It is quite extraordinary how much can change in only five years. Black Controls Company Inc. has shifted from a fledgling enterprise to a full-scale fabricator active in 15 countries. Its market presence in the general industry, automotive, and sterilization sectors grew significantly over the past 12 months, resulting in sizeable shifts that it is navigating successfully thanks to its prevailing culture of trust, support, and continuous improvement.

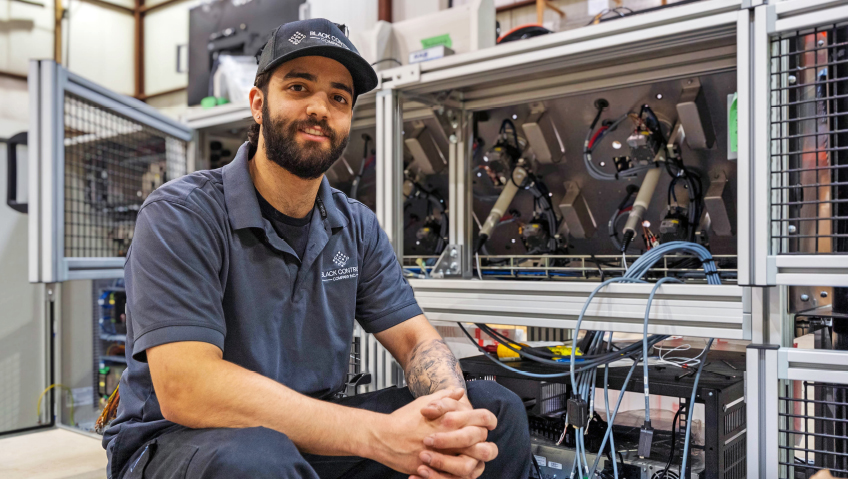

Proud of its entrepreneurial drive, the company has now superseded its goals from a year ago and continues pushing forward with impressive and stable speed from its modern, 13,000-square-foot facility in Barrie, Ontario. Black Controls Company offers custom, turnkey industrial and robotic control systems, with design, engineering, fabrication, mechanical, and programming services.

The company is also well-equipped with operations, engineering, manufacturing, assembly, and development departments—all engineered for optimal output. Growing from around 20 permanent staff members to 25 in a year is a sign of more growth to come.

The company hit the market at precisely the right moment when it opened for business in July 2019. Today, its capabilities include complete systems and software engineering, industrial robot systems, and advanced human-machine interface devices. These enable reciprocal communication between humans and machines. The team also develops and builds programmable logic controllers, executes upgrades to and retrofits of existing systems, performs quality checks, and more.

It has been an industrious year for the company. Building its market presence with a growing sales team and service network, it has also identified the need to expand its engineering and mechanical design departments. Moreover, the company recently received its International Standards Organization (ISO) 9001:2015 certification and is also in the planning stages of implementing a resource planning system, enabling the team to make their systems, workflow, and processes even more efficient. The company also remains a proud member of the Canadian Tooling & Machining Association (CTMA).

Alongside all its training activities, the company also continues to be supported by the Career-Ready with CTMA: Expanding Opportunities program, which runs for four or eight months, with several assessments throughout. “It’s exciting to track each individual’s growth throughout the program,” says Mike Lake, Electrical Team Leader. Black Controls is also a member of the WSIB Excellence Program, a group of over 2,000 employers representing businesses of all sizes and industries who are dedicated to workplace health and safety.

With a regular supply of new students from its local cooperative college, Georgian College, the company has a solid workforce as students coming to it from the Electrical Technology Program or the 309A electrical apprenticeship program. Recently, a member of the Black Controls team attended a Horner Canada Programming Course, while two others completed the G2/G3 Series Robot Basic Operations Training Course. Two members of its programming team also passed their mobile industrial robot (MiR) 2024 expert training not long ago.

Maintaining excellence is crucial, considering the stakes, and so is safety, so Rick Black, owner and winner of Manufacturing AUTOMATION’s ‘Top 10 Under 40’ in 2021, ensures that everyone is prepared for the job. Packed with practical, useful information, recent training includes a course by supplier Hills and a seven-day TÜV Reinland Certified Machinery Safety Expert training attended by five design team members. The team benefits handsomely from this training. “We appreciated the opportunity and Rick’s eagerness to let us go and learn. It was very technical and very beneficial to everyone who attended,” says Jon Ferrier, Design Team Leader.

The company also ensures that its leadership team gets all the support it needs to make the right decisions. Leadership, culture, and strategy training is regularly attended by five of its members and for this, the company contracts a professional leadership coach from Cohesive Strategy Group. With a thorough understanding of the organization’s inner mechanics, the analyst/coach assists in protecting, developing, and maintaining company culture. “This mentorship is a good fit for us because everyone has a busy schedule,” says Lake.

In addition to its full-time staff, the company’s co-op student employees from Georgian College pass through its departments throughout the year. In May this year, two new students joined, adding to the outfit’s mechanical and administrative capacities. “We are growing but we’re also stabilizing. Our young staff made huge strides in the past couple of years,” says Ferrier. He points out that training younger staff is a priority during this time.

Having younger employees to follow in the footsteps of seasoned staff members gives the company the tiered knowledge and experience it needs to maintain stability long-term. Ferrier notes that the entire team values professional growth as everyone commits to the continuous development of expertise. “Everyone takes pride in their work and in keeping quality paramount,” he adds.

Black Controls Company continues to develop itself as an industry leader in autonomous robotics. The team recently created an entire robot cell—from design and fabrication to wiring and programming—all in-house before disassembling and reassembling at the customer’s facility. The project was a tremendous success, and now others await completion.

New and existing business is on the rise at the company, and this summer will be marked by much global travel, mainly to conclude sophisticated conveyor systems projects for one of its biggest clients. “While we are focusing on our growth and diversifying our customer base, this partnership remains strong,” says Ferrier. The team is also building industrial-sized material handling robots for a project—a specialized task that will further hone its capabilities.

As well as building its new customer base, the company has also welcomed short-staffed manufacturing customers from its immediate surroundings and the Greater Toronto Area that are in need of expert wiring and controls assistance. Black Controls visits client facilities to provide support to increase output during high-demand periods until re-staffing is possible.

This indispensable service has seen its people integrating seamlessly with customer operations, helping when needed and turning such situations into beneficial situations for customers. “For us, it’s not just a job; it’s a true partnership,” Ferrier says, noting that the company helps clients “hit their goals, and build good relationships that hopefully last for years.”

While the company certainly prizes its customer relationships, it also cultivates a positive spirit amongst its own staff. “I like the energy of the team. Most people are still at the beginning of their careers, so they have a bright future ahead of them,” Ferrier says of watching colleagues reach their highest levels of professional capability. Watching co-op students completing trade school and becoming quality contributors to the Black Controls team is a genuine pleasure for him.

This team does know how to have fun, however. The company makes its mark on the tradeshow front, attending its first one just last year. Collaborating with the Cities of Barrie and Orillia, the County of Simcoe, Georgian College, and Lakehead University, the Canadian Manufacturing Technology Show (CMTS) provided great excitement as just about every employee got to represent the company at its booth. The opportunity to gain even more exposure for its latest projects was a welcome boost.

Hannover Messe, the world’s second-largest tradeshow of its kind, was also attended by the company “as a vendor in the Canadian Pavilion hosted by Next Generation Manufacturing Canada (NGen) from April 22 to 26 this year. The fair typically sees 130,000 visitors welcomed by around 4000 exhibitors, a significant and exciting achievement that brought us tremendous exposure,” says Cheney. “But this show took us further toward becoming a true global integrator.”

The company’s charitable contributions are now also stronger than ever. Showing its support for the Barrie Baycats baseball team’s camping activities, the entire company also participates annually with Christmas Cheer, pooling ideas, time, and money to support families in need. Then there is its sponsorship of a fun activity book for hospitalized children, which has become another proud tradition.

As increasing sophistication, speed, and automation drive market evolution, Black Controls Company is ready for action, and considering its expertise in medical and food sterilization processes, it is also poised for notable expansion.

“As a company, we want to continue to build and foster the culture of trust, support, and continuous improvement that we have now,” Cheney says. “We love what we do. We challenge ourselves to [work] outside of the norm.”

With a dedicated team that hears customers’ needs and answers them in ways that deliver above and beyond expectations, it is exciting to watch this young giant step into the future.