For four decades, Abacus Automation has been at the forefront of the automation industry, designing and building custom machinery that transforms the way businesses operate. What began as a small operation in a garage has evolved into a thriving company with a 30,000-square-foot facility, serving industries worldwide.

Abacus Automation was founded in 1982 by Richard “Dixie” Zens and Donald Alvarado, who turned a setback into an opportunity. After being downsized from their previous employment, they started Abacus Engineering Company, working out of their basements and building a solid reputation for high-performance automation and cost-effective design of manufacturing processes. They quickly moved into an incubator site for new businesses and then purchased a small building in the town of Bennington, Vermont. By 1999, they outgrew that building and built the existing location.

Now, with Scott Elithorpe, President, and partner Mike Perra at the helm, the company is poised for continued growth. “My partner and I have a long history here at Abacus,” says Elithorpe. “We plan to keep the company rolling for many years.” Their leadership ensures that the company continues to thrive by adapting to industry advancements while maintaining the core principles of innovation and customer-focused service.

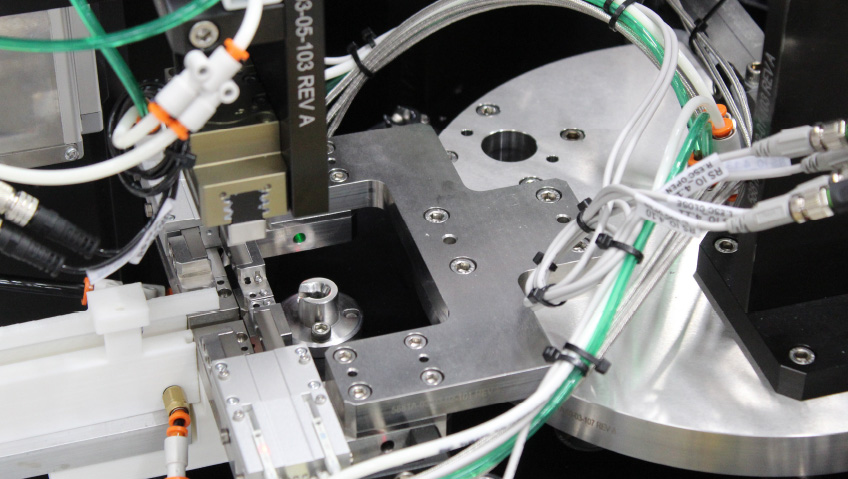

What sets Abacus Automation apart is its commitment to custom-built solutions, designed entirely in-house from start to finish. Unlike companies that offer off-the-shelf products, Abacus works closely with customers to create machines tailored to their specific needs. “We build amazing machines from scratch,” says Elithorpe. “That transforms our customers’ ability to meet the needs of their markets, right from research and development through product testing, assembly, and packaging.”

Abacus Automation specializes in part handling and assembly, ensuring high throughput, eliminating ergonomic issues, and removing human error through automated handling and assembly systems. The company also focuses on highly adaptable flexible automation, offering tailored solutions to unique manufacturing challenges. With years of experience in building turnkey solutions, Abacus has the expertise to create efficient, streamlined systems that integrate seamlessly into existing operations.

Production quality control is another key area of expertise. Abacus incorporates multiple features to ensure a quality product, with every motion sensed, every critical process measured, and every operation sequence optimized. By integrating fast product changeover capabilities, Abacus allows customers to switch between different product styles with minimal downtime. This flexibility enables multiple products to run on a single production line, increasing efficiency and adaptability.

Efficient conveying and palletizing keep production running smoothly to meet customer demand. Abacus provides automated transfer systems and downstream packaging solutions that streamline manufacturing processes, helping businesses improve productivity and reduce costs. And every machine Abacus creates is built to last, a fact reinforced by the company’s high rate of repeat customers and word-of-mouth referrals.

“Our equipment is very high quality and well-supported, which is evidenced by the bulk of our business coming from repeat customers,” shares Elithorpe. “We design everything from scratch, making each project a unique build, but we also channel experience from past projects to ensure successful outcomes.”

Abacus Automation thrives not just because of its technology, but because of its people. With a team of over 40 employees, ranging from industry veterans to eager new talent, the company has cultivated a family-like atmosphere that fosters creativity and collaboration. Employees take pride in their work, knowing they contribute to meaningful and innovative automation solutions used worldwide.

“Everyone here is an essential part of the team and ensures we’re successful with our machine builds,” says Elithorpe. “A lot of us have been together for many years, which turns into a real family culture. We all have kids and grandkids of the same age, so we spend a fair amount of time together outside of work as well.”

This camaraderie translates directly into the company’s innovative approach. “A lot of creativity goes into our designs. We often have brainstorming sessions, and you never know where a great idea will come from; it’s not always from the person designing the machine. Sometimes, it’s someone who saw a process in a factory somewhere and can bring that insight to the team.”

Abacus Automation has built custom solutions for a diverse range of industries, including medical, aerospace, military, consumer, cosmetic, food, manufacturing, automotive, and many more. The company’s machines are in operation worldwide, from the United States to Europe, China, and the Dominican Republic.

“Some of our latest machines include one for a local business that produces critical parts for the aerospace industry and another for a manufacturer of medical devices used in hospitals and ambulances,” Elithorpe shares. “It makes you feel good when you’re making a machine that goes into something important like that.”

The company also focuses on developing automation that improves worker safety by reducing exposure to hazardous tasks. “A major challenge in manufacturing is dealing with processes that are hazardous for workers,” says Elithorpe. “We’ve developed an attitude that we’re not trying to replace humans with machines but rather move people away from tasks that could cause them harm. Let the machinery do the difficult work and free up the people for better work.”

Abacus Automation has consistently evolved to meet the demands of emerging industries. In recent years, the company has expanded into renewable energy, food production, and advanced material processing. These sectors require specialized automation solutions, and Abacus has leveraged its expertise to develop systems that increase efficiency and reduce waste.

“Our flexibility allows us to venture into new industries,” Elithorpe explains. “For instance, in the renewable energy sector, we’ve been involved in building automation for solar panel manufacturing. These machines help streamline production, making solar energy more accessible.” By broadening its reach, Abacus continues to adapt to the changing industrial landscape, ensuring its relevance for decades to come.

As automation technology evolves, Abacus Automation remains committed to staying ahead of the curve. One major trend is the shift from cam-driven equipment to electronically controlled and programmable systems. “Couple this with more vision systems and robotics, and it makes the equipment easier to adjust to customer needs. A lot of our customers want machines that can work for various product sizes and configurations instead of just one select product. The electronic route is more adaptable than a hard cam-driven machine.”

Another growing trend is the integration of automation with digital networks. “We see more customers who want to tie our machines into their networks so they can monitor them remotely,” Elithorpe says. “I suspect that data collection requirements will start increasing as well.”

The company is also exploring the use of artificial intelligence (AI) in automation. “AI-driven vision systems and predictive maintenance are game changers,” he adds. “By incorporating AI, we can create smarter machines that detect potential issues before they cause downtime. This helps our customers maintain efficiency and reduce costs.”

As Abacus Automation enters its fifth decade, the company remains committed to innovation while maintaining its personal approach to customer service. “What I believe sets us apart is our service,” Elithorpe states. “If a customer has an issue with a machine, they can call up and talk to the people who built it. We’re small enough to handle the small jobs but big enough to take on the large ones. Either way, every customer gets personal attention.”

With its commitment to quality, innovation, and customer satisfaction, Abacus Automation is set up for continued success. Whether developing groundbreaking solutions for new industries or refining existing processes, the company’s dedication ensures its impact on automation will endure for many years to come.