Contact with moving machine parts, slips and falls, chemical burns, falling objects, fatigue, overexertion, and vehicles are just a few causes of workplace injuries. Fortunately, technology and smart factories can make manufacturing far safer…

The macabre fascinates us, and no television show embodied our dark curiosity about accidents, illness, and reckless, life-ending antics more than the aptly-titled 1000 Ways to Die. Even today, over a decade after the docufiction anthology series ended its six-season run, viewers vividly remember the show’s mishaps and mayhem.

Unsurprisingly, many episodes centered on people acting foolishly and paying the ultimate price in gruesome ways many of us could never imagine. Recreating fatal incidents with actors, animations, stunt people, and special effects, episodes documented the misadventures of well-known historic figures like fabled escape artist / illusionist Harry Houdini and American distiller Jack Daniels, or sometimes retold tales of workers ignoring safety, falling into a vat of acid, or being impaired on drugs and maimed while playing around with a forklift.

Tragically, these cautionary tales weren’t far removed from actual incidents going on worldwide today, with workers losing a digit, a limb, or their lives through carelessness (theirs or someone else’s), improperly maintained equipment, a lack of personal protective equipment (PPE), inadequate training, or failing to respect health and safety protocols.

According to the International Labour Organization (ILO), approximately 2.3 million men and women “succumb to work-related accidents every year; this corresponds to over 6,000 deaths every single day.”

A global issue

Many of these deaths are in developing countries, where causes include work-related diseases and death by hazardous substances, estimated to claim about 650,000 lives annually. But Western countries, too, need to be mindful of their own workplace accidents.

According to the 2022 Report on Work Fatality and Injury Rates in Canada from the University of Regina, work-related causes claimed the lives of 924 workers in 2020. And the U.S. Department of Labor’s Bureau of Labor Statistics notes that there were 5,190 fatal work injuries in the United States in 2021, an increase of 8.9 percent from 4,764 in 2020: “The fatal work injury rate was 3.6 fatalities per 100,000 full-time equivalent (FTE) workers, up from 3.4 per 100,000 FTE in 2020 and up from the 2019 pre-pandemic rate of 3.5.”

Some of the deadly causes included slips, falls, trips—which also increased 5.6 percent from 2020 to 2021—exposure to harmful substances or environments, and transportation-related incidents.

101 minutes

Along with additional, preventable deaths, other key findings reveal disturbing trends. The 3.6 fatal occupational injury rate of 2021 represented the highest annual rate since 2016. In 2021, a worker in the U.S. died every 101 minutes from a work-related injury. That same year, the number of Black or African American workers fatally injured on the job jumped from 11.4 percent of total fatalities (in 2020) to 12.6 percent in 2021, an all-time high.

Although the construction sector is responsible for most of these accidents and deaths, manufacturing is not far behind, with many incidents the result of improper use of PPE, carelessness, ignoring safety standards, and acting before thinking about the consequences.

Manufacturers frequently share the blame with their workers. Earlier this year, a Pennsylvania candy company was fined almost US $15,000 after two unauthorized, improperly trained workers fell into a partly filled chocolate tank and had to be freed through a hole cut into the tank’s bottom. Fortunately, both the above workers survived, unlike a mother of two in Russia in 2016, whose similar accident resulting in death made the world reel.

It is believed candy factory worker Svetlana Roslina, 24, had accidentally dropped her cell phone into a massive mixing tank of molten chocolate, or perhaps was adding a sack of ingredients when she fell headfirst into the boiling tank. When rescue crews arrived, only her legs remained.

And just last year, a 39-year-old Illinois foundry worker was taking a sample of molten hot iron when he tripped and fell into a 2,600-degree Fahrenheit crucible, dying instantly due to “thermal annihilation.” It was the fifth day at his new job for this father of three.

Everyone’s business

As the saying goes, “Safety is everyone’s business,” and this is especially true in manufacturing. From being familiar with operating machinery to cleaning up spills immediately, there is much that can be done to ensure staff go home after their shifts with zero workplace incidents.

A safe and healthy work environment is vital not only to keeping production flowing, but to a company’s very existence; few people want to work for a manufacturer with a reputation for carelessness or for looking the other way regarding safety hazards and violations. Unsafe production floors take a toll on worker productivity, standards, and morale, and accidents can even impact the cost of products for consumers.

According to the latest industry data, 11,190,902 men and women are currently employed in America’s manufacturing industry. To protect these workers and others worldwide, safety guidelines must be in place and enforced. Manufacturing systems must also be designed to ensure they do not overload operation capabilities and do not limit workers through poor lighting or visibility, inadequate room to work, accessibility issues like obstructions or obstructed movement, and considerations like excessive noise, temperature, sound, and vibration.

The technology of safety

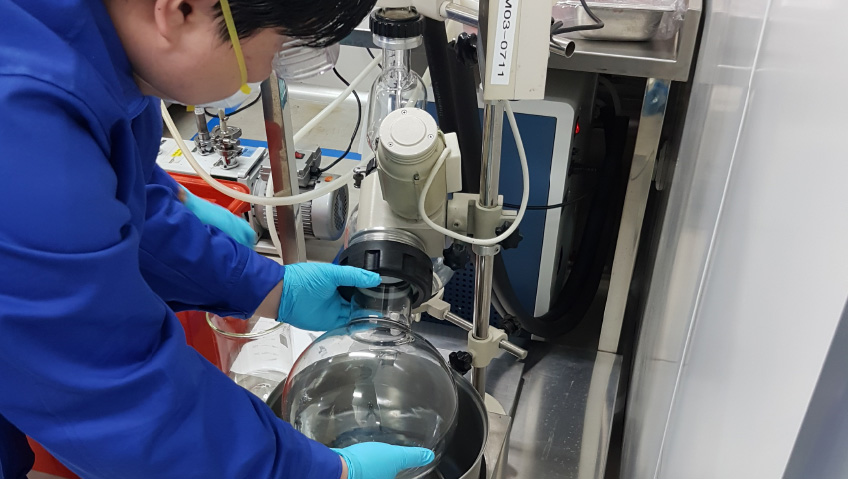

Along with conducting risk assessment, mandatory training and communication, keeping machinery in working order, and PPE like glasses, gloves, masks, and earplugs, technology is making manufacturing work safer.

Instead of old-fashioned spreadsheets, comprehensive software tracks not only performance and progress, but logs of incidents, employee safety training records, and more. Software can also track the maintenance of equipment and other assets, ensuring machinery not only works at peak efficiency but also functions safely.

One of the greatest causes of workplace injury in manufacturing is physical strain from lifting heavy objects and repetitive tasks. To reduce the risk of lower back injuries, some manufacturers are investing in robotic systems to literally take the load off human workers, significantly lowering the risk of musculoskeletal injuries or disorders. Most of these robotic systems, when operating in tandem with AI, learn and continually improve their performance. And for potentially dangerous manufacturing requiring extreme heat or cold, chemicals, noise, or gases harmful to human life, robots are ideal.

Another way technology is benefiting humans is through advanced medical monitoring, where breathing, hearing, and even particles of materials and chemicals that may have entered the system of a member of the workforce through inhalation, ingestion, or contact and absorption are measured before they become health issues.

Capable of much more than just filling in for a human worker, many robots have cameras and sensors and can detect potential hazards, preventing accidents before they can happen. This precise information is gathered, and the data analyzed.

Representing the next generation of manufacturing, smart factories and Industry 4.0 incorporate AI, robotics, interconnected machinery, communication tools, and machine learning. The need for better, safer, and more productive technologies became especially apparent during COVID when a combination of supply chain issues, manufacturing plant closures, and social distancing slowed production.

In May 2020, when death rates were climbing and stay-at-home orders were being issued, Forbes magazine published a strong piece underscoring the need for change. “COVID-19 has shown the world something that the manufacturing industry should already know,” said the article: “Traditional supply chains and manufacturing ecosystems are failing and we need to shift to a more adaptable, agile solution that is fully digitally enabled.

“The virus, like any crisis, has merely underlined both that need and the urgency and will likely serve to accelerate that change. This needs to result in real plans of action, rather than debate.”

Of course, for the benefits of AI, robotics, and other technologies to be successful, they must be founded on consistent, up-to-date training of both new and existing manufacturing employees and ideally, underpinned by a rich and comprehensive overarching culture of safety. Employers, employees, and automation all have roles to play in contributing to safer and healthier working environments for all.