On November 8, 2021, Walmart—the largest grocery retailer in America—made high-tech history in its hometown of Bentonville, Arkansas. Walmart announced it had successfully used fully autonomous vehicles (AVs) to transport goods along a two-mile route. This driverless pilot program, which saw Walmart partnering with AV firm, Gatik, began in August 2021.

AVs had been introduced a few years prior at mining sites, but such vehicles operate under controlled conditions in isolated locales. The Bentonville demonstration was unique because it involved public roads, commercial delivery vehicles, and no humans behind the wheel (i.e., “safety drivers” ready to take control should a malfunction occur).

While a previous Walmart / Gatik AV test did involve safety drivers, the 2021 demo represented “the first time that an autonomous trucking company has removed the safety driver from a commercial delivery route on the middle mile anywhere in the world,” shared a press release on Business Wire.

Proponents say AVs improve safety and productivity while lowering costs for companies. Before fully driverless commercial vehicles become commonplace, however, certain challenges need to be addressed, including regulatory requirements, technological limitations, and opposition from labour groups.

Founded in 2017, with headquarters in Mountain View, California and an office in Toronto, Ontario, Gatik maintains a fleet of trucks fitted with its proprietary autonomous driving technology. Gatik, which uses vehicles from manufacturer Isuzu, isn’t shy about highlighting its role in the fast-growing AV field.

“[Gatik], the leader in autonomous Middle Mile logistics, delivers goods safely and efficiently using its light and medium duty trucks,” states the Business Wire press release.

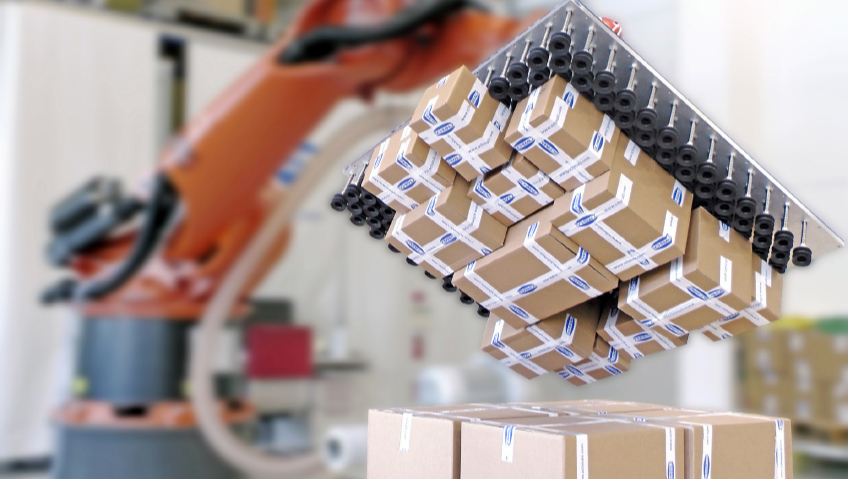

Middle Mile refers to B2B (business to business) deliveries between distribution centers, warehouses, retail stores, and other facilities, as opposed to bringing goods to a final destination (“last mile” delivery). In the Arkansas demonstration, groceries were moved between a ‘dark store’ (an outlet that stocks products but isn’t open to the public) and a Walmart Neighbourhood Market. Deliveries were made on autonomous, temperature-controlled box trucks several times a day, seven days a week.

To avoid collisions and stay on the road, autonomous vehicles rely on high-tech tools such as radar, Lidar (Light Detection and Ranging, sometimes spelled “LiDAR”), cameras, GPS systems, and sensors. Lidar allows a driverless vehicle to “see” in darkness and inclement weather. Radar is likewise helpful for navigating in rain, snow, or fog.

Walmart and Gatik also joined forces for a more extensive project, to move goods on a 20-mile route between New Orleans and Metairie, Louisiana using autonomous box trucks with safety drivers. Once again, the chosen route was fixed and consistent. Driverless vehicle technology isn’t sophisticated enough at present to handle home deliveries.

The year after the Bentonville breakthrough, Gatik made history again, this time in Canada.

On October 5, 2022, Gatik and Loblaw Companies Limited (the leading grocery and pharmacy retailer in Canada) announced they were collaborating on Canada’s first fully driverless delivery service. The announcement came after the successful completion of a pilot program in which AVs transported groceries in the Greater Toronto Area (GTA). Safety drivers were utilized for the pilot, which saw autonomous vehicles move food items from distribution centers to Loblaw’s outlets.

“More than 150,000 such trips were quietly done during the pandemic, and after completing all of them without a single safety incident, the two parties decided to take the next step: they sought and received permission from the province to go driverless, though they plan to have the safety driver sit in the passenger seat for now… If all goes well, the safety driver may one day be removed from the vehicle entirely,” stated an online CBC story posted October 5, 2022.

“Taking the driver out is the holy grail of this technology,” stated Gautam Narang, founder and CEO of Gatik, in a CNBC article.

As the CBC article pointed out, autonomous trucks require regulatory approval before they can hit the road, and Walmart and Gatik could only go forward with their no-safety-driver demo in Bentonville after receiving permission from the Arkansas State Highway Commission. Many companies are willing to deal with such red tape, however, given the benefits AVs offer. In the CNBC piece, Gatik claimed its driverless trucks can “reduce logistics costs by as much as 30 percent for a grocery business.”

Truck drivers require food, breaks, pay, and benefits, none of which applies when there isn’t a human in the vehicle. Regulations limit the amount of time a commercial truck driver can spend behind the wheel before taking a mandatory rest. Fully autonomous vehicles, by contrast, can operate around the clock, all week long.

AVs might also help companies struggling with a massive labour shortage. “Truck fleet operators are having a hard time hiring truck drivers. This year, experts estimate the shortage of U.S. truck drivers at 105,000. The American Trucking Associations trade group predicts the shortage will grow to 160,000 by 2030,” states a March 1, 2023 Investor’s Business Daily article.

What companies see as a benefit, however, labour groups view as a threat. The Teamsters union, which represents freight truck drivers, is not pleased by the prospect of fully autonomous vehicles. The California Teamsters branch has advocated for legislation that would require the presence of a safety driver in autonomous trucks.

Such advocacy goes beyond merely wanting to save jobs; critics of AVs point to a slew of recent incidents involving self-driving cars that burst into flames or malfunctioned at inopportune moments. Viral videos of such flameouts have attracted millions of views but are misleading; while some cars feature advanced driver assistance programs, fully autonomous cars don’t exist at present (at least not for the public). The reason has to do with technology. Cars need to deal with detours, potholes, pedestrians, and other elements in complex urban environments and are also used for long-distance travel. Creating automated driving technology for trucks doing short hauls on fixed, repetitive routes presents is far less daunting.

“Simply put, development of self-driving truck technology is leaving driverless cars in the dust,” wrote Investor’s Business Daily.

Indeed, delivery companies such as UPS, FedEx, and DHL, and other major grocery chains, are also teaming up with AV firms to try out driverless delivery vehicles.

For its part, the mining sector has been using autonomous trucks for years. Suncor Energy (“Canada’s leading integrated energy company” in its own words) made headlines in late January 2018 when the company announced it was introducing autonomous haulage systems (AHS) for some mining operations in the oil sands of Western Canada. The trucks in question were made by OEM Komatsu in what was the first implementation of a commercial AV haul fleet in the oil sands.

“Evaluations have shown that the technology offers many advantages over existing truck and shovel operations, including enhanced safety performance, better operating efficiency, and lower operating costs… Autonomous trucks operate predictably and employ a suite of safety features like prescribed route mapping and obstacle detection systems,” noted a Suncor press release.

Suncor isn’t the only mining company to adapt AVs either: “The popularity of autonomous haul trucks is gradually growing across surface mines, with miners taking advantage of improvements to productivity; reductions in accidents and operating costs; increased machine life and tire life and lower fuel consumption,” observed Mining Technology magazine on June 18, 2021. Autonomous mining vehicles are monitored and controlled by human operators from a control room.

Caterpillar, long a leader in the autonomous construction equipment sector, offers a program called Cat MineStar Command. The system builds on Cat Command, a Caterpillar solution that enables workers to automate functions and remotely operate construction equipment without having to be in the cab.

Cat MineStar Command allows miners to automate mining processes, control one machine remotely, automate many types of equipment in a mixed fleet, “or implement a completely autonomous fleet of haul trucks that operate around the clock with no human intervention,” reads Caterpillar literature. Equipped with Lidar and other high-tech tools, MineStar Command for hauling enhances safety while boosting productivity and cutting costs, says Caterpillar.

Caterpillar’s solution might soon be in high demand, given that the autonomous mining vehicle market is poised for a massive lift-off.

“The global autonomous mining truck market is expected to be valued at $1.6 billion in 2025, and is projected to reach $12.5 billion by 2035, growing at a CAGR (Compound Annual Growth Rate) of 23.2 percent from 2025 to 2035,” states an Allied Market Research study released in October 2022.

The Asia-Pacific region will likely be the main market for autonomous mining trucks, while underground LHD (load, haul, dump) loaders “are projected as the most lucrative segment,” continues the study.

“A mine site is an ideal environment for autonomous vehicles. Haul trucks travel predictable routes at predictable speeds. They go from fixed point to fixed point, usually from a loading tool to a dump truck and back,” states Caterpillar, adding that AVs reduce problems caused by tired or distracted human drivers.

As mentioned, mines are generally situated in isolated locations. The real test of AV technology will take place when fully driverless vehicles start routinely making deliveries on public roads (as opposed to small-scale pilot programs). To this end, “Commercial ‘driver out’ operations for autonomous trucks are likely to start on select highway routes [in the United States] beginning in 2024,” stated market analyst Stephen Volkmann in Investor’s Business Daily.