Additive manufacturing (AM)—more commonly known as 3D printing—is a rapidly growing technology serving both consumer and professional sectors. For the first time, end users can design and manufacture products at home with the right materials and schematics, while both new and established businesses are finding novel ways to mass-produce products and expedite manufacturing. These applications are only the tip of the iceberg, and they’re not without challenges as 3D printing continues to take off.

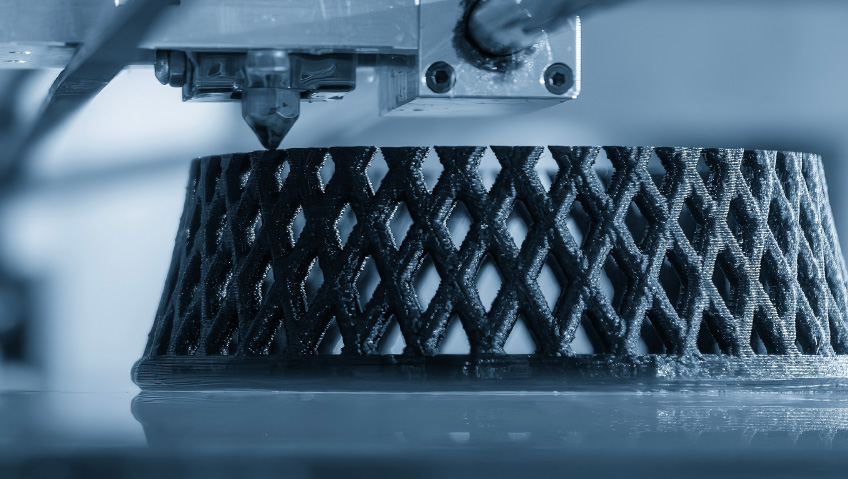

Many sectors have been—and continue to be—transformed by what additive manufacturing offers the modern workspace. In a piece for Engineering.com, Ian Wright says the aerospace industry has adopted 3D printing with considerable intensity. Advancements in FFF (fused filament fabrication) materials, such as carbon fiber–infused filaments, have paid off in the creation of drones used for activities like photography, surveillance, prototyping, and more.

Wright notes that research shows composite filaments can improve lightweight components, delivering higher durability and performance for UAVs (unmanned aerial vehicles). He adds that other industries, like automotive, may see greater adoption in the future as electric vehicles become more commonplace globally. “For example, electric powertrain components that need fluid-based thermal management can benefit from conformal cooling channels that can only be made using metal AM,” says Wright.

Secondary factors are also accelerating adoption across myriad sectors. In a piece on ongoing trends for 3D Printing Industry, Michael Petch says the growing prevalence of AI and machine learning will expand 3D printing’s footprint. Experts polled by Petch posit that automation will optimize design, production, and post-processing, and enable monitoring systems that enhance quality control and certification while helping prevent failure. Many sectors will also benefit from lighter, higher-performing parts.

Petch says that 2025 is a big year for moving 3D printing further into industrialization and mass production. Materials integral to the process are also driving this shift, including advanced metal alloys like titanium and aluminum, fiber composites, and more cost-effective pellet-based extrusion. There are also calls within the industry to develop more environmentally conscious materials and processes to mitigate additive manufacturing’s operational footprint.

Currently, the up-and-coming additive manufacturing industry is seeing moves that encourage both interest and caution. Jake Volcsko, writing for Advanced Manufacturing, says consolidation is an ongoing theme among AM companies. “Consolidation fosters greater collaboration and could help pave the way for the standardization of processes, materials and procedures, as well as identify areas in which AM offers distinct advantages,” says Volcsko. Consolidation is primarily occurring among American and European manufacturers, while many companies in China are expanding into Western markets to keep up with competition.

It isn’t all boom for additive manufacturing, though. Madeleine P, in a piece for 3D Natives, says 2024 brought many negative developments that created a downcast atmosphere (such as bankruptcies and failed mergers). Q3 2024 saw a sales decrease of about 25 percent from the previous year, but growth of around 14 percent was still predicted for the sector. Companies worldwide saw greater investment as the year progressed, which suggests greater staying power alongside growing use of 3D printing in advanced fields like medicine. However, ongoing issues like U.S. tariffs may influence how much manufacturers are able to grow.

Other factors have slowed momentum and prompted caution across the space. In 2024, 3D printer manufacturer Stratasys filed two lawsuits against Bambu Lab for patent infringement. Stratasys alleges that Bambu Lab knowingly infringed several of its patents in printer designs, which could be especially damaging for Bambu Lab as it enters a growth phase. This legal action is being considered a watershed moment in the 3D printing sector and, along with other ongoing cases, may set legal precedent for decades.

Many factors are still driving growth in 3D printing, writes Melina Bluhm for Replique. Other trends include large-format printing, which is allowing sectors like construction and energy to benefit from parts and goods beyond the scope of typical at-home or office printing. “As 3D printing steadily marches toward industrialization, 2025 marks the year it fully integrates into the broader manufacturing ecosystem,” says Bluhm. 3D printing is fast becoming a vital tool for manufacturers.

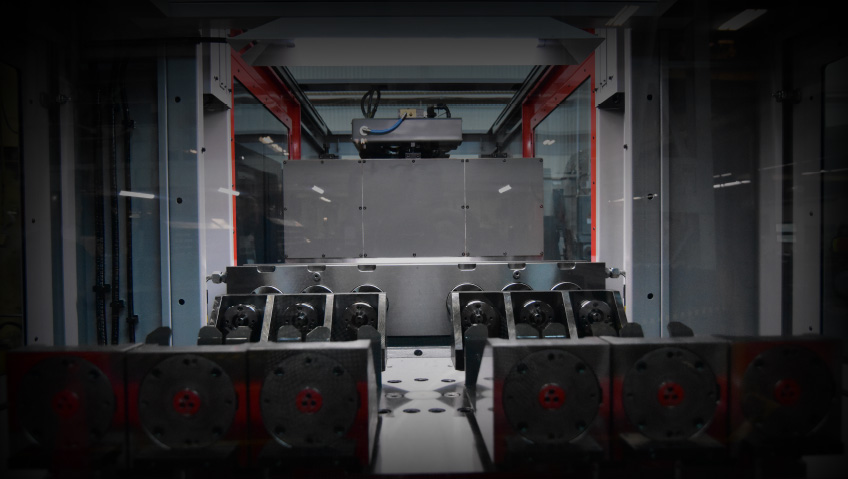

One way 3D printing is taking greater hold across countries is through microfactories. A microfactory is a smaller, highly specialized production facility that provides an end-to-end solution for an entire product. These enable shorter supply chains, quicker post-release iterations, and, importantly, a much more localized focus than traditional factory setups. Microfactories are often highly automated to prioritize speed and efficiency.

In a report for CNBC, Shafi Musaddique says 3D printing microfactories are even enabling some manufacturers to become more ecologically sustainable. For example, the UNSW Sustainable Materials Research & Technology Centre (SMaRT) builds plastic filaments made from 100 percent waste plastics, often locally sourced. Their goal is to deliver automated, locally focused production tailored to customer needs, alongside environmentally friendly practices.

Petch adds that, in the global supply chain, decentralized, regional manufacturing hubs for resilient supply chains will make production more efficient and secure. “The trend toward regionalized manufacturing hubs is gaining momentum to reduce supply chain vulnerabilities as geopolitical manoeuvring creates uncertainty around trade tariffs,” he writes. Businesses are reacting differently to ongoing tariffs, and microfactories may help mitigate negative effects that could stunt development of the additive manufacturing segment.

True to the DIY nature of additive manufacturing, microfactories are a way for 3D printing to continually innovate on the modern manufacturing process. AM’s relationship with other buzzworthy technologies like AI suggests it will keep attracting attention by staying close to the cutting edge. Despite setbacks, its continued growth shows it’s here to stay and will soon offer even more to newcomers to the field.