Many companies offer custom molding, but Currier stands out with a portfolio of highly detailed and comprehensive services. Longstanding clients consider the company a powerful extension of their own operations due to its deep commitment to quality and customer satisfaction.

Specializing in more than just plastic pellet processing, the Currier team excels at maximizing profitability for customers by focusing on the minute details of their processes.

Currier identifies and addresses areas for improvement by thoroughly examining customer processes, often working directly on site. “We focus on being a broader supplier-partner to companies,” says Ron Ringleben, Vice President of Business Development. “Everything we do is 100 percent customized to specifications. We don’t make the same part for two different customers.”

Operating from two facilities in Auburn, New York, Currier handles complex processes for clients, some of whom have been with the company for over a decade. As these projects are scaled up, Currier adds volume and value, reducing carbon footprints and improving sustainability. In one instance, the company saved a customer nearly 80,000 miles in packaging transportation mileage over the course of a year—a benchmark it aims to surpass in future years.

Troubleshooting clients’ fabrication, packaging, and shipping processes has been a key part of the company’s expertise since its early days. When its leadership realized that standing out in unique ways would guarantee the company’s longevity, they tasked engineers with developing innovative solutions that would improve both productivity and customers’ bottom lines.

The result is a fully integrated, full-service offering that sets Currier apart, providing everything clients need in relation to the plastic components it supplies. Beyond molding services, Currier also offers parts assembly, parts and systems engineering, parts fabrication, packaging development, logistics, warehousing, and more.

The company also diversified to offer both blow molding and injection molding services, particularly to the medical industry, specializing in consumables for in vitro diagnostics and life sciences.

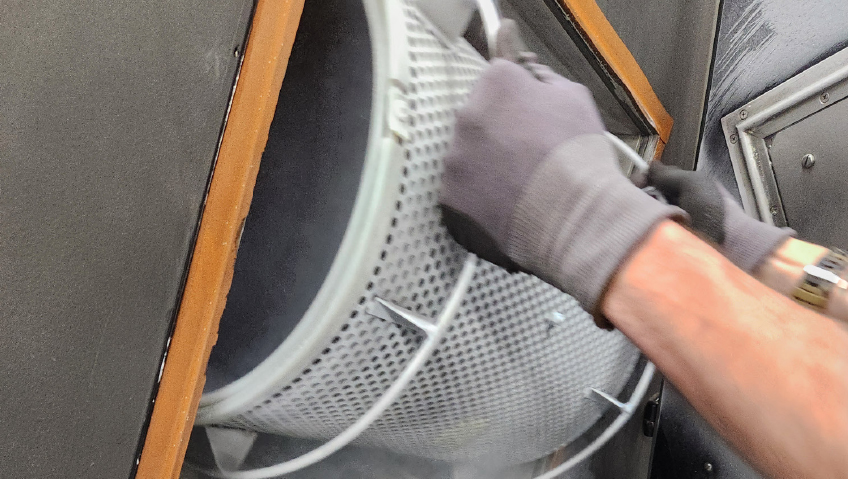

As an ISO 13485-certified outfit, Currier is capable of meeting exacting tolerances through sophisticated automation. This specialization has made the company a niche supplier with highly sought-after capabilities for leaders in the medical field. Other key parts of this offering are the inspection and verification of parts, assembly, packaging, and shipping.

John Currier, now President, joined the company founded by his mechanical engineer father, Raymond Currier, in 1982 when he was nearly 60. John’s leadership has fostered a supportive company culture that has earned deep loyalty from its staff. “My father’s influence outlasted his time here,” John says of the period following Raymond’s retirement in 1987. “I was in college at the time and thought, ‘How do we know we can do this?’ My brother Jim, on the other hand, took the view of ‘How do you know we can’t?’” John recalls, reflecting on their differing perspectives on their father’s decision to start the company at such a late stage in life.

With a strong technical background, Raymond Currier brought unique insight to his sales role, which he described as that of a “sales engineer.” Today, the company has an engineering sales team that fulfills this same function. “We provide a solution to you. And it might not be what you’re thinking,” John says. All customers are welcomed with the same all-hands-on-deck approach and attention to detail, with a focus on solving pain points quickly and efficiently. The process is thorough, leaving no stone unturned in finding the best solution tailored to each customer’s unique needs.

To uphold its strong and supportive company culture, Currier hires for more than just technical skill. The company uses a meticulous hiring process to ensure that every new employee is an ideal fit for its culture and committed to the company’s long-term goals. For potential hires joining the team from much larger companies, for instance, Currier’s high level of involvement and technology-driven approach must be a comfortable fit for them to join the team.

At Currier, big achievements are celebrated with initiatives like ice cream trucks, cookouts, and other fun team-building activities that bring people together to unwind. This positive attitude, combined with a carefully considered hiring process, has helped Currier earn a spot on Plastics News’ list of Best Places to Work three times in recent years.

“We leverage the benefits of being a smaller company. Bigger companies tend to lose that culture, that small feel,” John says. Protecting and nurturing this culture has helped the company weather staff shortages.

Currier’s commitment to hiring passionate people has also helped the company build long-lasting relationships with customers who know they can rely on the team during challenging times.

John’s philosophy on investing in enthusiastic problem-solvers is simple. “Being energetic, passionate, and optimistic—it fuels the people around you,” he says. In return, employees are encouraged to embrace lateral thinking and explore new possibilities that could benefit customers.

Currier is committed to evolving alongside emerging technologies, ensuring that its clients get exceptional value beyond the company’s molding services. By integrating next-generation systems into everything from assembly to packaging, the company has become a preferred solutions provider for many customers.

“A lot of this focus is on our healthcare clients,” says Ron Ringleben, Vice President of Business Development. “We’re taking parts and assembling multiple pieces. We’re either buying customer-specified parts or making multiple parts and assembling them.”

In the past, labor issues largely drove automation in the medical industry; today, however, the main driver is precision—something that’s simply unachievable without automation. “A lot of automation now has a dozen cameras to inspect parts. Not only do these cameras inspect parts, but they also log inspections,” John explains, emphasizing the importance of traceability in the field. As a result, while the company’s early investments were focused on primary machinery, recent years have seen more capital invested into customized automation than any other equipment. Today, Currier’s engineering team specializes in seamlessly integrating automation into its molding processes.

Thanks to its speed and efficiency, Currier is expanding its market share in the healthcare industry, accelerating its already strong growth trajectory. This trend is expected to continue for the foreseeable future. And, alongside this focus on healthcare, Currier continues to serve a variety of other markets, including packaging. With its sights set on continued growth and expansion, Currier is optimistic about establishing a presence in Europe.

“With the right customer base, we can do it,” says John.