Robotics is an ever-growing field across a bevy of disciplines, including within manufacturing and its partner industries. More and more companies are beginning to see the benefits of adopting automated solutions to factory processes, fabrication, and more. Beyond the facility floors of various production lines, great strides are being made towards robotics that can fit on the tip of a finger, which is where the fields of micro and nanorobotics come in to evolve the future of automation potentially further in manufacturing.

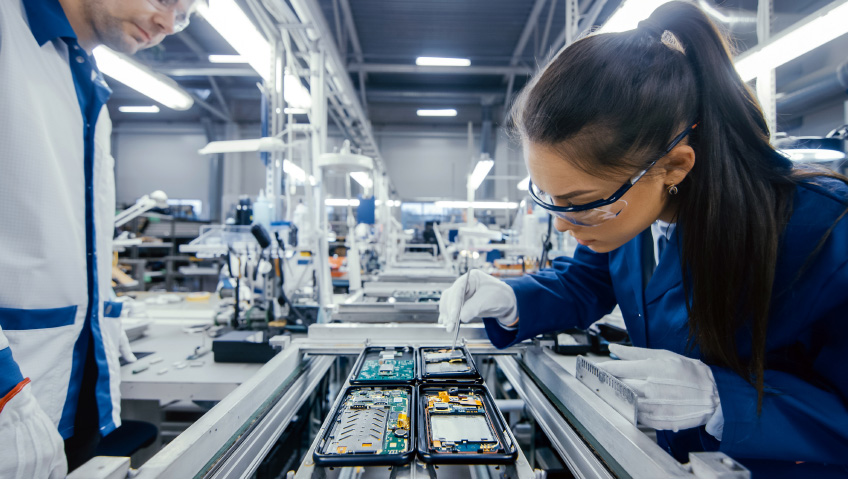

Microrobotics is a field concerning the development of automated machines as small as a millimeter for use in various spaces. The idea of microscopic robots has been bandied around since the 1950s, and modern technology continues to draw closer to achieving the initial dream of what they could possibly do. A blog entry for Leotronics titled “Small miracles: micro robots and their applications” says that the history of microrobots is traced back to the development of the microcontroller at the end of the 20th century, an integrated circuit which itself gave way to miniature mechanical systems. Today, microrobots are usually manufactured through microfabrication processes like 3D printing.

Jacob Biba, in a piece titled “Microrobotics: Tiny Robots and Their Many Uses,” says that microrobots are seeing primary usage today in the biotech industry to continue development of diagnostic and therapeutic tools to monitor and treat disease. Microrobots are also seeing use within environmental studies, search and rescue operations, agricultural research, and more. These robots are small enough that researchers in the field are developing applications to insert them into human bodies and to target and eliminate microscopic diseases and conditions like cancer or blood clots. Biba says that one researcher from the University of Massachusetts Lowell is even working on a robotic bee that will be able to shake pollen from flowering plants.

The potential for microrobots goes beyond human-centric operations, too. In an article for IEEE Spectrum titled, “SRI’s Micro Robots Can Now Manufacture Their Own Tools,” Evan Hackerman says that research and development company SRI International has introduced its MicroFactory platform, which uses hundreds of tiny robots to build large-sized structures by cooperating. This has necessitated the further development of a tool shop for the MicroFactory that can make custom-fitted tools so that each robot can perform its specific task. The MicroFactory works at a small scale to help create strong walls and roofs, and further development could see them being placed into larger robots to perform on-the-spot maintenance. Although there are several ways to manufacture microrobots, it could be that, eventually, even their development and construction may be out of human hands.

Nanobots are much like microrobots but another order of magnitude smaller, dealing with the manipulation of atoms and molecules and the creation of systems and devices on that scale. For context, while microrobots are generally as small as a millimeter, nanobots are only around 50-100 nanometres wide. Keep in mind that there are one million nanometres in one millimeter.

This even smaller size makes nanobots ideal for jobs like drug delivery. In “The miraculous anatomy of the digital immunity ecosystem,” Dr. Rocky Termanini says that while drugs work through the entirety of a human body, “Using nanotechnology, the drug can be targeted to a precise location which would make the drug more effective and reduce the chances of possible side effects.”Umar Sajjad, in “How Are Nanobots Powered?” says that “nanotechnology is among the fastest-growing technical disciplines, with a market value of $1 trillion and a projected growth rate of almost 20 percent within the next decade,” with nanobots a part of that thriving ecosystem.

The biomedical and biotech applications of nanobots are like microrobots but differ in crucial ways. In “Arming Biological Nanobots to Deliver Drugs Inside Our Bodies,” Carlos de Rojas says that nanobots could be a solution to the toxicity of medical treatments like chemotherapy. The nanobot has the capacity to deliver a medical payload to the directly affected area of the human body, minimizing any damage to unaffected areas. This is possible by combining the inorganic elements of nanobots with biological parts (i.e. human cells, DNA), allowing the robots to be inserted into human bodies, work quickly to the target area, and then self-degrade safely within. This is also possible with microrobots, with the added benefit of greater maneuverability but at a greater size, so the smaller frame of a nanobot is usually preferable for this specific task.

De Rojas says that the Harbin Institute of Technology in China has gone as far as to create “neutrobots” that can stop the growth of tumors in the brains of mice by hiding inside immune cells in the body while loaded with a cancer drug. “In the future, nanobots may integrate a variety of hybrid structures, cell, and tissue types, building blocks of DNA strands and proteins, and a range of mechanisms that could give them sensitivity to different pathogens. They also could include vascular networks for transporting nutrients, and neural networks for sensing and processing information,” says de Rojas.

These paths forward are full of promise but are not quite where they need to be yet. In his article, de Rojas says that nanobot development into biotech areas is promising, but is still in the early stages, and nanoscale manufacturing is still seeing problems at various parts. “Scientists in the field still have many challenges to tackle, such as the limited lifespan of biobots, the lack of intelligent perception, and a lack of imaging techniques that can track nanobots in real time.”

The body’s immune system response is another challenge for nanobots in the biotech sector, as it can be rather aggressive in eliminating any perceived threat. Umar Sajjad says that nanobots are always in need of energy, whether internal or external. Internal energy can be supplied by onboard generators that convert electrolytes in the bloodstream into usable power. External energy involves fiber optic wires connecting the robots to power outside of the nanobot. These external sources could be magnetic fields or ultrasonic sounds, converted into electrical power.

In “How Are Nanobots Made? Understanding Nanotech Problems and Solutions,” Lou Farrell says that nanobots require three basic components to function: a transportation mechanism, an internal processer, and a fuel unit for propulsion. It is still a challenging prospect to create a machine as small as a nanobot that can be self-propelled and capable of highly specialized tasks while also remaining durable. While atomic power seems to be a promising solution to the creation of a fuel unit, as it would not need replenishment and would create sufficient energy, silicon is the preferred material to create the robots. Biological components are also an interesting possibility, as combining molecules like DNA with them could mean the production of nanobots that can assemble and replicate themselves. Some of this is still theoretical or in development, but there is a great deal of enthusiasm in the space for it.

What once seemed like the plot of a science fiction story, the shrinking of machines to enter small spaces a la the classic sci-fi film Fantastic Voyage is slowly becoming a reality thanks to advancements in robotics unlike what has been seen before. Manufacturing science will continue to find ways to make the seemingly impossible come to (artificial) life, to the benefit of not just the sector, but hopefully, humanity at large.