The surname in Williams Fire & Hazard Control refers to Les & Dwight Williams, who launched the business in 1980 as a response company for the oil and gas industry. Beforehand, it had partnered with Boots & Coots, an international well control company, wherein Williams Fire & Hazard Control handled the flammable liquids division. The company eventually became independent in 1990 and separated from its partnership with Boots & Coots, carving out its current identity in the marketplace.

Williams underwent several more foundational transitions including three acquisitions in the span of 13 years until 2023 when, upon the verge of closing, an internal team headed by Lindsey Boren (Director of Global Sales and Marketing), Eric LaVergne (Director of R&D & Business Development), and Justin Wright (Director of Manufacturing and Global Response), drove an initiative to regain independence with investor support. As of January 1, 2024, Williams Fire & Hazard Control is once again a Texas-owned business and recently celebrated its first year as such.

Eric LaVergne explains that Williams has always been at the forefront of equipment design, a pursuit that was born out of necessity as a fire response business. For instance, Les Williams invented the company’s signature Hydro-Foam technology in 1983, which has helped to extinguish large-volume fires. The company has since designed, utilized, and sold equipment systems that flow in excess of 14,000 GPM (gallons per minute) into domestic and international markets.

LaVergne says that, upon its founding, protein-based foams were still in prolific use across the oil and gas industry, with many companies still using them while also gradually changing to AFFF. Now, industry is seeing yet another transition to non-fluorinated foam concentrates.

Throughout its history, the Williams team has navigated numerous industry shifts, consistently positioning itself at the forefront of innovation and leading through performance and response expertise. LaVergne notes that, in the earlier days of the industry, large-scale incidents were far more common, with several major events across the sector leading to the development of OSHA’s Process Safety Management Standard in 1992. With its publication, industry-wide processes, including best practices used by Williams Fire & Hazard Control, became more standardized, contributing to a significant reduction in incidents worldwide.

Over the years, Williams Fire & Hazard Control has also maintained an impressive safety record, thanks in no small part to employee involvement in technical response, safety measures, and ever evolving industry standards. Today, the company is proud of its excellent safety record that includes a decade without an OSHA lost time incident and eight years since its last OSHA recordable injury. “Our mindset and motto at our site is, ‘Performance and expertise drive a safe environment,’” LaVergne says.

That very motto is also indicative of the company’s tight-knit internal culture. Lindsey Boren says that Williams has always had a familial atmosphere, something she noticed immediately upon arriving in 2008. Currently, everyone is very happy with being an independent company after years of corporate ownership, with several former employees returning to the company upon its reclaimed independence. “We have witnessed a passion around this brand that results in long tenure by our employees and clientele, and with a commitment to our collective success, it’s easy to see why.”

Williams Fire & Hazard Control maintains strong industry relationships around the world. As Boren puts it, “It’s best to build strong relationships in advance”—acknowledged by the longstanding connections the company has with many of the organizations it supports during emergencies. In such a close-knit industry, it’s rare to find someone who hasn’t worked with Williams in some capacity. The company also collaborates with international partners and distributors who bring its products and expertise to the EMEA (Europe, the Middle East, and Africa) and APAC (Asia-Pacific) regions. Maintaining these relationships is essential, ensuring that the Williams methodologies and signature trust are upheld across the globe.

Another hallmark of Williams’ market approach is its focus on building long-term client relationships. When it comes to keeping clients first, Williams will always provide a good product at a good price. Dedication to service also means that, in this relationship-focused business, industry can call Williams at all hours, trusting the team to meet their needs. Boren says that if one doesn’t approach these situations totally committed, it’s impossible to maintain enduring relationships.

In all scenarios, Williams pulls from all different departments for emergency response to benefit its customers, says Boren. Thus far, the team has been involved in more than 280 major industrial emergency responses—which doesn’t include the rental of equipment, technical assistance over the phone, or post-incident assessments. “Loyalty from our clients over the past 45 years has been incredible,” and as Boren says, “We wouldn’t be successful without their support.”

After its first year under new management, Boren says that everything went beyond expectation, while still leaving room for improvement.

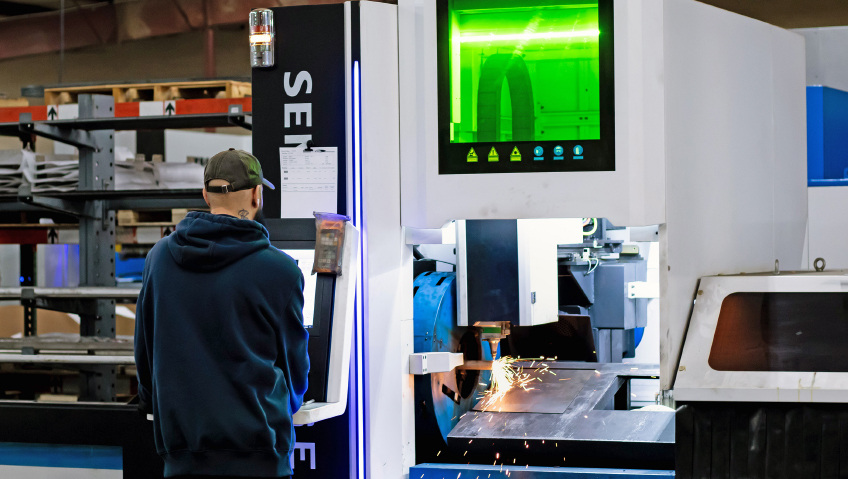

As a business that evolved by finding and filling market needs, Williams has embraced innovation since its earliest days and will continue to do so. One recent innovation relates to its Hot Shot apparatus foam systems, which will deliver a third-generation upgrade this year. A new company website has been launched that enhances market engagement around technical response practices and product applications, while a new mobile app upgrade helps calculate friction loss, foam applications, and k-factor performance in the field—all essential elements in fire hydraulics. Adding to its end-to-end manufacturing capabilities, Williams is also investing in new and additional equipment to enhance production lead times. The company has also bolstered its R&D Team who maintain a healthy pipeline of groundbreaking product developments and improvements.

With incident control and extinguishment as its benchmark, Williams continues to scrutinize foam formulations closely and personally to assure that performance in the field and compatibility with its equipment are driving factors in its foam of choice. As a response company, Williams seeks the best performing products in the market for its own response team—and for its clients. “We have always insisted on effective performance over minimum compliance standards,” says Justin Wright, Director of Operations.

Firefighting foams are a linchpin in a responder’s arsenal. As industry faces challenges around environmental standards affecting foam formulations, Williams is constantly driving a well-informed, experience-based approach to best-in-class foam practices to the industry at large. However, a mounting concern facing the industry is retirement of those with extensive experience. As industry continues its safe practices and incidents have decreased, transfer of knowledge to the next generation of responders with less experience is paramount.

Since last January, Williams continues to grow as it satisfies market demand. Williams plans to expand its operation both in manufacturing and customer support by hiring additional personnel. Other goals include shorter lead times, improving internal processes, and leveraging industrial relationships to improve response times on calls.

Above all, Boren says that Williams will remain present in the market. “We are confident that our skill set, our history of experience, and our continued innovation will benefit a broader market of industry clients with their greatest emergency response needs.”