulfing New York’s Triangle Shirtwaist garment factory, the inferno claimed the lives of 123 women and girls and 23 men, most of them recent, uneducated immigrants. Since the factory doors were locked to prevent theft and unauthorized breaks, workers died from the fire or smoke inhalation, while others jumped to their deaths. The tragedy accelerated the growth of labour unions such as the International Ladies’ Garment Workers’ Union (ILGWU), which had been formed in 1900.

Changing for the better

In the United States, manufacturing accounts for approximately 12 percent of gross domestic product (GDP); in Canada, manufacturing generates about 9.5 percent of the GDP. Worldwide, manufacturing is responsible for millions of jobs. From pens and parkas to computers, cell phones, and cars, manufactured goods are an essential part of our everyday lives.

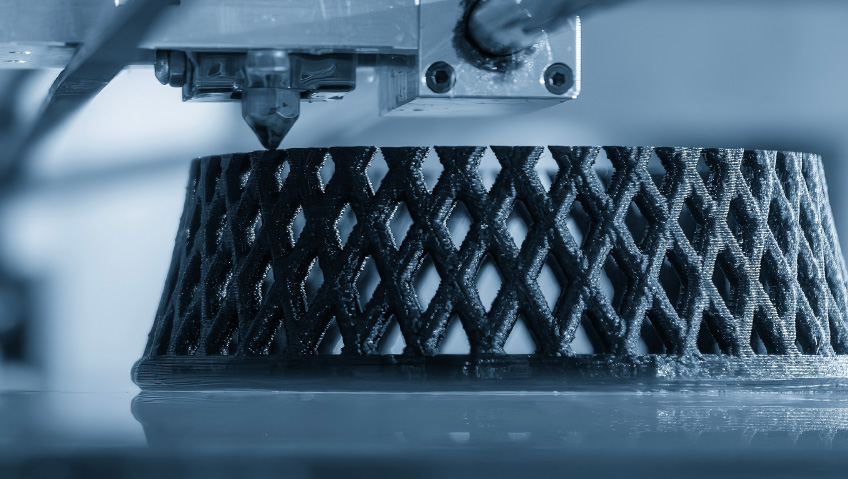

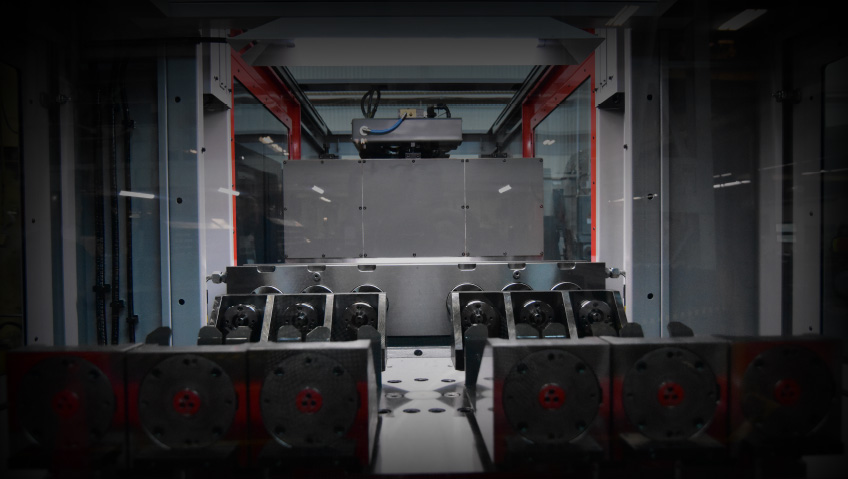

As our need for goods grows and diversifies, so does the manufacturing sector. In the United States and Canada, processes are rapidly evolving, with many companies embracing the Fourth Industrial Revolution, better known as 4IR or Industry 4.0. Although many factories still have time-tested machinery like lathes, injection molding machines, presses, grinders, and mixers, these are being joined by 3D printers, industrial robots, precision lasers, programmable machines, advanced robotics, Internet of Things (IoT)-enabled devices, artificial intelligence (AI), machine-to-machine (M2M) communication, and other smart technologies.

The result of such technologies is greater accuracy and fewer errors, machines able to produce products at faster speeds and greater volume, enhanced safety, and self-monitoring capabilities. Eager to increase output and lower costs, manufacturers are investing in the latest technologies, and according to estimates, the global industrial machinery market is positioned to increase from USD 592.4 billion in 2022 to USD 1,041.6 billion by 2032.

With Industry 5.0 on the not-so-distant horizon, savvy manufacturers are preparing their facilities for this upcoming technology and for the need for trained workers to handle the demands that the next generation of manufacturing will bring. According to the European Commission—which prioritizes the European Union (EU) in building “a sustainable, digital and inclusive future” through seven priorities, such as competitiveness and security and defense—Industry 5.0 will be a key driver in the EU’s future success. While complementing Industry 4.0, Industry 5.0 will play “an active role in providing solutions to challenges for society including the preservation of resources, climate change and social stability.” It will need to empower workers, attract the best talent, and address “the evolving skills and training needs of employees.”

Expectations placed on manufacturers today, such as recycling, minimizing waste, preserving natural resources, and adopting circular production models, will keep increasing. And to remain competitive, manufacturers will need workers who are able to balance these considerations with tomorrow’s technology. “Industry 5.0 envisions a future where industries go beyond just efficiency and productivity, focusing on worker well-being and using technology for broader prosperity while respecting planetary limits,” states the European Commission. “It places human values at the core of production, driving the digital and green transitions essential for Europe’s long-term success.”

To be successful, manufacturers will need skilled staff who are able to bridge human and machine intelligence. Artificial Intelligence, after all, is only as accurate as the data it receives.

Manufacturing: the next generation

In November 2023, Canadian Manufacturers & Exporters (CME) released Manufacturing Canada’s Future. The 26-page report provides important information on key areas, including the need to expand and upskill the country’s manufacturing workforce. Some of the issues manufacturing are facing include red tape, regulatory barriers, trade barriers, a lack of incentives in investing “in productivity-enhancing machinery and equipment,” and the ongoing skills shortage.

For the nation’s manufacturing sector to remain competitive, the report suggests manufacturers work with all levels of government to devise strategies for advanced manufacturing. The four key areas are: Expanding and upskilling Canada’s manufacturing workforce; Stimulating innovation, investment, and the adoption of advanced manufacturing technologies; Encouraging domestic manufacturing production, and value-added exports; and Speeding up and expanding clean technology incentives to help manufacturers adapt to and advance Canada’s climate change plan. According to the CME, implementing these recommendations will bring benefits such as increased productivity, emission reductions, greater production, and securing “manufacturing’s rightful place as a key driver of Canada’s economic growth and prosperity.”

Manufacturing is in a state of transformation, and to be successful, companies must embrace technology and ensure the 3Ds stay in the past. The challenges ahead—from skills shortages to sustainability pressures—are significant, but they are also opportunities for reinvention. By investing in training, adopting advanced technologies, and collaborating with governments and industry associations, manufacturers can strengthen their competitiveness while supporting environmental and social goals.

What began as an industry defined by long hours and unsafe conditions is steadily evolving into one that values innovation, efficiency, and human well-being. As Industry 4.0 matures and Industry 5.0 approaches, the future of manufacturing will not only be about what the machines can do; it will be about how they do it, with people and technology working together to create a safer, smarter, and more sustainable world.