Think-PLC designs and builds new automation control systems and keeps legacy control systems running long after they were installed. Among key services offered by this Lexington, North Carolina-based company are installation, fabrication, manufacturing, consultation, training, maintenance, and repairs. The company is also a solutions partner with German technology giant Siemens, and works with clients worldwide in manufacturing, machine building and other sectors.

“We feel like we can make an impact not only to our customers but on a global scale by providing services around industrial automation,” states company Founder and Chief Executive Officer Bobby Cole.

For all its technical expertise, the fledgling firm—Think-PLC was founded in June 2019—excels at relationship building and helping people under difficult circumstances.

“We’re all pretty innovative. The difference is how we manage our systems and how we look at people,” he says, reflecting on his competition.

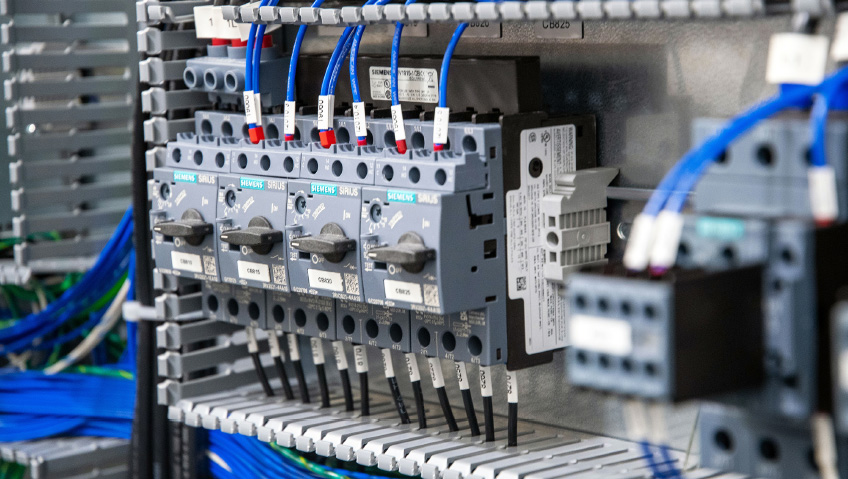

As befitting the company name, programmable logic controller (PLC) devices—the core elements of industrial control systems—are central to its mission. PLCs are used to monitor performance, collect, and transmit data, and control automated machinery, robotics, and processes.

“Programmable logic controllers are industrial computers… People have programmable logic controllers in their factories running machines; they have them in jails keeping the doors closed; they lift and close bridges. The electrical controls and programmable logic controller itself is what we specialize in,” explains Cole, adding, “We are ‘controls’ guys.”

Think-PLC contracts out some duties but self-performs most of its own work, with manufacturing and fabrication performed at the North Carolina facility. Specializations include panel building, cable assembly, and machine shop services. The firm has certification from both UL and National Fire Protection Agency (NFPA). Based in Illinois, UL offers audit-based certification. Headquartered in Massachusetts, the non-profit NFPA sets national codes for ‘safe electrical design, installation and inspection,’ in its own words.

UL “is the quality standard for control panels we manufacture here. We provide a design that is to UL and NFPA spec,” states Cole.

Think-PLC also maintains a branch in East Tennessee staffed by “house engineers for local deployment in that territory,” he says.

With twenty-two employees, the company wants new hires with certain qualifications. “Eighty percent of the time, what we’re interviewing for is a controls engineer, so we’re looking for someone with some kind of tech school background in the industrial automation sector.” The company employs a multi-step ‘slow hire’ process that involves interviews, a written test to gauge an applicant’s awareness of industrial standards and industry knowledge, and a remote test with “a real-world system,” he continues.

It also uses a profile test called ‘The Working Genius’ developed by business writer Patrick Lencioni, to gain a sense of the strengths and weaknesses of people who want to join the staff. Once hired, Think-PLC staff members receive complete medical benefits and unlimited, paid time off.

Being empathic and able to work well with others are additional qualities that might help get one hired. The company is proud of its stellar service and will dispatch technicians around the world to update, repair, and maintain client systems or provide training.

“We’re definitely, believe it or not, in a relationship business,” states Cole. “When you need help, and you’re in dire straits, we’re the last-ditch service that gets your livelihood back.”

By this, he is referring to Think-PLC’s role in providing end-of-life care for legacy automation controls. As he notes, buying a new manufacturing machine or industrial system can be enormously expensive and disruptive. “It’s a big deal. It’s like why we keep a car for ten years: you don’t want to spend money on a new car,” he points out.

At “a tenth of the cost of a new machine,” and a fraction of the hassle, the company can provide upgrades in the form of new controls, new capabilities, and technical support to keep industrial automation systems in good working condition, he says.

In another example of relationship building, Think-PLC formed a partnership with Siemens, which makes industrial automation controls and a slew of other sophisticated products. Siemens solutions are used around the world in sectors such as manufacturing, transportation, industry, healthcare, and infrastructure.

“A big reason we are a Siemens solution partner is because of the lifecycle they offer for their products. They go way longer than their competition,” Cole adds.

Being involved with Siemens also helps Think-PLC stay on top of technological trends. Over the past few years, there has been much buzz about the internet of things (IoT), connectivity, remote monitoring, and artificial intelligence (AI) within manufacturing and industrial circles. Siemens has already been experimenting with solutions that use AI.

Information gathering is central to all these trends. “I think getting data is ever so important to manage your business,” he states. “All the manufacturers that make the control equipment we use have added some level of analytical data collection or connectivity to their product.”

Previously, he was involved with another company that offered similar services. That firm had three owners, each with a different viewpoint on how to run the business. This proved unworkable, so he, along with some colleagues from the older firm, split to launch the new company.

Cole put all his finances into Think-PLC but had a sense of confidence about the business, born of his long experience as an entrepreneur and his skill in building relationships. In 2020, he joined a corporate leadership organization called Vistage which offered further inspiration. The global organization offers CEO coaching and advisory networks made up of fellow executives.

“It’s a C-suite-level peer group. I’d always asked for that in the past. The other business partners were not vulnerable enough to talk about finances and struggles with other people. I wanted that peer accountability,” says Cole.

Vistage “has become a big part of my life now. It’s not just about being the best controls engineer anymore. Now it’s about being the best leader I can be. To create the best company that somebody else would want to be proud of,” he continues.

Membership in Vistage helped guide him through the COVID crisis. He was in Melbourne, Australia “when COVID started to be a thing in March 2020,” he recalls.

Cole was urged to get home quickly by colleagues who feared that he might not be able to return to the United States given increasingly strict travel restrictions. He made it back to headquarters and had to cope with the virus’ impact on his workforce and the bottom line. As part of Vistage, he was able to share insights, advice, and suggestions with fellow corporate leaders, which helped immensely during the upheaval.

Business-wise, Think-PLC did well during the pandemic, doubling its staff in 2020. Many of the company’s clients have connections to the food and beverage sector, which experienced booming revenues as housebound people stocked up on groceries or ordered in more frequently.

Just before COVID struck, the company received a huge assignment. “We had one of the largest projects in my career on the horizon going into March 2020,” says Cole.

The project involved donut maker Krispy Kreme, one of its largest customers. The donut chain wanted to build a flagship store in Times Square in New York City. Construction was delayed because of the pandemic but Think-PLC did not throw in the towel and continued to work on the project.

“We spent most of [2020] hunkered down working on that project. Me and my team spent time in downtown New York City helping facilitate Krispy Kreme donut machines being installed,” he says. The Krispy Kreme Times Square flagship store eventually opened to great fanfare in mid-September 2020 and now serves donuts around the clock.

While Think-PLC flourished on the business front during COVID, the virus is still causing headaches. Cole cites pandemic-related supply chain issues as his biggest challenge at present.

“It’s all we talk about. Four hours a day, I am chasing parts down. We have meeting after meeting about what are we going to do because we’re not getting parts on time,” he states.

Supply woes aside, the company continues to do extremely well. The company currently does about $7 million in revenue a year, all without salespeople or active promotion, as the firm is “a largely word-of-mouth business,” according to Cole.

The company would like to open new branches down the road and might take a more proactive approach when it comes to promotion and sales. Recently, it hired its first mechanical engineer and now has a staff machinist to broaden the company’s service offerings.

“Five years from now [I see] organic growth. I can also see over the next five years finding a strategic acquisition,” Cole states. “I think I’ve made it clear what’s important to us. It’s not sales, sales, sales. It’s not profit, profit, profit. It’s people, people, people,” he says.