JN White is a fast-growing firm headquartered in Perry, New York, that manufactures custom graphic overlays, membrane switches, display backlighting, and complex user interfaces. Its primary services are rapid prototyping, custom assembly, manufacturing engineering, vendor managed inventory, and switch testing. The company adheres to strict industry standards to maintain consistent quality.

The single biggest change since the company was profiled by Manufacturing in Focus in May 2019 comes in the form of an acquisition. In early 2021, JN White purchased ECI Screenprint which was a direct competitor that screenprints flexible circuits and graphic overlays. Based in Watertown, Connecticut, it has been rebranded as ECI Technologies, a JN White company.

“It’s a company that does essentially the same thing we do. Without question, that’s the biggest thing that’s gone on since 2019,” says Vice President of Sales Ken Boss.

The company serves the industrial electronics, agricultural, medical device, consumer appliance, defense, and automotive sectors. “We’re really positioning ourselves as the manufacturing experts for medical device manufacturing and department of defense and related companies, both OEMs and first-tier suppliers,” notes President Jason Aymerich.

To this end, JN White has ISO 9001:2015 certification for manufacturing and International Traffic in Arms Regulations (ITAR) certification that is required for doing business in the U.S. defense / military sector.

The company is also compliant with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) as well. These European manufacturing standards limit the use of heavy metals and toxic substances during production.

“We are also pursuing our NIST 800-171 and CMMC Level 2 compliance, which is very important for Department of Defense customers,” he adds. CMMC—Cybersecurity Maturity Model Certification—as developed by the U.S. Department of Defense, contains different levels of compliance.

JN White kept extremely busy fulfilling orders for medical device manufacturers during the worst of the COVID crisis. The firm also produced its own line of face shields, a much-in-demand bit of personal protective equipment.

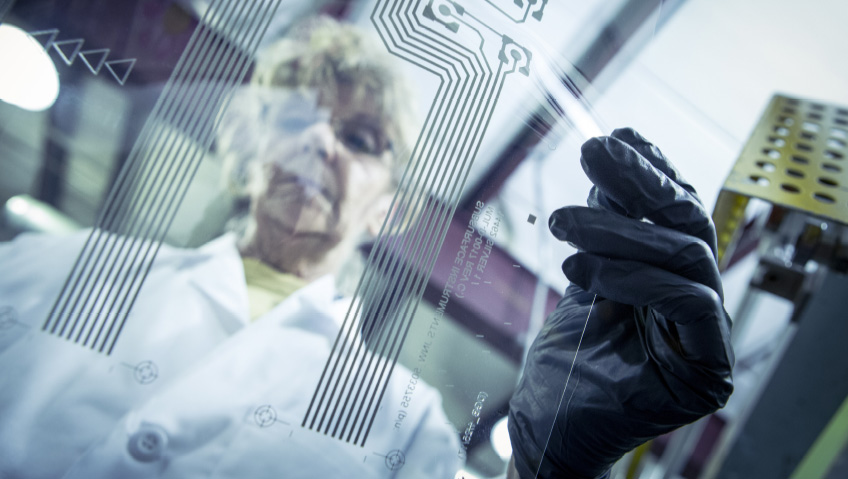

Its non-COVID medical work centers on interface assemblies and labeling. For defense-related products, the company provides manufacturers with keypads, user interface panels, and extreme environment / crucial-use labels. It also creates custom membrane switches for the industrial electronics, consumer appliance, agricultural, and automotive sectors.

“Everything we produce is custom. Ninety-five percent of what we manufacture is for an OEM. It could be as simple on buying a label stock from a company like 3M, printing it, cutting it, and turning it into a finished product for a customer,” says Boss. “We also get into more complex user interfaces. We might be purchasing printed circuit boards to our customer’s specs, manufacturing the graphic overlay, then assembling and testing [everything] as part of our manufacturing process.”

Services are performed in-house, although “Depending on the complexity, we may subcontract,” as needed, he continues, adding that at present, design engineering for manufacturing is the service that brings in the most revenue.

The company’s excellent reputation centers on three main factors: “our technical abilities, impeccable quality, and excellent customer relations,” says Aymerich. “Once our customers are onboard, we have a near frictionless experience in the way we interact which makes the entire process of working with JN White streamlined and easy to manage,” he adds.

This frictionless experience stems in part from JN White’s commitment to lean initiatives. Several company executives have engineering degrees, or Six Sigma designations such as black and green belts, while lean training is emphasized for all staff. While efficiency is important, product innovation remains top-of-mind as well.

Including ECI, the company now employs roughly 123 people, up from approximately 115 this time last year, says Aymerich. When hiring new staff, applicants with “deep industry knowledge,” a good work ethic and connections are preferred. Patience is also required, given “The sales cycle in our industry is particularly long,” he says. “We are actively pursuing more technologically complex projects. By virtue of that fact, the development cycle on the customer side is longer. Some of our larger programs have been in development for two or three years.”

Clearly, JN White is doing something right. The company won the Wyoming County 2021 ‘Large Business of the Year Award,’ given by the Wyoming County Chamber of Commerce and Tourism. That same year, it was a finalist for the ‘Manufacturing Innovation Award’ presented by the Rochester Business Journal. In 2022, JN White received a Greater Rochester Quality Council (GRQC) silver award as well as Aymerich being included on the Rochester Business Journal’s ‘Power 50 in Technology’ list.

The company has come a very long way over the decades. It was founded in 1960 by James Neel White (J.N.), an Air Force veteran who served with distinction as a fighter pilot in World War Two. Originally called J.N. White Designs and based out of the founder’s home, the company had a much narrower focus in its early days. “At our onset, we were screen printers to the core, mostly doing labeling,” recalls Boss.

Gradually, the company added new services and new markets. Growth came about through both expansion and acquisitions. Since the early 1990s, it has purchased four businesses, including a company in New York State and two divisions of the same firm in Pittsburgh, Pennsylvania. ECI is the latest purchase. The company name was changed to JN White in 2016.

James White’s son, Randy White, is currently President and Chief Executive Officer. In 2019, Randy White hired Aymerich because he possessed experience in rapidly-growing companies. To complement Aymerich’s skill in driving growth, the company puts a great deal of energy and effort into marketing.

“For a company our size, we have an aggressive marketing plan,” states Boss. Internet marketing includes “everything from social media—LinkedIn, Facebook—to Google searches. Our marketing presence is really top-tier for our industry, even up against some of our largest competitors. We have a fully-established marketing department, marketing program, and marketing budget, and a lot of—if not the majority of our new prospects and leads right now—are coming in through those marketing efforts.”

The company also routinely attends trade shows and maintains a lively online presence with a detailed website and blog. The blog contains a regular ‘Ask Ken’ column in which Boss answers industry-related questions on topics such as backlighting, graphic overlays, labels, and membrane switches.

While they can’t speak to specific plans right now for further corporate purchases, the company’s management and ownership remain open to the idea.

“We are looking at other acquisitions and also licensing technology and industry-specific Intellectual Property. We’re looking at acquisitions both in our field and in adjacent technologies, like [printed circuit board] manufacturing, maybe wire harnesses—things that our products would be incorporated into. We are finalizing a patent and intellectual property agreement for a very novel backlighting technology, and we believe that will help open the field for additional growth for JN White,” Aymerich states.

The company wants to continue innovating and enhancing existing products and services, while also developing new wares.

“I think, ultimately, we would like to identify a product somewhere in the wearable medical device arena that we would manufacture and market as our own JN White product, but that’s yet to be determined. I believe it will absolutely be somewhere in the field of printed and flexible electronics,” says Boss.

For all that, there have been a few bumps on the road as of late. COVID might have driven product development and sales, but the pandemic has also wreaked havoc on global supply chains. Supply issues represent the biggest challenge facing the company at present. “The more we get into electronics, the more supply chain becomes a concern, specifically, the availability of electronic components that go into some of the custom-printed circuit boards,” he admits.

Supply chain delays and disruptions have affected business in another way too. Faced with their own supply chain challenges, original equipment manufacturers are taking longer to build products or making fewer of them which can, in turn, mean less business for JN White.

“If we’re doing the printed instrumentation cluster in an automobile and they’re building less automobiles because they can’t get computer chips, then they don’t need our product either,” explains Boss.

These issues might cause headaches but are not likely to interfere with the company’s overall momentum. Company leaders offer an optimistic forecast, centered on continued growth.

“I see JN White in five years being roughly double the revenue we are currently and continuing to expand our capabilities to include more and more complex products. We want to own the top half-inch of our customer’s product. Instead of just doing overlays and membrane switches, we’re doing [printed circuit boards] board and wire harness or flexible circuits that are associated with that and continuing to add more value to our customers,” states Aymerich.