Supermaterial applications company Lyten has signed a memorandum of understanding with Dermody Properties to locate its new lithium-sulfur battery gigafactory, a world’s first, on land near Reno, Nevada owned by the Reno-Tahoe Airport Authority. The facility, when at full capacity, will produce up to 10 gigawatt hours of lithium-sulfur batteries annually.

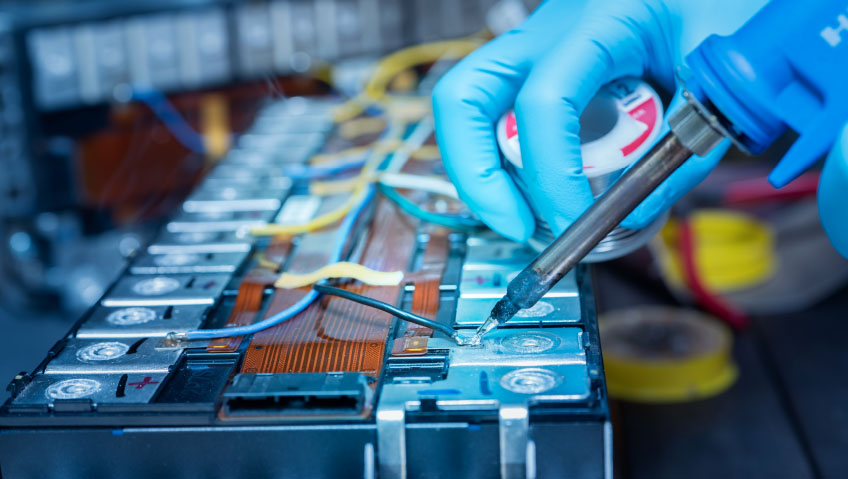

The facility will manufacture cathode active materials and lithium metal anodes and assemble lithium-sulfur cells in both cylindrical and pouch formats, which will support the production of a fully domestically manufactured battery.

The company will invest more than one billion dollars and the facility will create 200 initial jobs, an economic impact that is likely to grow to more than 1,000 jobs over time, which will be a beacon for the northern Nevada economy.

“Nevada is emerging as a key hub for U.S. battery manufacturing, and Lyten’s choice to build the world’s first lithium-sulfur battery gigafactory here underscores the strategic advantages our state offers to leading tech companies,” said Nevada Governor Joe Lombardo. “With our robust infrastructure and skilled workforce, Nevada is well-positioned for continued growth and job creation well into the future.”

Lyten is working with local universities, including the University of Nevada-Reno (UNR), Truckee Meadows Community College, and the Nevada Native American and Tribal members to secure talent and training to scale its operations.

Phase one of the planned 1.25-million-square-foot facility, located on a 125-acre campus in the Reno AirLogistics Park, is expected to be online by 2027. Lyten has been manufacturing CAM and lithium metal anodes and assembling batteries at its semi-automated pilot facility in San Jose, California, since May 2023.

“Today is the latest milestone in Lyten’s nine-year history. Lithium-sulfur is a leap in battery technology, delivering a high energy density, lightweight battery built with abundantly available local materials and 100 percent U.S. manufacturing,” stated Dan Cook, Lyten Co-Founder and CEO.

The company’s lithium-sulfur cells offer high energy density that will enable up to 40 percent lighter weight than lithium-ion and 60 percent lighter than lithium iron phosphate (LFP) batteries. The cells utilize local materials that are available in abundance thus eliminating the need for mined minerals like nickel, cobalt, manganese, and graphite, making them lower cost than the alternatives as well.

With an existing pipeline of potential customers, Lyten’s lithium-sulfur batteries are expected to hit the micromobility, space, drone, and defense markets in 2024 and 2025. As it stands, Lyten is working with Dermody Properties and the Reno-Tahoe Airport Authority to finalize contractual terms to support breaking ground in early 2025.