The automation industry is at a crossroads. Facing challenges from seasoned workers retiring and too few apprentices coming up, to tight budgets and ever-changing technology, the sector is critically short of experienced labor – which is where Industrial Plant Services (IPS) comes in.

IPS – with all its installation, integration, and technical support and maintenance capabilities – has the right people for the job.

From preventative, predictive, and corrective maintenance to line build integration and home line commissioning, the company’s cross-trained labor force helps automation industry clients reach higher levels of efficiency.

“Our core business is to provide supplemental maintenance and tech support personnel to industry, whether it’s automotive, aerospace, or general manufacturing,” says IPS President and Chief Executive Officer Greg Aliotta, Sr. “It doesn’t matter whether it’s a widget or full-size truck; the equipment is automation.”

When he joined Macomb Township Michigan-based Industrial Plant Services in 2017, Aliotta brought decades of experience with him. Spending much of his previous career with a major auto manufacturer, Aliotta was in charge of launching new programs and the maintenance department at the company’s fastest-running plant, with all skilled trades and tech support personnel under his management.

Part of the challenge was getting internal skilled trades to accept overtime that was available to perform both preventative and corrective maintenance on equipment. With that, contractors came to fill the void in the system.

To address the issue, Aliotta devoted considerable time and energy to putting together presentations and showing contractors the ropes — including the fixing of machinery, and the sourcing of parts — which saw his team spending more time working with contractors than doing their own jobs.

In the past, the UAW (The International Union, United Automobile, Aerospace and Agricultural Implement Workers of America) dedicated time to training apprentices through partnership programs, which have gone away. Seeing the number of skilled trades shrinking, Aliotta knew something had to change.

When he took over Industrial Plant Services, Aliotta wanted to provide a team of individuals rich in appropriate in-plant skills, and with good knowledge of how to operate primarily from a maintenance capability standpoint.

To accomplish this, he created a team of experienced automotive-industry personnel. This firsthand knowledge allows IPS to appreciate and address challenges the industry is going through on a day-to-day basis.

“We understand their systems very well and are really a part of their integrated team when we go in. That’s the way we like to approach our customer base, going in as a partner and a supplemental portion of their team, working on a common goal,” Aliotta says.

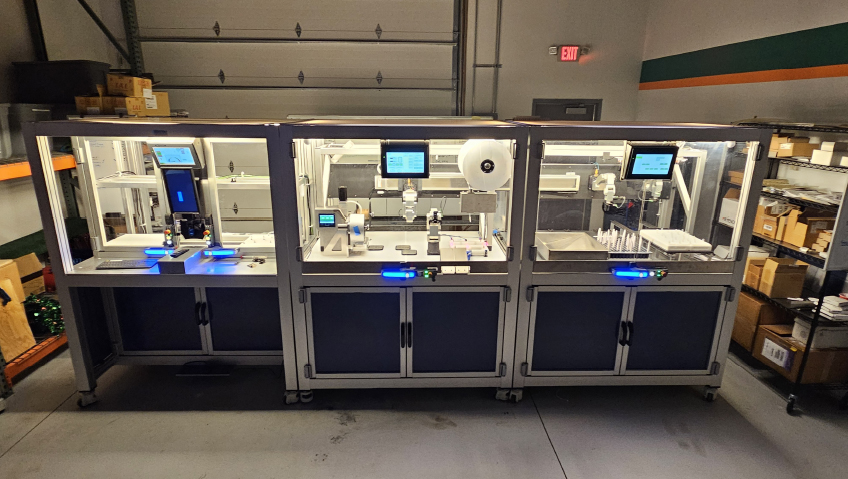

Industrial Plant Services is not a manufacturer but provides skilled maintenance technicians for work in facilities, such as installing equipment and kits for program changes and engaging in the manufacturing process with the owner, including planning and continuous improvement items.

With much of the world focused on reducing greenhouse gases by 2030, many industries are shifting towards electric power, which is true for automotive in particular.

This transformation involves updating and re-tooling some existing machinery, and the purchase and installation of new technology including robotic systems and conveyors. The result is growth in the automotive sector for IPS as manufacturers plan for downtime to strategically address current developments in their production systems.

The location of IPS in Michigan, at the heart of American auto manufacturing, has its advantages.

“We’re in the Motor City, and there’s a lot of manufacturing here,” says Aliotta. “All the major automotive manufacturing integrators are here. From a service perspective – if you’re tied in with the integrators and the major domestic automotive – even though the plants are spread across the U.S., everything for the domestic auto comes out of Michigan.”

Even with the increase in automotive, Industrial Plant Services is focused on broadening its customer base to diversify its portfolio and revenue stream.

When Aliotta came on board, one of his goals was improving total revenue 20 percent year-over-year, a goal which was exceeded last year by about 60 percent, much of it due to automotive.

Despite the increase, the company perceives the industry as cyclical. As equipment is updated it will require less attention, until it deteriorates and requires a change of components because of wear and tear.

From a staff perspective, IPS runs lean, typically with 15 to 20 employees. However, since the company is a signatory to skilled labor, numbers fluctuate from 20 skilled tradespeople to 250 during a shutdown.

For the aerospace sector, the company takes on projects tied to automated processes, like robotic paint shops or robotic assembly systems. “Whether it’s a truck or a widget, it doesn’t matter. Automation is automation, and it requires attention and service from both a preventative and corrective maintenance perspective,” says Aliotta about IPS, another of whose clients is a large company making powersports and off-road vehicles.

At IPS, the safety of skilled laborers working in construction-type activities is an overriding priority.

The company’s motto is ‘no project is so urgent or important that we cannot take the time to do it safely.’ With a strong safety program in place, safety tasks are implemented from the moment IPS takes on a project, which provides multiple benefits.

Not only does this compel the team to look at the work from a safety perspective, but it also helps clarify the order in which the company should perform its tasks, streamlining the whole process.

Through conversations about safety and engagement with employees – which can include pre-task plans or Safety Failure Mode Effects Analysis (SFMEA) – IPS ensures that plans match the work that people will perform, that all potential hazards have been identified, and that all steps are taken to eliminate identified hazards.

“If we run into something that we didn’t foresee we immediately stop, pull everybody back, look at what this newly identified hazard might be, and get everybody shaking their heads in the same direction about how to approach things before we step into it,” says Aliotta.

“Safety planning is key, and when you drive a culture of safety, you get folks engaged. It also drives efficiencies automatically.”

To further ensure protocols are in place, the company has a full-time safety director who came out of General Motors, which is known for having the most stringent safety mandates in the industry. As a result, IPS is ISNetworld A-rated, with zero injuries or recordables.

Helping clients in automotive, aviation, healthcare and pharmaceuticals, manufacturing, metals, plastics, food and beverage, and other sectors, IPS is addressing rapid changes and growth in automation.

One solution the company is working on is the ability to assess and address issues with machinery and equipment remotely. “Everybody wants to use the iPad and the iPhone nowadays and not get up to go and see or touch the real issues, so I’m looking at the future of automation having that remote capability to operate, which is important,” he shares.

“Whether you are a restaurant that has some of your machinery down, like a McDonald’s ice cream machine, or you’re an auto manufacturer, we are working on solutions to go into facilities remotely and have the capability to operate or tie in to a particular machine and break that machine down into levels, whether to order parts or to point a technician at what to repair and how to do it. We are looking at doing that remotely as we speak.”