One of the most transformative times in history, the Industrial Revolution forever changed the course of how the world lives and works. Starting in 18th century Britain and spreading to other countries, the Industrial Revolution resulted in small-scale workshop manufacturing of goods like clothing and pottery shifting to mass production.

Thanks to inventions like the Spinning Jenny—a revolutionary multi-spindle machine—it became possible to draw thread from eight spools at once. A vast improvement over traditional spinning wheels turning a single spool at a time, James Hargreaves’ 1764 innovation, patented in 1770, soon grew to 120 spools. Unlike the slow processes of the past, cloth could be made quickly, efficiently, and in greater quantities.

The decades to come saw the Industrial Revolution—earning its name from the rapid and revolutionary way it changed society—bring many changes. Landmark machines came into existence, such as the steam engine, powered iron mills, distilleries, paper mills and flour mills. Meanwhile, the rise of the steam locomotive and steam-powered ships made transporting goods faster and more economical than by horse or sailing vessels.

Power at a price

Although it introduced many benefits to the world, including increased innovation, faster and more economical production, and better methods of transportation, the Industrial Revolution created a new array of problems. These included appalling child labour practices, festering urban slums as people migrated from the country in search of industrial jobs, and often poor and dangerous working conditions.

Major cities saw untreated waste dumped into rivers and were blanketed daily in dense black smoke, the result of burning coal to fuel manufacturing.

Fueled by coal, the first Industrial Revolution made way for the second in the 1870s, powered largely by gas, oil, and early practical uses for electricity. Fast-forward 100 years and the third Industrial Revolution saw the rise of nuclear energy and electronics. Starting in 2000, the Fourth Industrial Revolution is notable for the Internet, cloud and digital technologies, predictive maintenance, and renewable sources of energy.

As manufacturing has evolved, our collective awareness of protecting the planet has grown as well. Worldwide, manufacturers, schools, and organizations are dismantling the outdated belief that manufacturing is “dark, dirty, and dangerous” through education. Bodies like The Manufacturing Institute and its founding partner, the Fabricators & Manufacturers Association, are behind MFG Day. Open to students, parents and/or educators, MFG Day offers tours of manufacturing facilities, innovation centres, offices or other sites, information, career days or job fairs, and plenty of learning opportunities.

Now, manufacturing is undergoing another transformation with green sources of power, like wind and geothermal. It’s no longer unusual to see massive facilities with solar panels on rooftops, and even on the canopies covering parking areas, capturing free energy.

Across North America and Europe, well-known manufacturers like Johnson & Johnson, Toyota, Owens Corning, and Del Monte Foods have solar arrays at their plants. Yet despite these initiatives, many factories worldwide are still powered by fossil fuels.

Room for improvement

Although safer and cleaner than in the past, manufacturing still needs to work on reducing harmful emissions.

According to UK-based Eco Experts, the biggest emitters of global greenhouse gas (GHG) by industry are energy (electricity generation and heating) at 15.83 billion tonnes, and transportation at 8.43 billion tonnes. At number three are manufacturing and construction, generating 6.3 billion tonnes of GHG emissions every year.

When measuring global GHG, five key kinds of pollution are examined: water, soil, air, noise, and light. Different greenhouse gases are emitted through activities such as deforestation, biomass decay, agricultural activities, fertilizer use, and many others.

Manufacturing and industry are responsible for GHG emissions stemming from burning fossil fuels for energy, along with chemical, mineral and metallurgical processes, waste management, and other processes. Depending on the sector, these gases can include carbon dioxide, methane, nitrous oxide, fluorinated gases (F-gases) and hydrofluorocarbons, perfluorocarbons, and sulphur hexafluoride. Black carbon, better known as soot, is created by burning fossil fuels and wood, and contributes to climate change.

Solutions great and small

As environmental awareness grows, so does the need among manufacturers for stricter regulations, limits on pollution, better use of resources, and transitioning from fossil fuels toward renewable sources of energy. Along with the benefit of reducing manufacturers’ carbon footprints comes cost savings and greater accountability to the company itself, its shareholders, and the public.

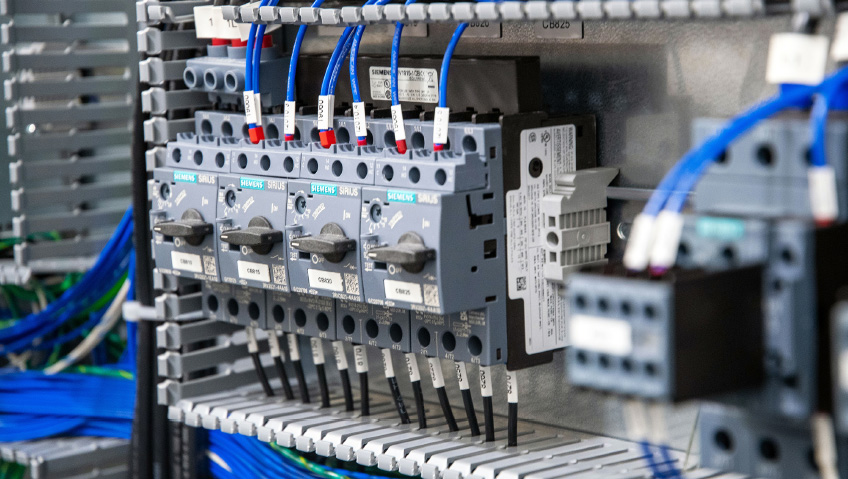

Best of all, many of the measures manufacturers can take to reduce greenhouse gases make economic sense, or are even free. Just as homeowners sign up for programs to monitor the amount of electricity they consume, manufacturers can take advantage of Smart meters, electronic devices measuring energy consumption, voltage levels, and more. Tracking power in near-real time, some meters also calculate when consumption is at its highest. Even minor changes, like turning off lights, computers, and machines that don’t need to be on standby, result in savings and fewer carbon emissions.

Many industries consume vast amounts of water for manufacturing and processing. Less of a resource and more of a commodity today, water can often be recycled and reused. Even hot, untreated water can be repurposed and directed through pipes to heat facilities in winter before it is cleaned. And much like electricity, water consumption is metered today, meaning the less manufacturers use, the lower the cost.

Some other low-cost initiatives include reducing the amount of packaging and minimizing office waste; reuse, repair, recycling, and remanufacturing (instead of disposal); and even encouraging ride-sharing programs to work. Manufacturers can also significantly reduce carbon emissions by switching to green energy suppliers providing power derived from wind, solar or other renewables where available. Finding lightweight, environmentally friendly alternatives to plastic packaging, such as biodegradables—especially in food and beverage manufacturing—is another great way to help the environment.

Although requiring upfront investment, acquiring the tools and technologies to reduce carbon emissions pays off in the long term. While purchasing cheaper machinery and parts may seem to make financial sense, this often ends up being more expensive, since poorer-quality components and equipment don’t last as long, break down more often, and need to be replaced, which creates more environmental waste.

Better machinery also tends to be more energy-efficient. Scrupulous maintenance of existing equipment also benefits manufacturers and the planet, extending equipment lifespans, enhancing performance, creating less heat, and using less power. There’s often a strong payoff in having fewer, better-quality machines than higher numbers of less-efficient ones.

Another recent innovation in manufacturing, 3D printing, is fast replacing traditional manufacturing methods like moulding. Also known as additive manufacturing (AM), this technique creates far less waste since material is not being removed and discarded—as sometimes is the case with subtractive processes—but added as needed. Substituting traditional materials with sustainable choices such as renewable bamboo instead of non-recyclable plastic in the manufacturing process is yet another way to offset carbon emissions.

For manufacturers seeking to upgrade or build new facilities, there’s the option of green building. Although a significant investment, structures made according to LEED specifications are simply better, improving efficiencies and saving money. LEED buildings are responsible for far fewer carbon emissions than their traditional counterparts and are healthier for the building occupants.

Although manufacturing can’t turn the clock back hundreds of years to the start of the first Industrial Revolution, much can be done with the technologies of today to make the world a cleaner, healthier place.