Although Lean Manufacturing Products LLC (LEAN) may be a younger company at less than a decade old, it has already made great strides in the manufacturing industry. The company was founded as a spin-off from a legacy-minded contract manufacturer named Wisconsin Metal Parts (WMP), a long-running business with a considerable history of high-quality metalworking, precision fabrication, and related manufacturing. As WMP itself grew larger, it saw the need to implement solutions for optimizing storage, space, and efficiency, which LEAN was established to address.

Since 2016, LEAN has made it its mission to develop innovative and customizable solutions to enhance productivity and reduce waste in manufacturing environments. This vision has enabled the company to become the distinct leader in efficiency and sustainability in the United States, as well as to redefine simplicity itself by pursuing safe and efficient workspaces.

The suite of offerings from LEAN includes storage systems, returnable cartridges, carts, kitting solutions, and racks of varying size and capacities made for manufacturing storage facilities, as well as WIP (work in progress) and downstream operation solutions. These products serve to store materials like sheet metal as well as long stock materials (i.e. steel tubes, angle iron, aluminum extrusions), all of which need specific handling and care to be managed effectively in a facility storage space.

Company President Jake Erschen, the son of WMP founder Dan Erschen, grew up around the metal manufacturing industry and got hooked on it following a career change after college. After designing and establishing a solution and business model to reduce the time spent handling material, Jake applied it to the then-nascent LEAN Manufacturing Products and has since seen the business expand its operations into practically every American state. “We work hard to show customers the shortest ROI [return on investment] period for what we offer,” he says.

The business has drawn on the skill of many talented and capable workers in its short history. Team members like Production Manager Jordan Meyer and Sales Lead Steve Drida say that they were initially drawn to LEAN’s product offering as well as what the company offers the manufacturing industry. Meyer and Drida are proud to be part of such a forward-thinking and innovative operation and appreciate getting in on the ground floor with LEAN when it was first established; they were able to see the team’s efforts having a direct impact right away.

LEAN further stands out in its market thanks to its commitment to customization, quality, and innovation. Its highly customizable solutions are meant to meet the specific needs of any client, so that the product can become a seamless part of any other business’s manufacturing process. These products are also built to be durable and to reduce both waste and energy consumption, with a mind toward the reduction of clients’ environmental footprint (hence the company’s emphasis on ‘lean’).

In reducing or even outright eliminating workplace clutter and disorganization while improving time, visibility, and employee wellbeing in the workplace, the company draws closer to achieving its goals of more efficient and effective workplaces for its customer base. Being so committed to each client’s needs means that great care is taken to make sure everyone is listened to. Every client interaction is made with open and transparent communication as a key value, including keeping a dedicated customer support team on hand for any kind of assistance necessary.

“We deliver solutions that truly add value to the client’s operations,” Meyer says, and the addition of custom solutions requires a degree of transparency that LEAN is ever ready to offer clients from every corner of the manufacturing sector.

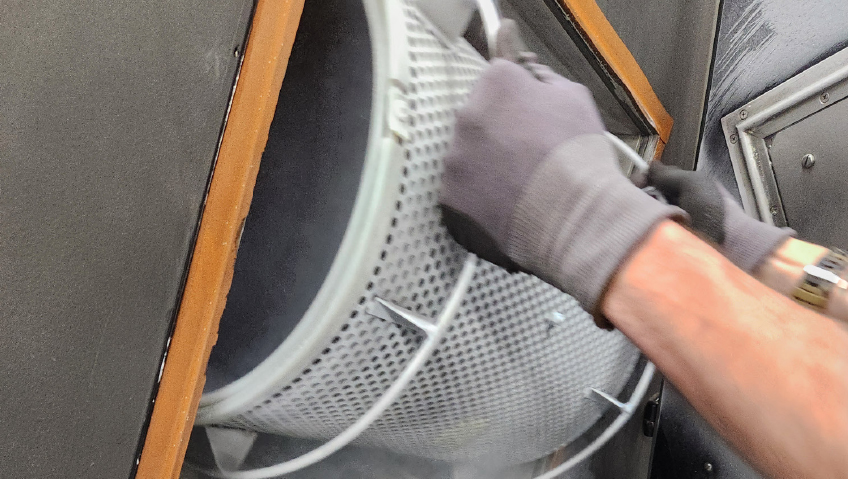

In recent years, LEAN has achieved its goals around innovation and customization through a variety of methods: first, through the development and adoption of its returnable re-rack cartridge design, the need for wooden pallets in a storage facility can be basically eliminated, thereby reducing waste and streamlining the shipping and receiving process. Re-rack cartridges are also engineered to protect materials in transit, minimizing damage and increasing reliability. Through this approach, LEAN has managed to bring steel suppliers onboard into using its returnable cartridge system, bringing the cartridges closer to becoming an industry norm and further promoting sustainability in manufacturing.

The re-rack cartridge system is also a representation of the LEAN commitment to sustainability and the environment; through its use, space utilization in storage and transportation can be improved, meaning more materials can be shipped in a single load, thereby reducing transportation costs as well as emissions.

Just this past year, LEAN furthered its new product development by working on coil storage racks for different size formats and weight capacity, including long-stock racks for storing tubing, extrusions, flat irons, and rods.

The manufacturing sector in the United States is one that is often at the mercy of both large-scale trends as well as customer demand, and Meyer says that no matter what lies ahead, LEAN is poised to play an important role in the evolving landscape of manufacturing and storage solutions therein. “Our commitment to innovation and sustainability aligns perfectly with these industry trends,” he says, and the company’s economical, sustainable, and high-quality solutions will allow all its customers to remain competitive in a rapidly changing market.

Indeed, the LEAN team foresees a future where lean manufacturing solutions like the ones it offers are integrated into every manufacturing plant across the country, so its goal is to be at the forefront of such a movement by continually driving the adoption of these efficient and effective principles.

While many businesses across diverse fields are experiencing a downturn in the workforce due to an aging employee population, Erschen says that LEAN is continually getting smarter about integrating a next-generation talent pool into its workforce. A big part of what is attracting young people to the industry, he says, is the ability of companies like LEAN to bring storage facilities to a state-of-the-art quality, effectively modernizing them. This goes along with an industry-wide shift away from the classically dark and grimy image of work in metal contract manufacturing into a brighter and cleaner future. Erschen says that the company is constantly buoyed by a great team that continues to adapt and grow along with the industry itself.

As the first half of the ’20s is nearly complete and the company inches closer to its first decade in business, LEAN will remain the distinct leader in its sector through continued investment in research and development. The company also plans to continue fostering partnerships with key stakeholders. Looking to expand its industry impact while continuing to drive innovation in the manufacturing sector, LEAN’s goal is to become the go-to provider for exactly what its namesake describes: lean manufacturing products. In doing so, it can continue to help businesses across America achieve their operational goals and drive sustainable growth.

Greater efficiency is a growing concern in today’s manufacturing landscape, and Lean Manufacturing Products aims to be the face of this growing movement for a long time to come.