Things are booming at Samuel Automation Solutions Group (Samuel ASG) of Waterloo, Ontario. “We’ve gotten stronger. We have a greater reach and expertise. Being part of a much larger organization demonstrates stability that the smaller independents don’t always have,” states President Robert Lague.

Until recently, he worked exclusively for Systematix, a company that custom-designed and built automation systems for manufacturers. In 2021, it was acquired by Samuel, Son & Co. a ‘leading metals and industrial products manufacturer, processor and distributor,’ in its own words. Founded in 1855 and based in Oakville, Ontario, it boasts a global presence. Samuel joined Systematix with CAID Automation and RAMP, two other automation and technology companies it owned, and the group was born.

Custom design work remains the norm at the new company. “Our customer always brings the process they want done and, typically, provides some form of user requirement specification. We call it a URS. Some customers leave it up to us to specify the hardware,” says Lague.

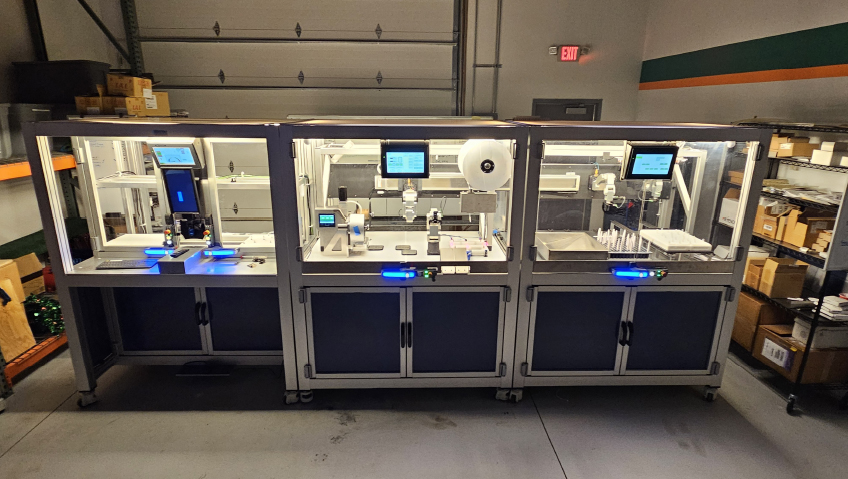

Samuel ASG’s automation systems are used for testing, inspecting, components assembly, packaging, and robotic handling. Solutions often contain camera systems or vision sensors as well as data collection tools. Automation solutions developed by the company are intended to increase productivity, streamline operations, and identify flawed parts. Some solutions also feature remote monitoring capability, so clients can scrutinize the performance of their systems.

Most of its work is self-performed although the company does buy equipment from outside companies, including robotics from FANUC, ABB, and other original equipment manufacturers.

Its main markets range from automotive and transportation to life sciences and consumer products. Within these categories are specific sub-markets; life sciences, for example, includes medical devices and pharmaceutical wares, while consumer products include window and door automation solutions.

As far as Lague is concerned, the creation of Samuel ASG has been a boon for everyone involved.

“Prior to being acquired by Samuel, Systematix had been in business for just over thirty years providing complex assembly solutions to a wide variety of customers. We had a very high percentage of repeat customers, and our customer base was relatively stable. Samuel gave us visibility to a larger customer base, and at the same time, the Samuel brand has created some additional exposure in the marketplace we didn’t have before,” he asserts.

Mutual assistance is one of the benefits of being under the Samuel, Son, and Co. umbrella. “We’ve begun working with the different Samuel companies, helping them find automation opportunities to improve their quality, production throughput, that sort of thing. So, we’ve done a number of smaller projects, and we’ve got one bigger line for a plant about an hour away from us here,” says Lague.

“We’ve capitalized on the companies’ ability to work with each other. For example, CAID Automation has engaged in design efforts for Systematix on a project where we needed extra resources. CAID has also helped on an installation in the U.S. for RAMP. They had people who were local they could send in and help with that install at the customer’s site.”

Sales teams for the three companies “now have a larger range of capabilities that they can sell to customers,” he adds.

Customers have also benefitted. Whereas in the past, a client might have had to work with several automation firms to complete a project, the entire assignment can now be handled by Samuel ASG depending on the skill sets involved.

While the individual companies within the group have become stronger, the company remains nimble and quick on its feet. “Across our business units, we have financial stability, processes, and expertise that is similar to the largest automation companies in the world, but we’re more agile and can provide lower cost solutions because we don’t have the overhead some of these really big companies have. We operate three independent companies that communicate well,” Lague states.

Samuel ASG has roughly two hundred employees. Experience is preferred in new hires, but it appreciates other traits as well. “Seasoned automation professionals are one of the things we’re always on the lookout for. We want self-starting, team-oriented individuals—people who like to problem solve and work with technology. Someone who likes to learn would fit very well into our organization because we’re constantly doing new stuff. We hire from both streams as far as college or university are concerned. We also have apprenticeship programs in different areas of our business. We can intake team members at all sorts of different areas,” he says.

In fitting with this innovative culture, it has a strong online presence, with profiles on social media platforms, but this is augmented by old-school promotion. The company regularly attends trade shows such as the upcoming Automate conference in Detroit this May.

In addition to innovation, Systematix and its sister companies have a reputation for doing quality work.

Systematix is ISO-certified and Samuel ASG has developed business best practices for “all areas: project management, shop floor, and design. These have been established and rolled out to each of the business units. As we grow and we add a new company, we compare our current standards with what the new company brings, and then we’ll try to make everything better. This has all been done in collaboration with the three businesses, and as we grow, we’re going to see if we can continue to improve our processes,” Lague explains.

When it comes to noteworthy projects, he mentions a jumbo-sized assignment involving an assembly line for truck transmissions. “The finished product was over seven thousand pounds when completed,” he notes, adding that the solution was shipped before the Christmas holidays.

As with every industry in North America, Samuel ASG had to cope with COVID. When the virus spread in early 2020, the company went into action. Desks were separated, and an employee temperature check-in system was established. The company tried to encourage remote work but discovered this model was not a good fit.

“Because a lot of our work is based on innovation, we like people being closer together so they can talk when they have ideas… We’re a workforce of problem-solvers. Our people are curious about team things. They thrive in the team environment that we need to complete our systems,” says Lague.

The company’s bottom line was not battered by COVID as some of the clients with which it works supply masks and testing devices so it was “actually very busy during COVID,” he recalls. Still, it has experienced virus-related supply chain woes.

“The stuff you’re hearing about all over is happening to us too. The chip shortage has caused us a lot of problems. The backlogs, because of the shutdowns in China that are affecting everybody’s supply chains and the components that we buy, that’s really affected our deliveries,” he says.

The company has been known to improvise in the face of supply chain delays. If commercial semiconductor chips are not available, a lift-locate unit might be fabricated in-house as a temporary stand-in for testing during the construction of a conveyor system.

Not counting COVID, Lague says hiring is the biggest challenge. “Finding talented people with a thirst for knowledge and experience in our field, it’s tough to do. We’re always looking. We’ve got postings on LinkedIn and Indeed. We attend college and university recruiting fairs. We host job fairs where we open up our facilities and invite candidates to come in and see what we do.”

In the future, growth, new services, and a continued emphasis on innovation are all on the agenda. The company has hired a new service manager to create “some new after-sales service offerings,” and is participating in pilot projects involving artificial intelligence (AI), says Lague. These projects were started by the parent company before the birth of the ASG.

“Now that we’re working with them, we’re going to do two or three test projects this year to actually put [AI] on equipment we build for Samuel and then be able to run it in-house so we can learn what it does, what its capabilities are, what the worth is to our customers, and ultimately, get out of that something we can offer to the marketplace,” he explains.

While each location within Samuel ASG is growing organically, the company is also keeping an eye out for “strategic acquisitions that can give us more of a technical capability and greater regional support throughout North America,” he continues.

Moving forward, “We are actively planning the Samuel ASG to have more business units in it and for these to be in regions mostly in the U.S. [That’s] where we’re looking to grow and to gain more technical know-how in the process,” Lague adds.